Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

A technology for thermal insulation walls and wall structures, applied in thermal insulation, walls, building components, etc., can solve problems such as complex theoretical calculations, hidden dangers in permanent safety, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

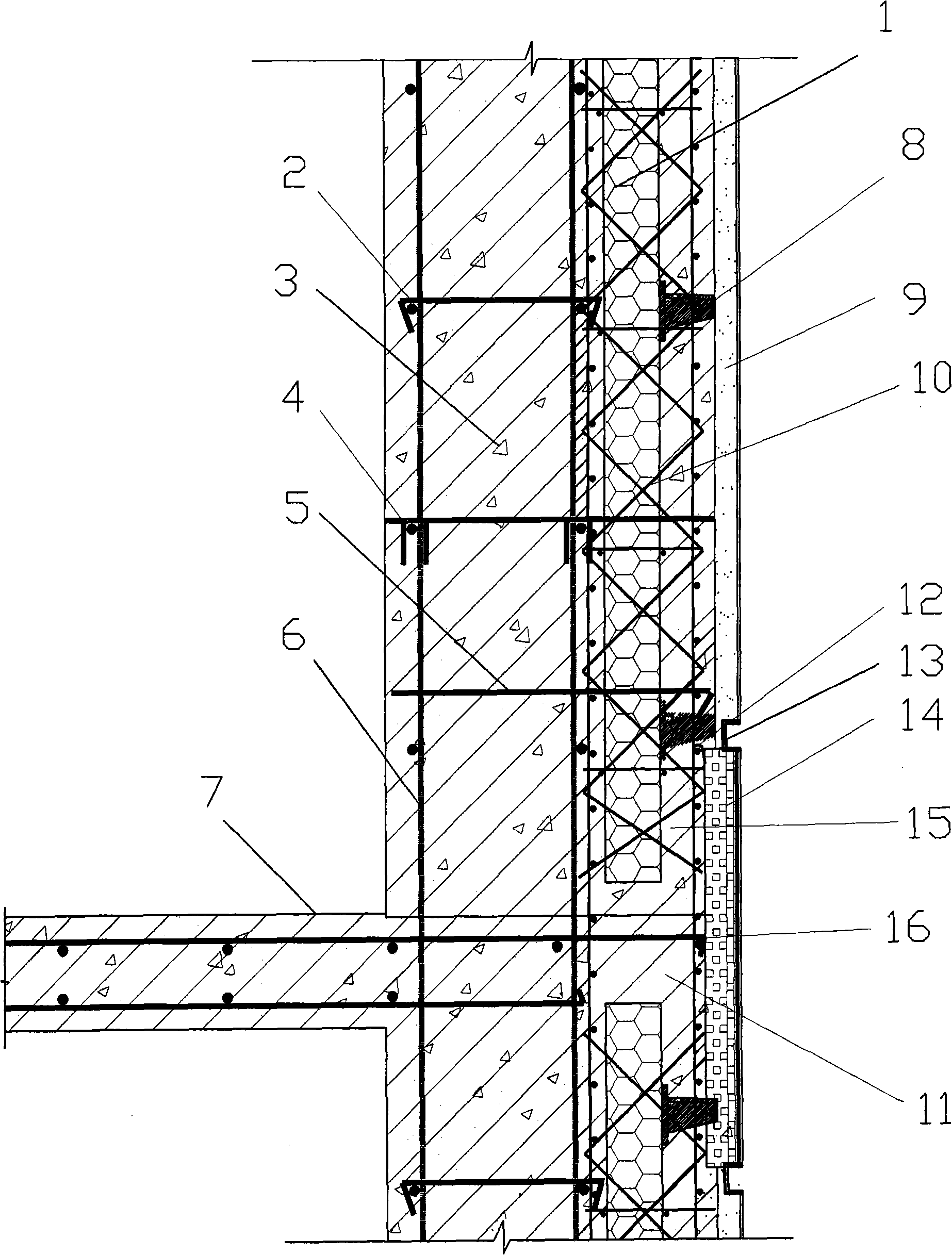

[0006] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] As shown in the accompanying drawings, the present invention includes a structural wall body 3 and the vertical steel bar 6 therein, and the vertical steel bar 6 in the wall is equipped with a transverse horizontal hook steel bar 2 perpendicular to it, a horizontal tie steel bar 5, a lateral support pull The reinforcement 4 is connected with the cantilevered corbel 11 of the floor to transmit the load of the concrete protective layer 15 on the outside of the wall, and the wall is connected with the outer extruded plastic insulation board 1 and the double-layer steel wire mesh bar 10 by tie knots. There is a decorative insulation layer 14 on the cantilevered corbel of the node floor outside the wall, an external decorative insulation layer and a decorative layer 9 on the outside of the wall components, and the concrete prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com