Continuous-casting and continuous-rolling integrating device and process

An integrated technology of continuous casting and rolling, applied in the direction of metal rolling, temperature control, etc., can solve the problems of inability to improve production efficiency, potential safety hazards, uncontrollable billet temperature, etc., to improve equipment utilization and production efficiency, The effect of improving production automation and improving metal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

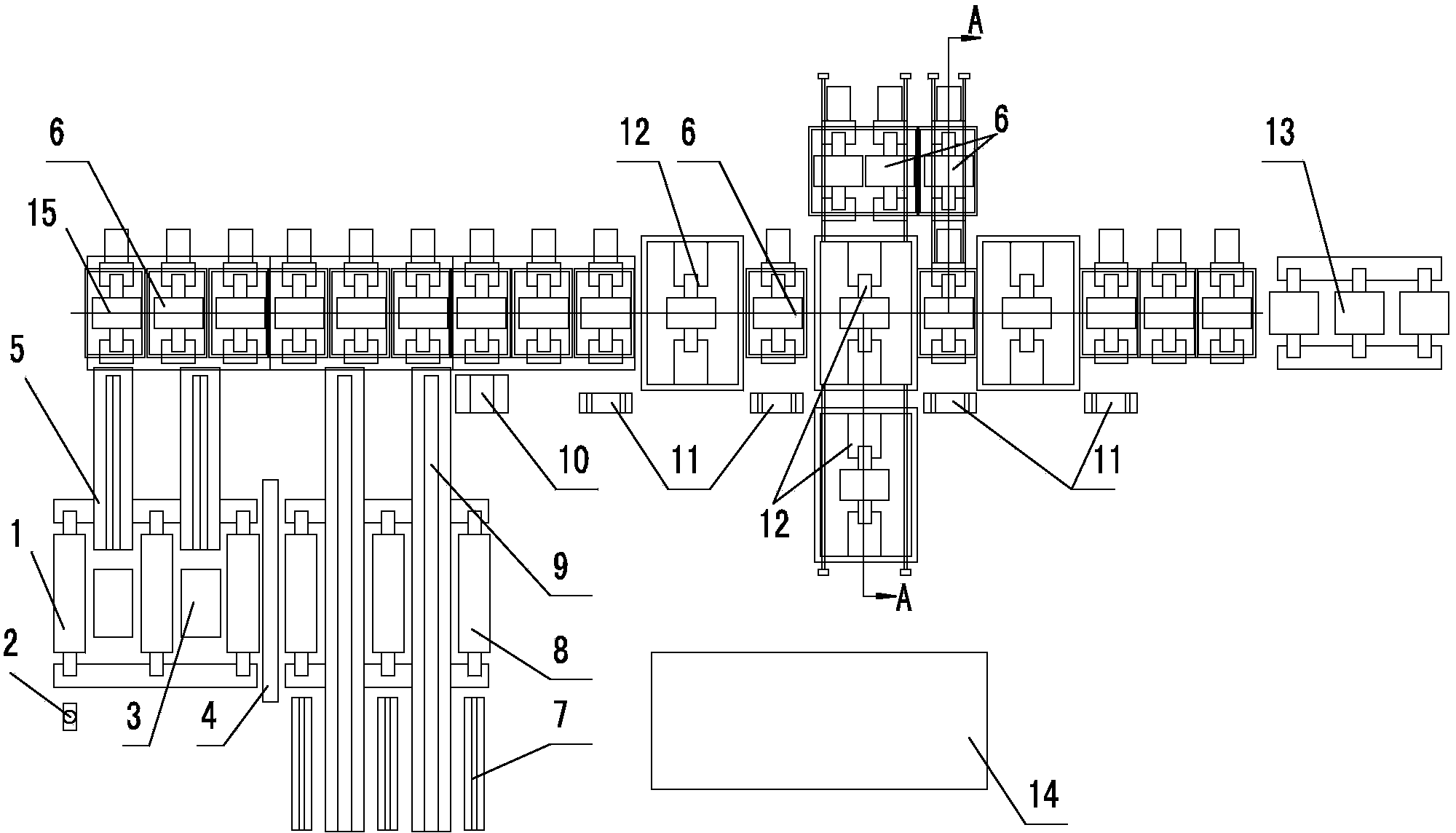

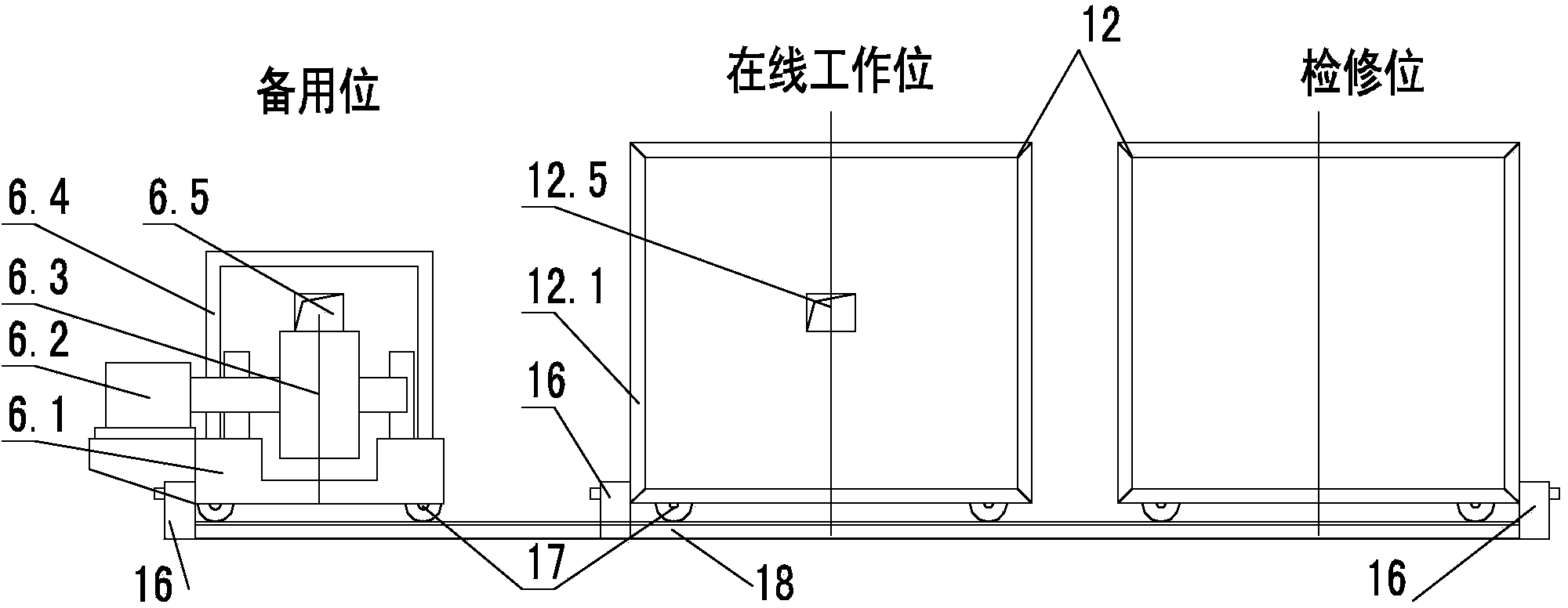

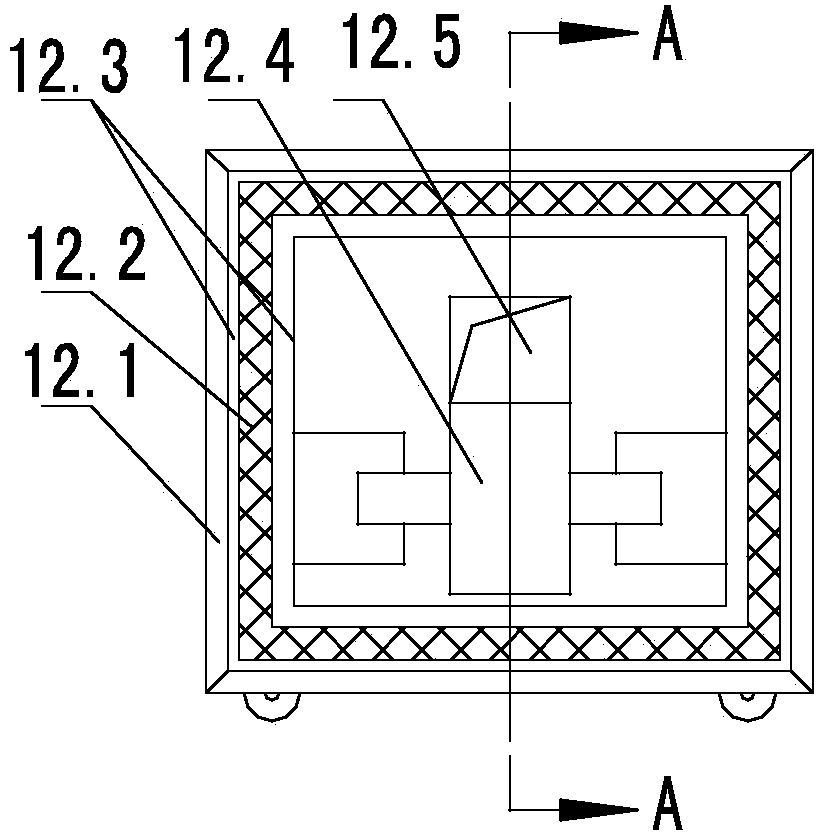

[0023] like Figure 1-4 As shown, a continuous casting and rolling integrated device implemented according to the present invention mainly includes a billet discharge roller table 1, which is characterized in that: an online weighing device 3 and a sizing detection device 2 are arranged in the billet discharge area of the billet discharge roller table 1 1. The blanking roller table 1 and the transitional roller table 8 are connected in a straight line, and a movable baffle 4 that can be automatically raised and lowered is set at the docking point; The roller table 6 is docked with the billet splitting device 5 with a thermal insulation device and can move the billet from the billet roller table 1 to the hot delivery roller table 6 through the billet splitting device 5; the transition roller table 8 (the billet roller The transitional cooling bed 7 is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com