Ultrasonic coupling supergravity rotary packed bed and application thereof

A super-gravity rotation and ultrasonic technology, applied in chemical/physical/physical chemical processes, mixers, chemical instruments and methods of applying energy, etc., can solve the problem of inability to adjust the reaction rate, failure to strengthen, and easy clogging of the rotating packed bed and other problems, to achieve the effect of improving efficiency, small space occupied by equipment, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

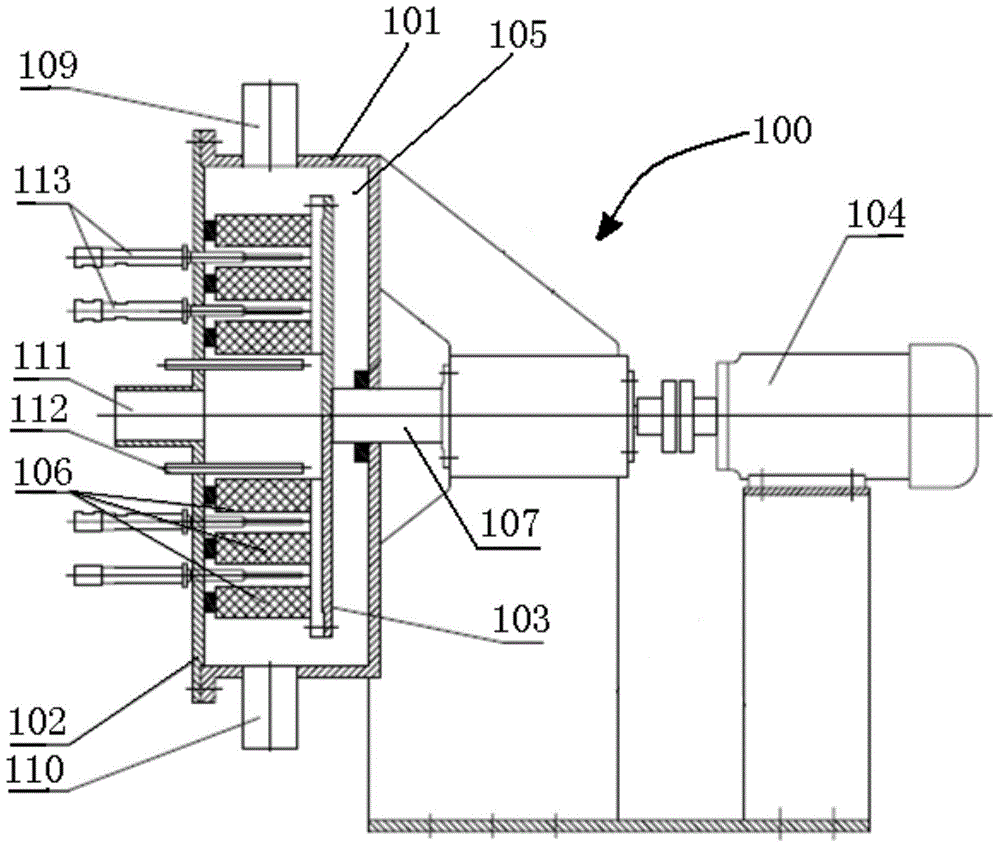

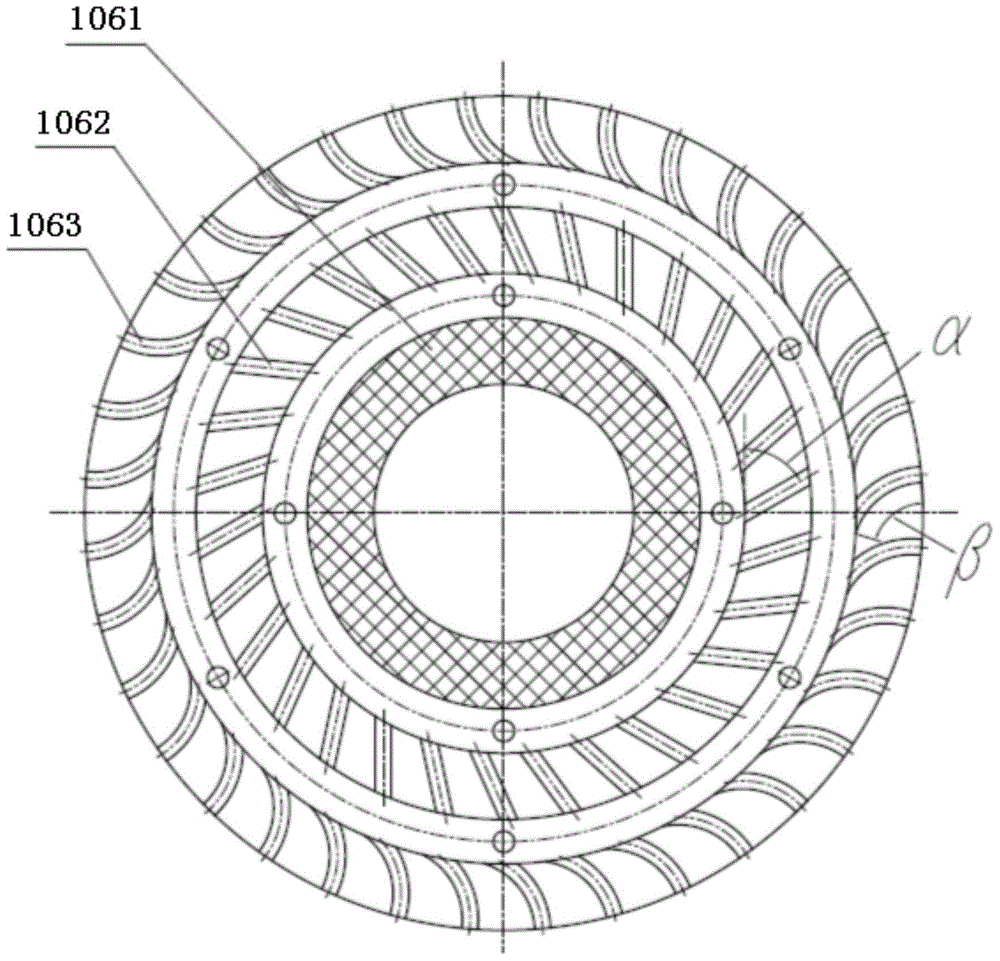

[0041] see figure 1 As shown, an ultrasonic coupling supergravity rotating packed bed 100 includes a housing 101, an end cover 102, a rotor 103 and a transmission device 104; the housing 101 and the end cover 102 form a closed cavity 105, in which 105 is provided with a rotor 103, and a packing ring 106 is provided on the rotor 103; the rotor 103 is connected with the transmission device 104 outside the airtight cavity 105 through a rotating shaft 107; the housing 101 is provided with a gas inlet 109 and a liquid outlet 110 ; The end cover 102 is provided with a gas outlet 111 and a liquid input distributor 112, the liquid input distributor 112 penetrates from the end cover 102 and extends into the central cavity of the rotor 103, and is close to the innermost packing ring 106 The packing rings 106 are three rings of reactive packing rings with different diameters arranged concentrically, and the annular space between adjacent packing rings 106 is provided with an ultrasonic g...

Embodiment 2

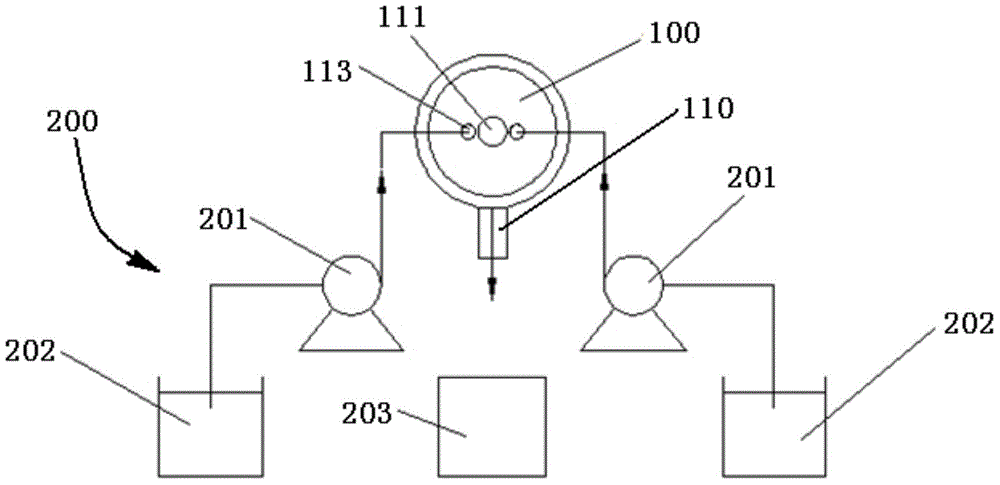

