Method and apparatus for producing exterior wall self-heat preservation composite ecological light wall board

A technology of light-weight wallboard and production method, applied in the field of construction machinery, can solve the problems of low degree of mechanization, low production efficiency, inability to use external walls, etc., to improve the degree of product diversification, shorten the production cycle, and improve product quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

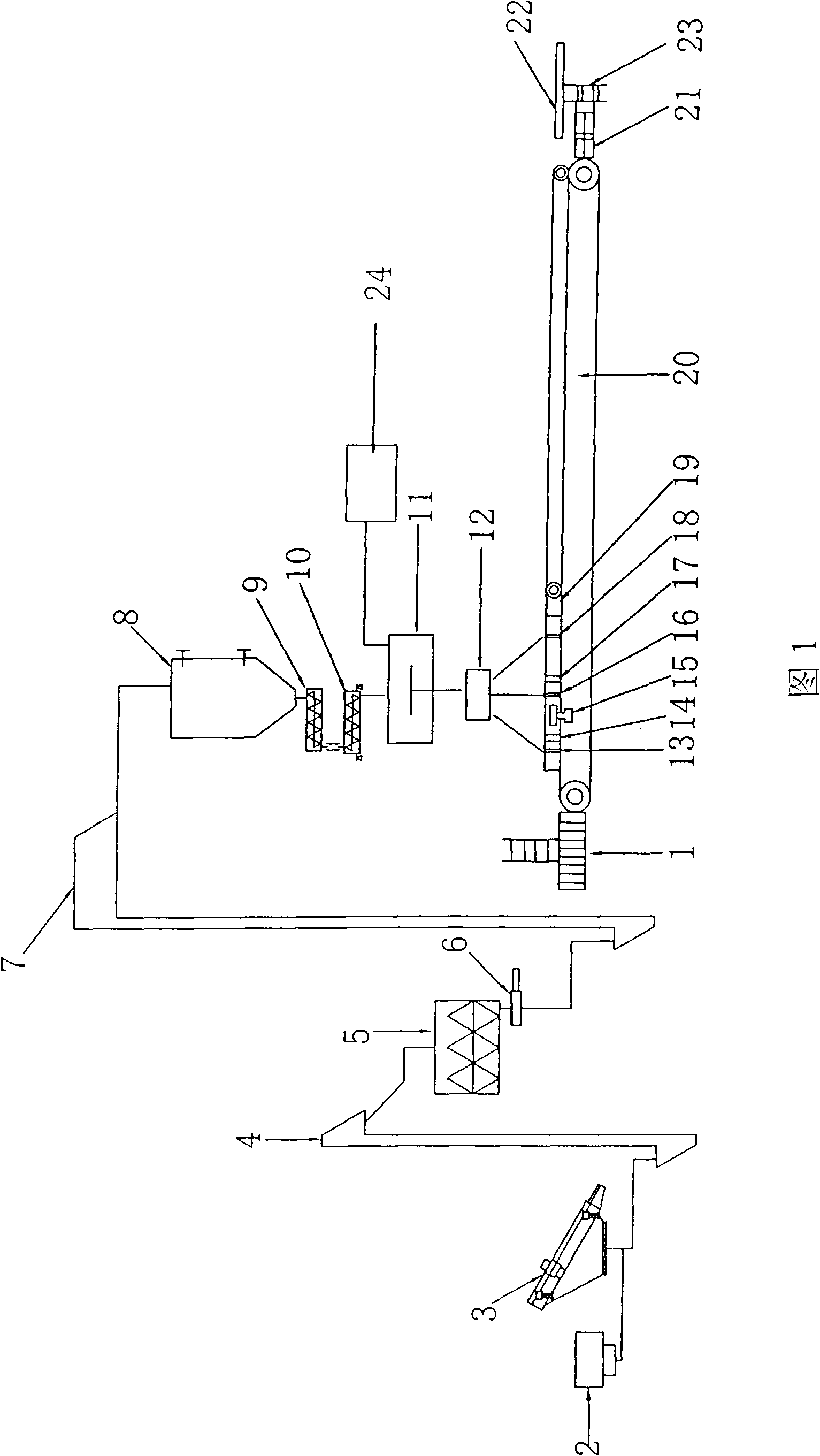

[0028] Embodiment 1, referring to accompanying drawing 1, the equipment of this embodiment of the present invention comprises base plate feeding frame 1, conveyor 2 and grading screen 3 each one, hoist (4,7) two. Wherein the conveyor 2 adopts the commercially available SSJ-I type conveyor, and the grading screen 3 adopts the commercially available FJS-I type 80 mesh grading sieve. The elevator 4 in the two elevators adopts the commercially available GYTS-I type bucket elevator conveyor, and the elevator 7 adopts the commercially available GYTS-II type bucket elevator conveyor. There are 8 storage tanks, which are CG-I type storage tanks of the "Wall God" series products in Hunan, China. Conveyor 9 with weighing scale 10 is two, all adopts commercially available SSJ-I type screw conveyor. And the mixer is also provided with two sets, wherein the mixer 5 for mixing the dry powder adopts the GYJ-I type mixing mixer of the "Wall God" series product of Hunan, China; the mixer 11 f...

Embodiment 2

[0038] Embodiment 2, the grading sieve 3 in the equipment of this embodiment adopts commercially available FJS-I type 120 mesh grading sieve; 2 or EPS-2 pressurized distributor, all the other are the same as embodiment 1; Utilize in the production method of the exterior wall self-insulation composite ecology lightweight wallboard of this equipment, step (1) is pressed the powdery batching of high-strength water-resistant gypsum formula compatibility Sieve through a 120 mesh vibrating sieve, and all the other steps are also the same as in Example 1.

[0039] The production method and equipment of the self-insulating composite ecological light-weight wallboard for external walls of the present invention have been proved to have remarkable effects through tests and fully meet the design requirements. From the input of raw materials to the aging of products in the warehouse, this equipment operates continuously throughout the whole process, with low energy consumption, short cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com