Complex heat-preservation roof and construction method thereof

A technology of composite thermal insulation and construction method, applied in the field of building components, to achieve the effects of easy operation, simple process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

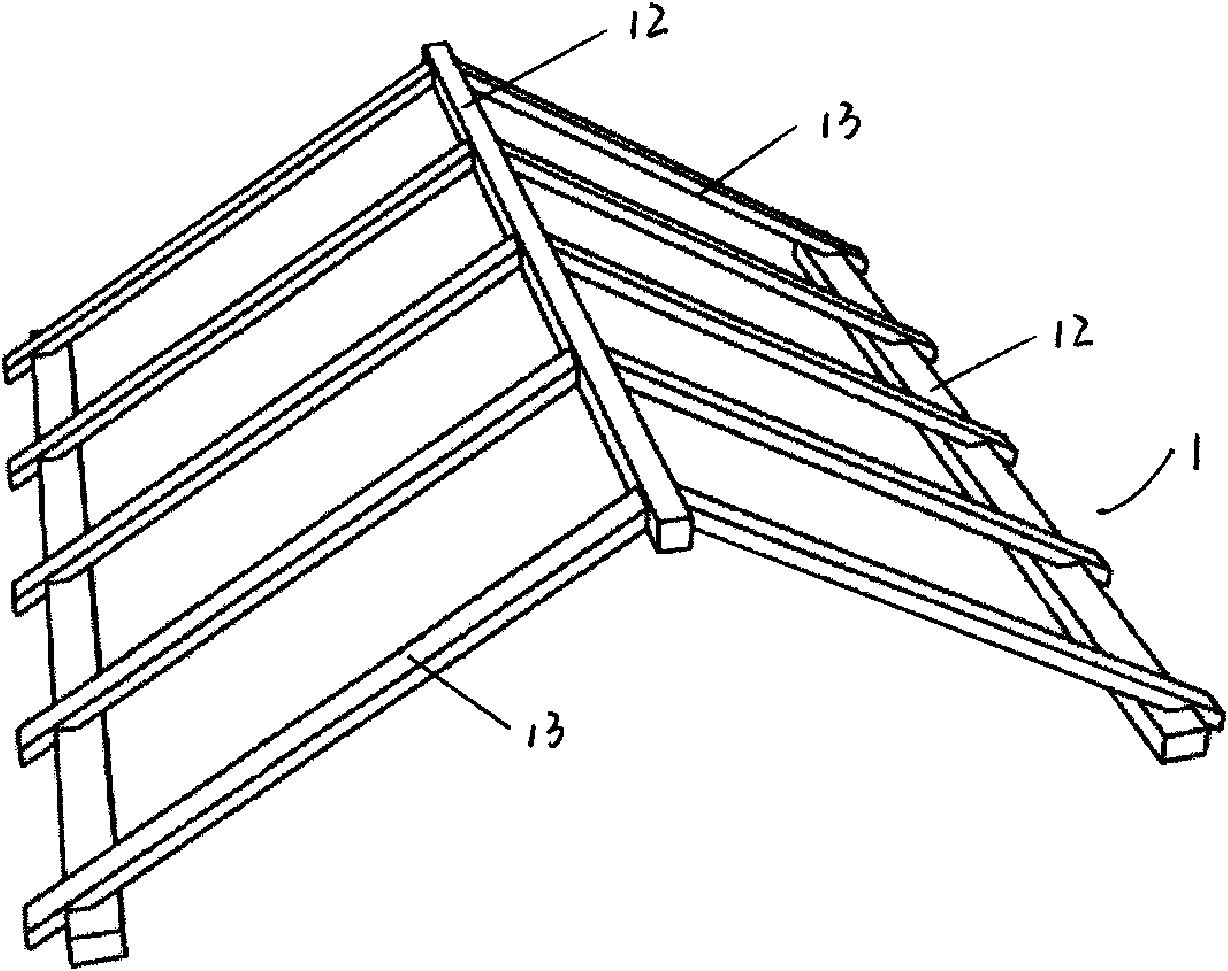

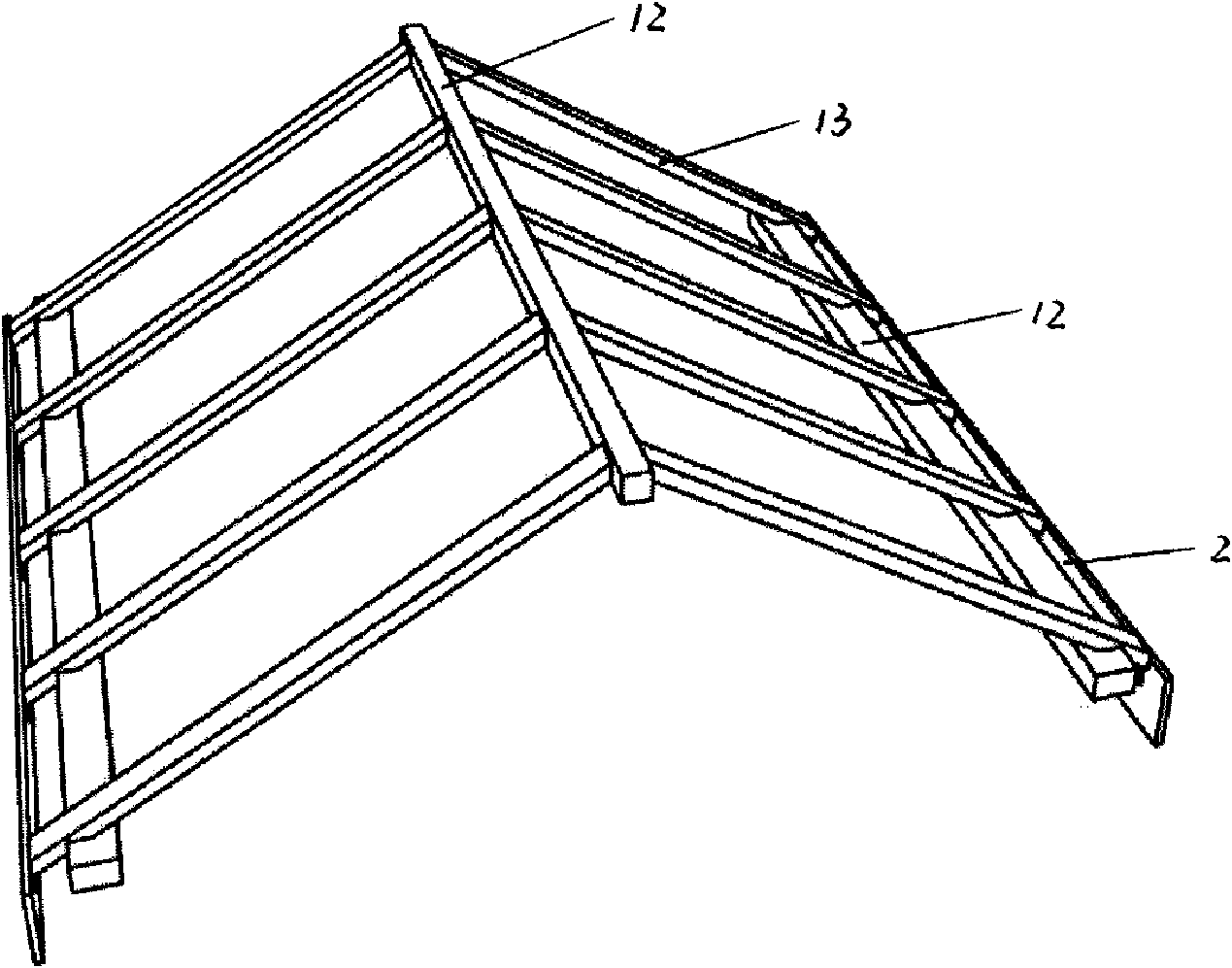

[0041] The present invention comprises roof frame 1, EPS board (polystyrene board) 3 and waterproof board 5, and the section of roof frame 1 is triangular, is made up of three transverse ribs 12 and many longitudinal ribs 13, and three transverse ribs 12 press The triangles are respectively arranged on three vertices, and a plurality of longitudinal ribs 13 are respectively arranged between the horizontal ribs at the highest point and the other two lower horizontal ribs; one end of the longitudinal ribs 13 is fixed at the highest horizontal On both sides of the ridge, the other end is fixed on the lower transverse ridge and extends outward for a certain distance. The extended distance can be determined according to the requirements of the design drawings. An EPS board 3 is arranged between two adjacent longitudinal ribs 13, and the upper surface of the EPS board is coplanar with the upper surface of the longitudinal ribs; a reflective film 4 is pasted on the EPS board 3 and the...