[0048] see image 3 As shown, a liquid-liquid reaction system device 200 comprising the above-mentioned ultrasonically coupled high-gravity rotating packed bed includes an ultrasonically coupled high-gravity rotating packed bed 100, and the ultrasonically coupled high-gravity rotating packed bed 100 is provided with two liquid input distributors 113 , each liquid input distributor 113 is connected to the outlet of the pump 201 through a pipeline, and the inlet of the pump 201 is connected to the feed tank 202 through a pipeline; a waste liquid tank 203 is provided below the liquid outlet 110 of the ultrasonic coupling supergravity rotating packed bed 100 .

Embodiment 3

[0050] see Figure 4 As shown, a gas-liquid reaction system device 300 comprising the above-mentioned ultrasonically coupled high-gravity rotating packed bed includes an ultrasonically coupled high-gravity rotating packed bed 100, a feed pump 301, a feed tank 302, a gas source 303, and a gas control switch 304 , a gas flowmeter 305 and a waste liquid tank 306; the feed tank 302 is connected to the inlet of the feed pump 301 through a pipeline, and the outlet of the feed pump 301 is coupled to the liquid input distributor 113 of the supergravity rotating packed bed 100 through a pipeline Connection; the gas source 303, the gas control switch 304 and the gas flow meter 305 are connected to the gas inlet 109 of the ultrasonically coupled supergravity rotating packed bed 100 through pipelines in turn; the liquid outlet 110 of the ultrasonically coupled supergravity rotating packed bed 100 A waste liquid tank 306 is arranged below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com