Flower-like structured CuS material as well as preparation method and application thereof

A flower-like structure, dye technology, applied in chemical instruments and methods, copper sulfide, water treatment of special compounds, etc., can solve the problems of difficult operation, tight supply chain, low selectivity, etc., to achieve high photocatalytic degradation efficiency, self- The effect of moderate assembly speed and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

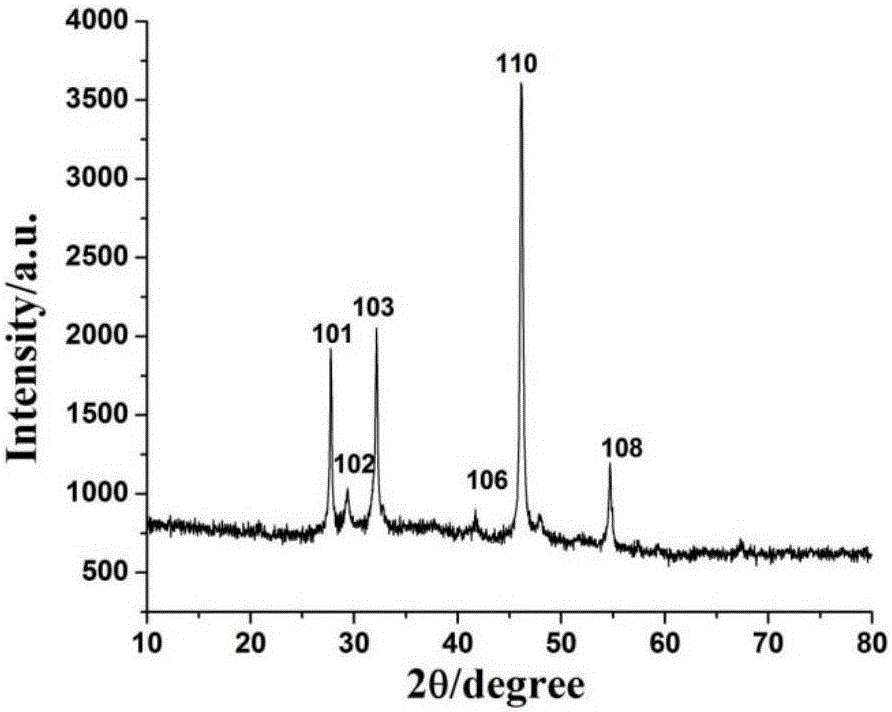

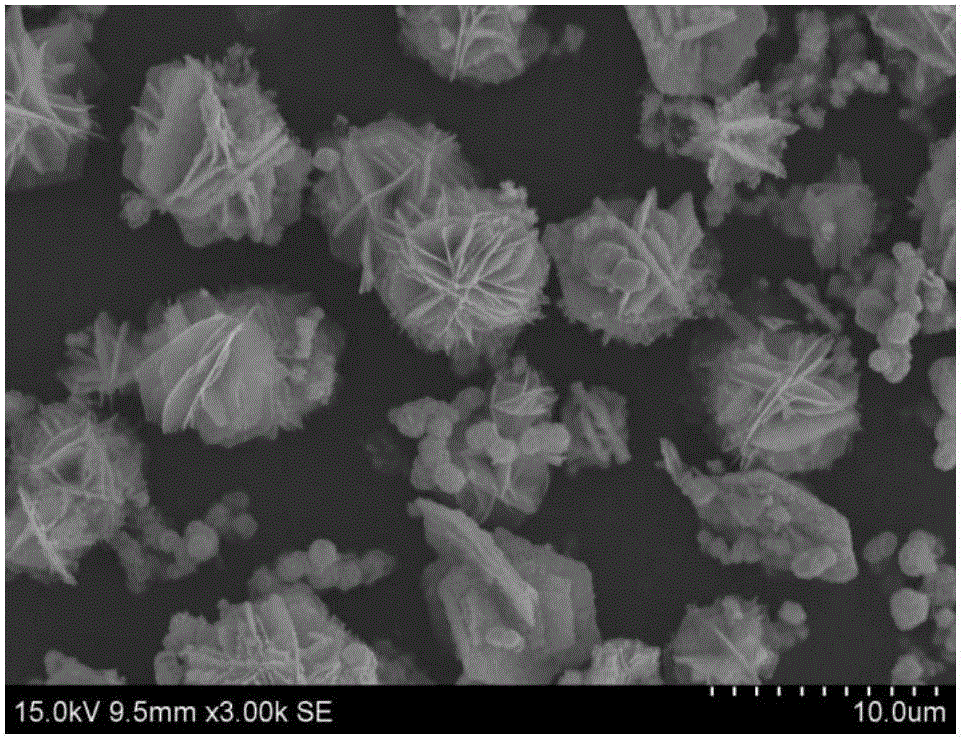

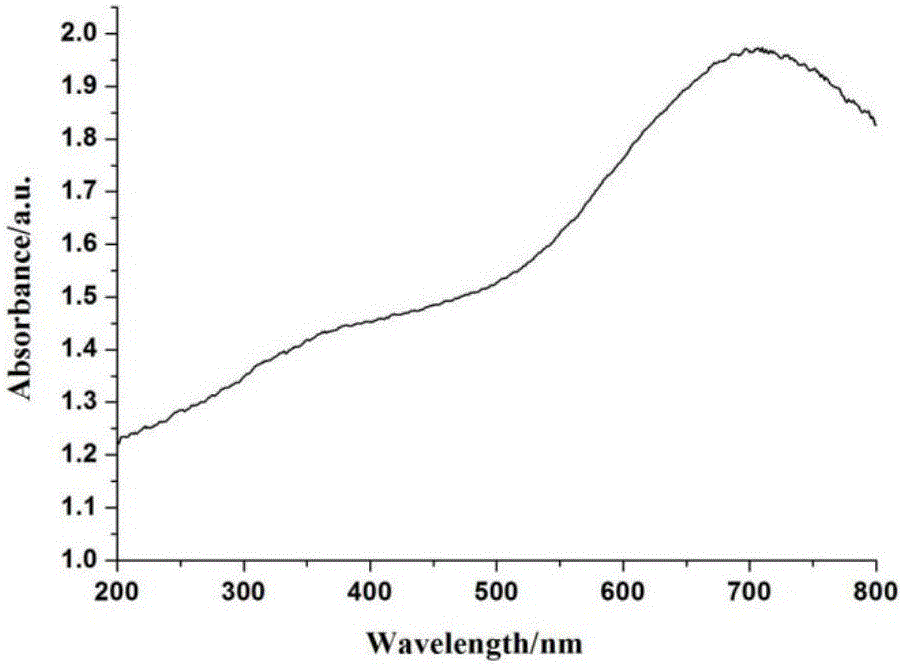

[0044] Add 1.7g of copper acetate and 100mL of 1-2 propylene glycol into a 250mL three-neck flask, raise the temperature to 120°C, and keep stirring for 20min to obtain a green solution. Under vigorous stirring, dissolve 3.04g of thioacetamide in 100mL of ethylene glycol solution, and slowly add the above solution, the solution changes from green to milky white, and finally turns into light yellow. Transfer the light yellow solution above to a 250mL polytetrafluoroethylene hydrothermal reaction kettle, seal it and place it in a constant temperature oven to heat at 170°C for 5h. After the reaction was finished, it was naturally cooled, and the product was washed several times with deionized water and absolute ethanol. Dry in a constant temperature vacuum oven at 50°C for 10 hours, and grind to obtain black copper sulfide powder. Its XRD is attached figure 1 , SEM see attached figure 2 , UV-Vis absorption spectrum see attached image 3 , Forbidden width, see attached Figu...

Embodiment 2