Embodiment 2

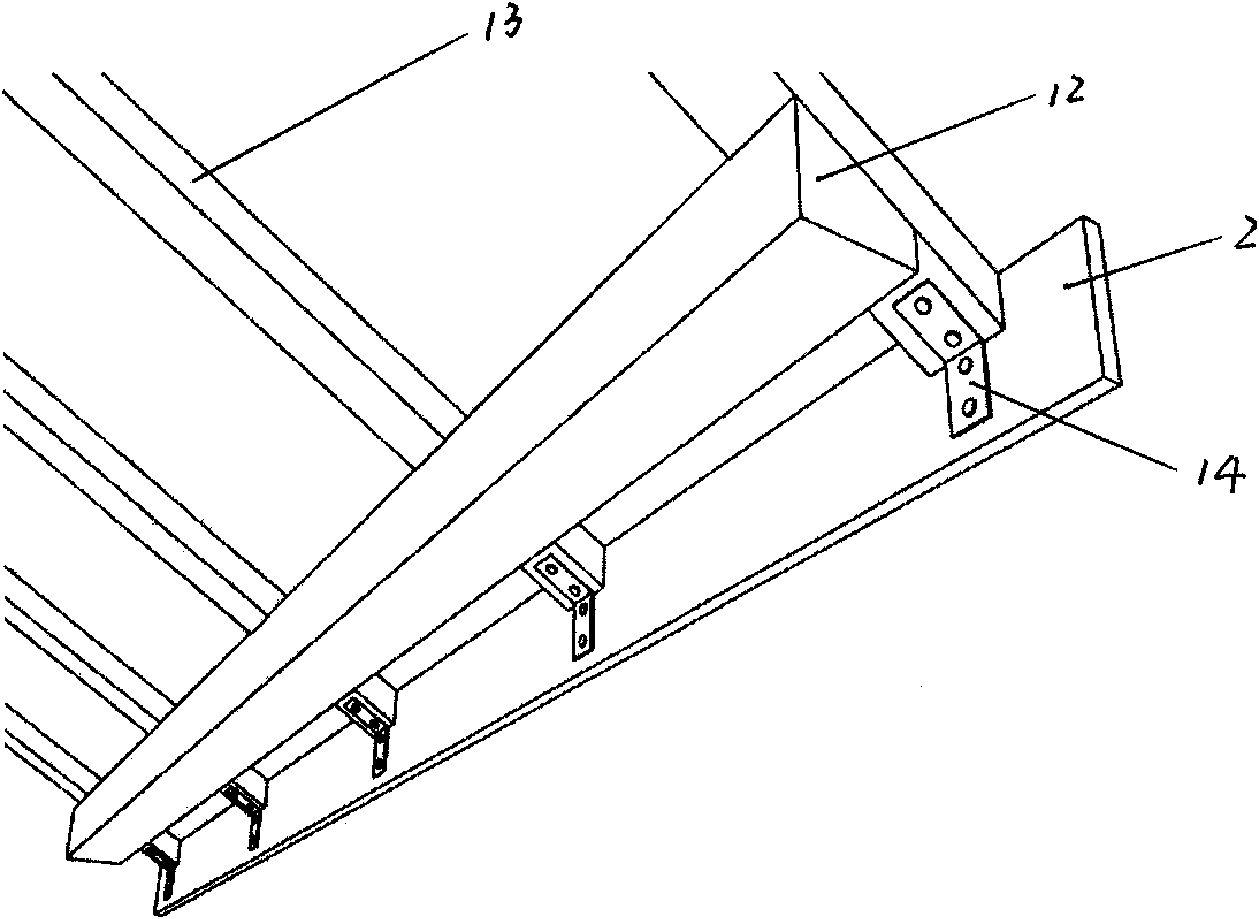

[0046] The difference between this embodiment and Embodiment 1 is that the thickness of the EPS board 3 is smaller than the thickness of the longitudinal ribs 13, and the upper surface of the EPS board installed between the longitudinal ribs is lower than the upper surface of the longitudinal ribs; The ribs 13 can be in the shape of "I" or square. When the longitudinal ribs 13 are in the shape of "I", the EPS board 3 is installed in the groove of the shape of "I"; A support beam may be arranged between the longitudinal ribs, and the EPS board is installed on the support beam. Since there is a height difference between the EPS board and the longitudinal rib, after the waterproof board is installed on the longitudinal rib, there will be a gap for air exhaust between the reflective film on each EPS board. In addition, on both sides near the top of the roof and above the EPS boards with reflective films, there are respectively added transverse ribs 12, which are also fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com