Prefabricated slab and fixed mounting structure thereof

A technology of prefabricated panels and mounting holes, which is applied in the field of building materials to achieve the effects of reducing cutting and waste, facilitating connection, and facilitating factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

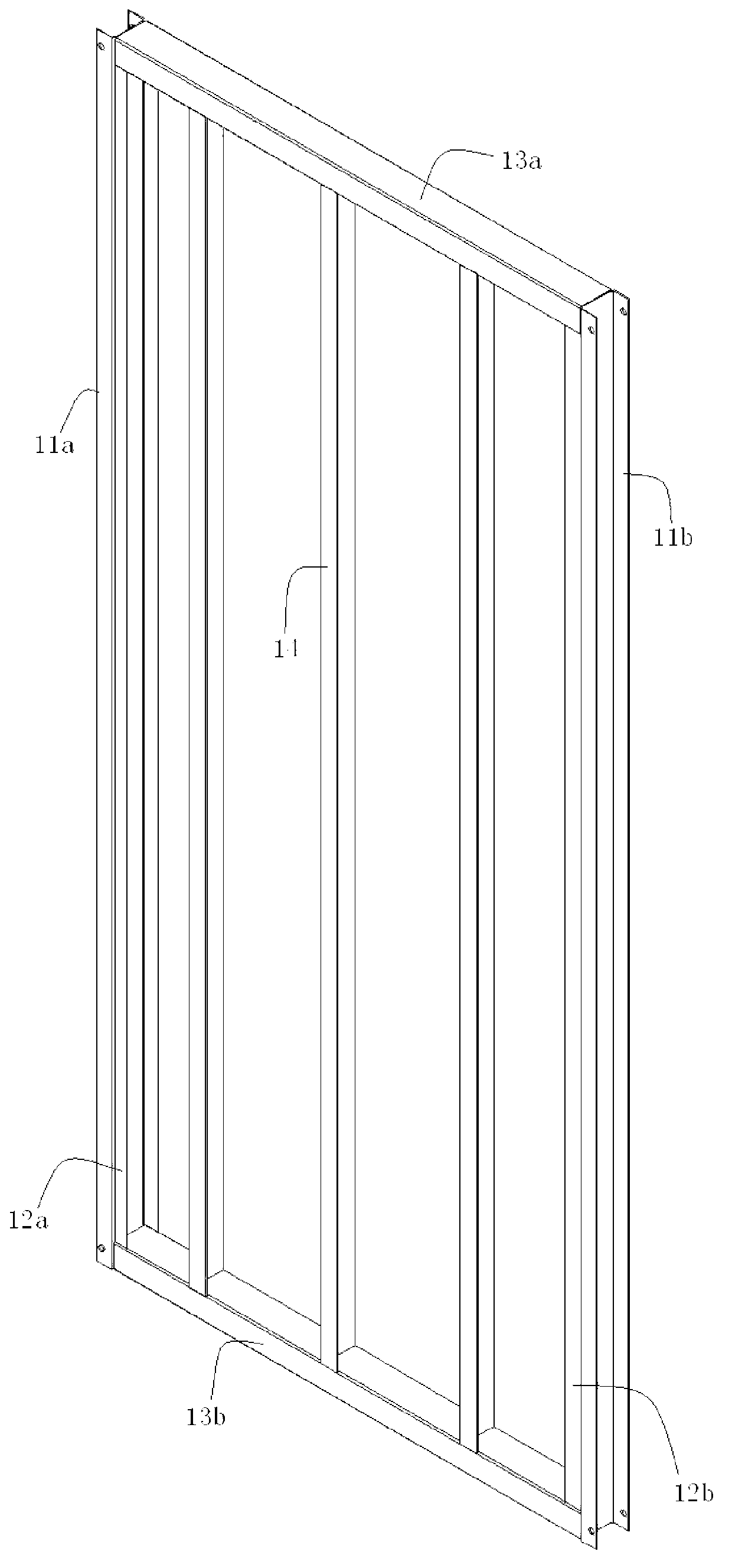

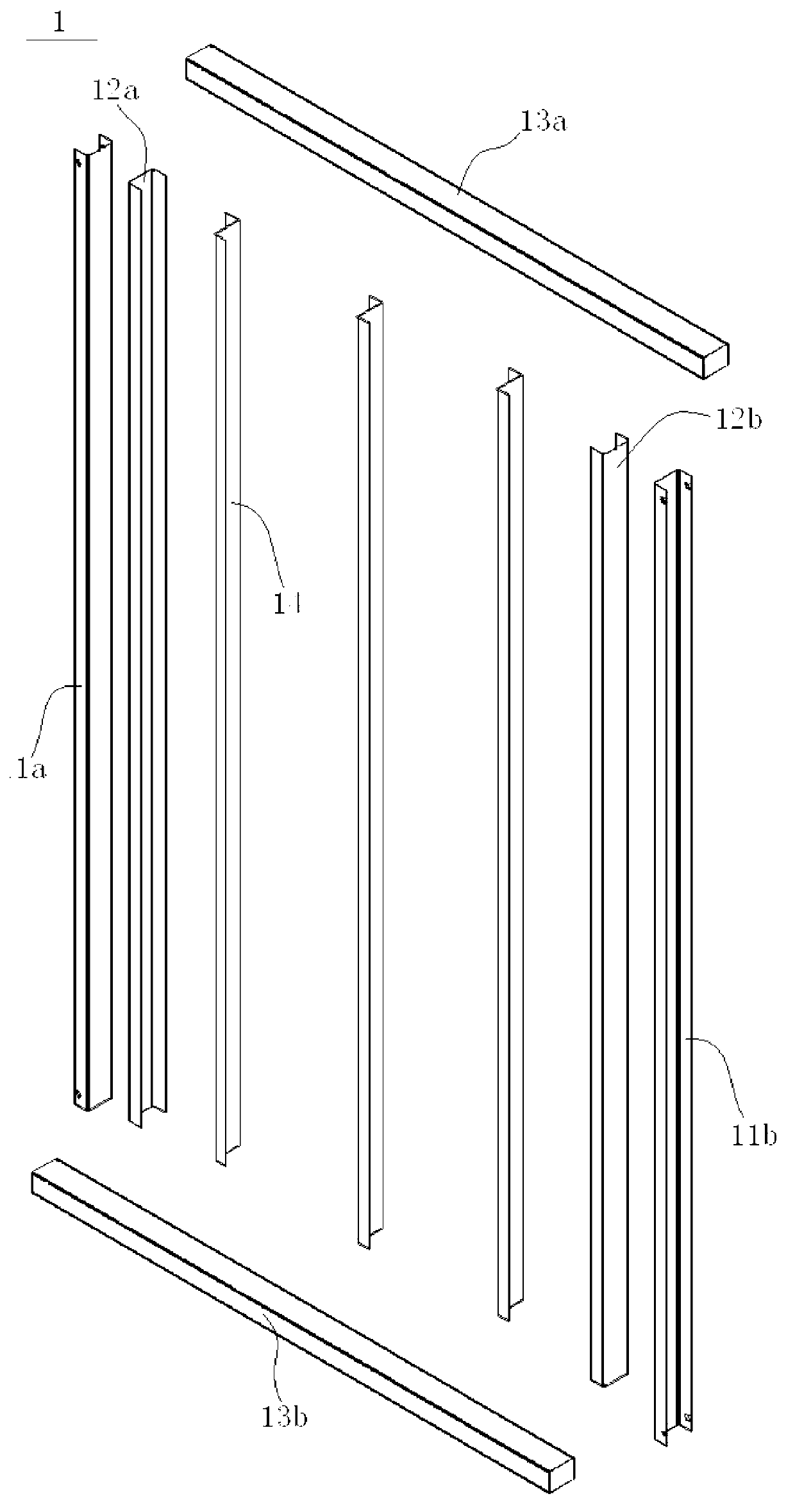

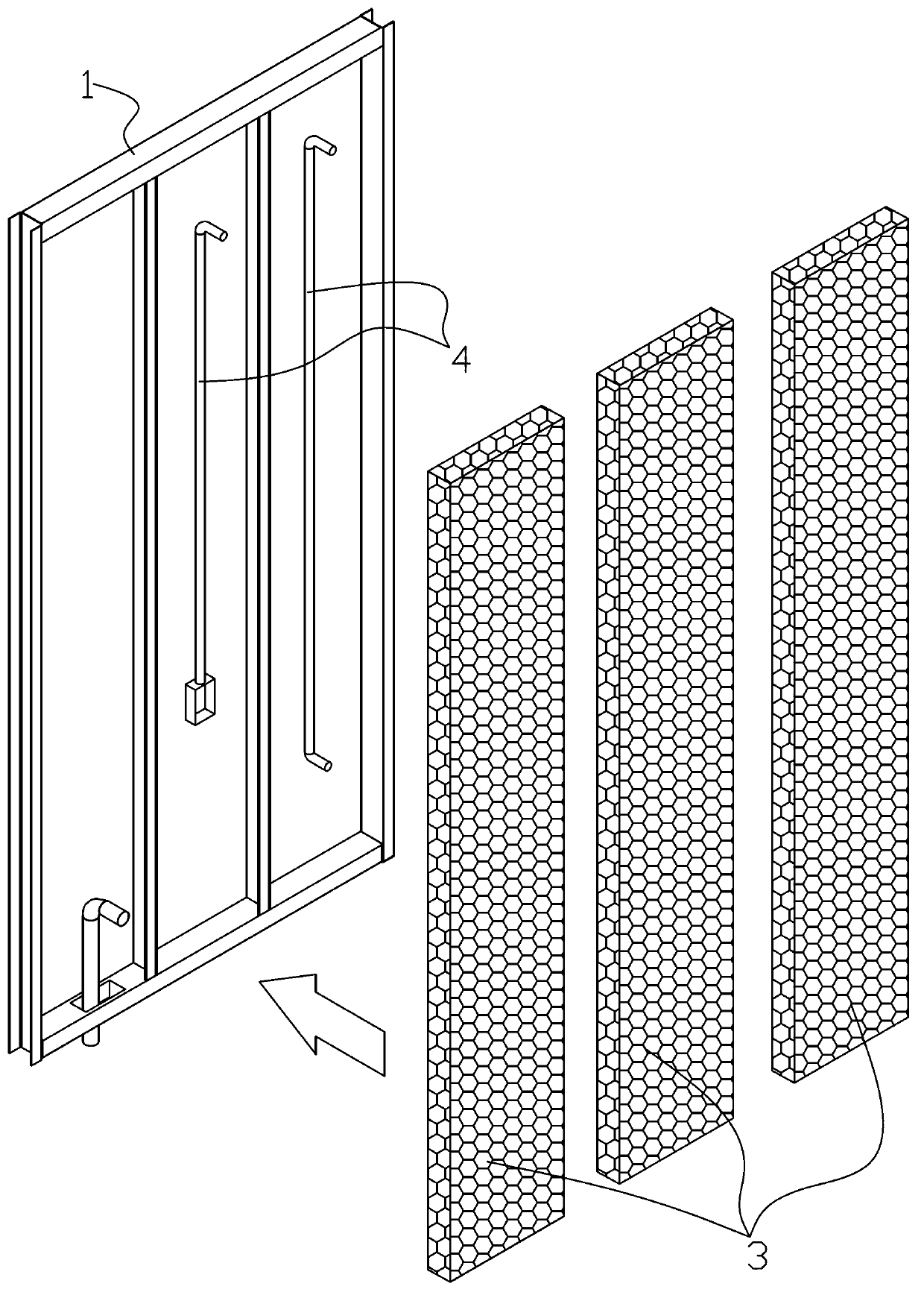

[0036] Such as Figures 1 to 7As shown, the prefabricated panel of the present invention includes a light steel frame 1 (or referred to as a light steel frame) and front and rear panels 2a, 2b, and the light steel frame 1 includes surrounding (can be surrounded by welding) together) form the left and right frames 11a, 11b and the upper and lower frames 13a, 13b of a square frame, the cross section of the left and right frames 11a, 11b is U-shaped, that is, the left and right frames 11a, 11b are U-shaped steel, , The U-shaped notches of the right frame 11a, 11b are respectively set towards the left and right, so that the prefabricated panel A can be connected with the structural components (especially the rigid structural components) for fixing the prefabricated panel through the U-shaped notches on the left and right sides. Insertion, the front and rear connecting arms of the left and right frames 11a, 11b (that is, the two opposite side arms of the U-shaped steel) are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com