[0046] Add 1.7g of copper chloride and 200mL of 1-2 propylene glycol (PG) into a 250mL three-neck flask, raise the temperature to 120°C, and keep stirring for 20min to obtain a green solution. Under strong stirring, 3.04g of thiourea [(NH2)2CS,Tu] was dissolved in 100mL of ethylene glycol solution and slowly added to the above solution, the solution changed from green to milky white and finally light yellow. Transfer the light yellow solution above to a 250ml polytetrafluoroethylene hydrothermal reaction kettle, seal it and place it in a constant temperature oven to heat at 170°C for 5h. After the reaction was finished, it was naturally cooled, and the product was washed several times with deionized water and absolute ethanol. Dry it in a constant temperature vacuum oven at 50°C for 10 hours, and grind it to obtain black powder copper sulfide. The SEM is shown in the attached Figure 6 .

Embodiment 3

[0048] 1.7g copper chloride (CuCl 2 2H 2 (0) and 200mL ethylene glycol (EG) were added into a 250ml three-necked flask, the temperature was raised to 120°C, and the mixture was stirred continuously for 20min to obtain a green solution. Under strong stirring, 3.04g of thioacetamide (TAA) was dissolved in 100mL of ethylene glycol solution and slowly added to the above solution, the solution changed from green to milky white, and finally turned into light yellow. Transfer the light yellow solution above to a 250ml polytetrafluoroethylene hydrothermal reaction kettle, seal it and place it in a constant temperature oven to heat at 170°C for 5h. After the reaction was finished, it was naturally cooled, and the product was washed several times with deionized water and absolute ethanol. Dry in a constant temperature vacuum oven at 50°C for 10 hours, and grind to obtain black powder copper sulfide, see attached for SEM Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com