High efficiency composite flocculant, its preparation method and application

A flocculant and composite technology, applied in the direction of flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, etc., can solve the problem of inconspicuous decolorization effect, achieve excellent adsorption and decolorization ability, convenient use, and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Composite Inorganic Polymer Flocculant A

[0027] 1. Preparation of polyaluminium-iron flocculant

[0028] According to the ratio of 1:0.7, take 30 grams of aluminum chloride and 21 grams of ferric sulfate respectively, put them in the reaction bottle, add 400 mL of distilled water, reflux and stir at 50 ° C ~ 60 ° C, and the pH value is 2 ~ 3 for 0.5 ~ 1 Hour.

[0029] 2. Preparation of coagulant aid

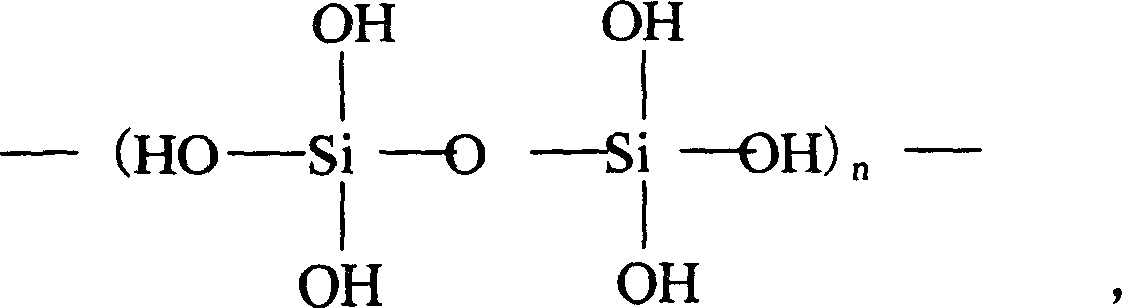

[0030] Dissolve 20 grams of sodium silicate and 10 grams of silicon oxide in 100 ml of distilled water, adjust the pH to 3-4 with sulfuric acid or hydrochloric acid, reflux and stir at 50-60°C for 30-45 minutes to obtain the coagulation aid . (n=8).

[0031] 3. Polymerized aluminum-iron flocculant reacts with coagulant aid Z to prepare flocculant A

[0032] Put the synthesized polyaluminium-iron in a reaction bottle, and slowly add 0.9 g of coagulation aid (inorganic polymer compound n=8) under the conditions of 40°C-50°C and pH=3-4...

Embodiment 2

[0033] Example 2 Preparation of composite polymer flocculant B

[0034]1. Preparation of polyaluminium-iron flocculant

[0035] According to the ratio of 1:0.7, take 20 grams of aluminum chloride and 14 grams of ferric sulfate respectively, put them in the reaction bottle, add 270 mL of distilled water, and reflux and stir the reaction at 50 ° C ~ 60 ° C and the pH value of 2 ~ 3 for 0.5 ~ 1 Hour.

[0036] 2. Polymerized aluminum iron flocculant and coagulant aid dodecyl dimethyl tertiary amine compound to form flocculant B

[0037] Put the synthesized polyaluminium-iron in a reaction bottle, and slowly add 20 grams of coagulant aid dodecyl dimethyl tertiary amine under the conditions of 40°C-50°C and pH=3-4, and stir under reflux for 1.5- 2 hours. After the compound is completed, the light yellow compound flocculant B is obtained.

Embodiment 3

[0038] Example 3 Preparation of composite inorganic-organic polymer flocculant C

[0039] 1. Preparation of composite inorganic polymer flocculant A

[0040] Put 34 grams of polyaluminium-iron in a reaction bottle, add 270 mL of distilled water, and slowly add 2 grams of coagulation aid (inorganic polymer compound n=8) at 40 ° C to 50 ° C and pH = 3 to 4 , reflux and stir for 1 to 1.5 hours. After the reaction is completed, a brown-yellow transparent composite flocculant A is obtained.

[0041] 2. Flocculant A and dodecyl dimethyl tertiary amine compound to form flocculant C

[0042] Put the synthesized flocculant A in a reaction flask, slowly add 20 grams of dodecyldimethyl tertiary amine under the condition of 50-60°C, and stir under reflux for 1.5-2 hours. The brown-yellow composite flocculant C can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com