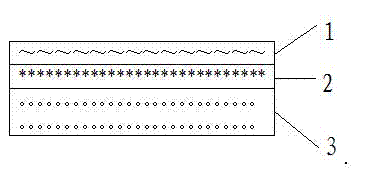

Flexible thermal-insulating decorative material for internal wall and method for producing flexible thermal-insulating decorative material

A decorative material and interior decoration technology, which is applied in the field of building materials, can solve problems such as waste, energy consumption of the internal environment, and lack of thermal insulation, and achieve simple construction, excellent flame retardant performance, and good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

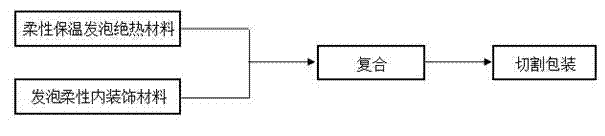

[0065] Production steps of flexible interior wall insulation and decoration materials:

[0066] (1) Flexible foam insulation layer: Disperse the raw materials through an 800rp / rotation strong disperser at room temperature for 30 minutes to obtain a uniform mixture. Mix the mixture at 100°C using a closed rubber mixer. Calendered into a 10mm sheet, foamed at 220°C to make a 15mm thermal insulation foam coil;

[0067] Among them, the raw material is soft PVC / NBR rubber and plastic foaming material, and the composition ratio is (by weight):

[0068] 60 parts of PVC powder;

[0069] 20 parts of rubber modifier;

[0070] 4 parts of stabilizer;

[0071] AC blowing agent 8 parts;

[0072] 70 parts of plasticizer;

[0073] Antimony oxide flame retardant 6 parts;

[0074] 1 part antifungal agent;

[0075] 30 parts of stuffing;

[0076] The PVC powder is a type 2 polyvinyl chloride resin produced by a suspension method; the rubber modifier is neoprene; the plasticizer is DOP; an...

Embodiment 2

[0080] Production steps of flexible interior wall insulation and decoration materials:

[0081] (1) Flexible foam insulation layer: Disperse the raw materials through a 1000rp / rotation strong disperser at room temperature for 20 minutes to obtain a uniform mixture. Mix the mixture at 80°C using a closed rubber mixer. Calendered into 8mm sheet, foamed at 240°C to make 11mm thermal insulation foam coil;

[0082] Among them, the raw material is soft PVC / NBR rubber and plastic foaming material, and the composition ratio is (by weight):

[0083] 80 parts of PVC powder;

[0084] 50 parts of rubber modifier;

[0085] 5 parts of stabilizer;

[0086] AC foaming agent 10 parts;

[0087] 60 parts of plasticizer;

[0088] Antimony oxide flame retardant 8 parts;

[0089] 3 parts antifungal agent;

[0090] Filling 60 parts;

[0091] The PVC powder is a type 3 polyvinyl chloride resin produced by a suspension method; the rubber modifier is NBR rubber; the plasticizer is DINP; and the...

Embodiment 3

[0095] Production steps of flexible interior wall insulation and decoration materials:

[0096] (1) Flexible foam insulation layer: Disperse the raw materials through a 1200rp / rotation strong disperser at room temperature for 15 minutes to obtain a uniform mixture. Mix the mixture at 120°C using a closed rubber mixer. Calendered into a 1mm sheet and foamed at 220°C to make a 4mm thermal insulation foam coil;

[0097] Among them, the raw material is soft PVC / NBR rubber and plastic foaming material, and the composition ratio is (by weight):

[0098] 50 parts of PVC powder;

[0099] 25 parts of rubber modifier;

[0100] 3 parts of stabilizer;

[0101] AC blowing agent 5 parts;

[0102] 20 parts of plasticizer;

[0103] Antimony oxide flame retardant 1 part;

[0104] Antifungal agent 0.1 part;

[0105] Filler None;

[0106] The PVC powder is a type 5 polyvinyl chloride resin produced by a suspension method; the rubber modifier is CPE rubber; the plasticizer is DEP; and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com