Ferrum-based amorphous alloy strip for treating printing and dyeing wastewater and preparation method thereof

An iron-based amorphous alloy, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, reduced water/sewage treatment and other directions, can solve problems such as poor treatment effect, poor reusability, and many treatment conditions, and achieve low production costs. , the effect of easy industrialization and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

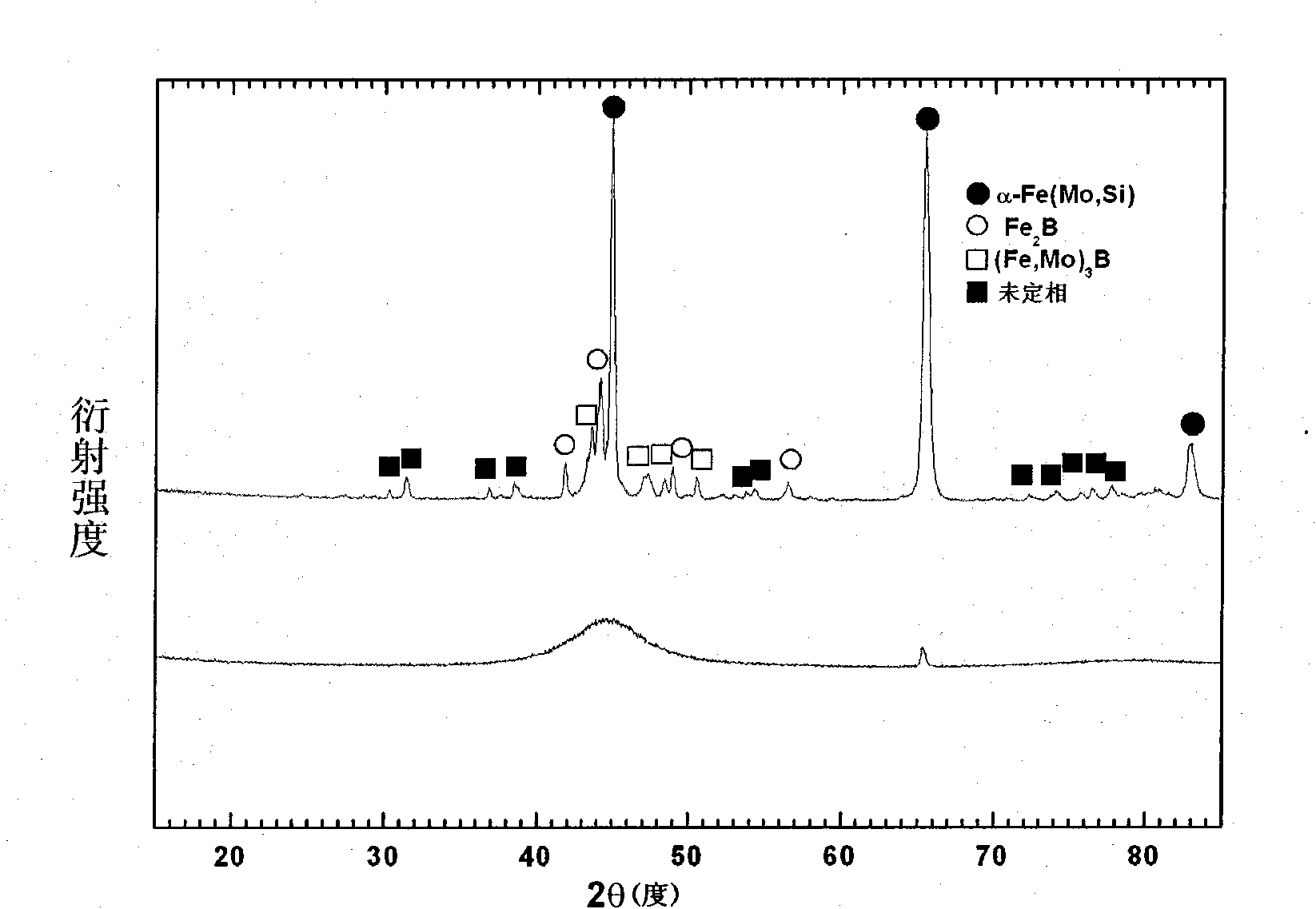

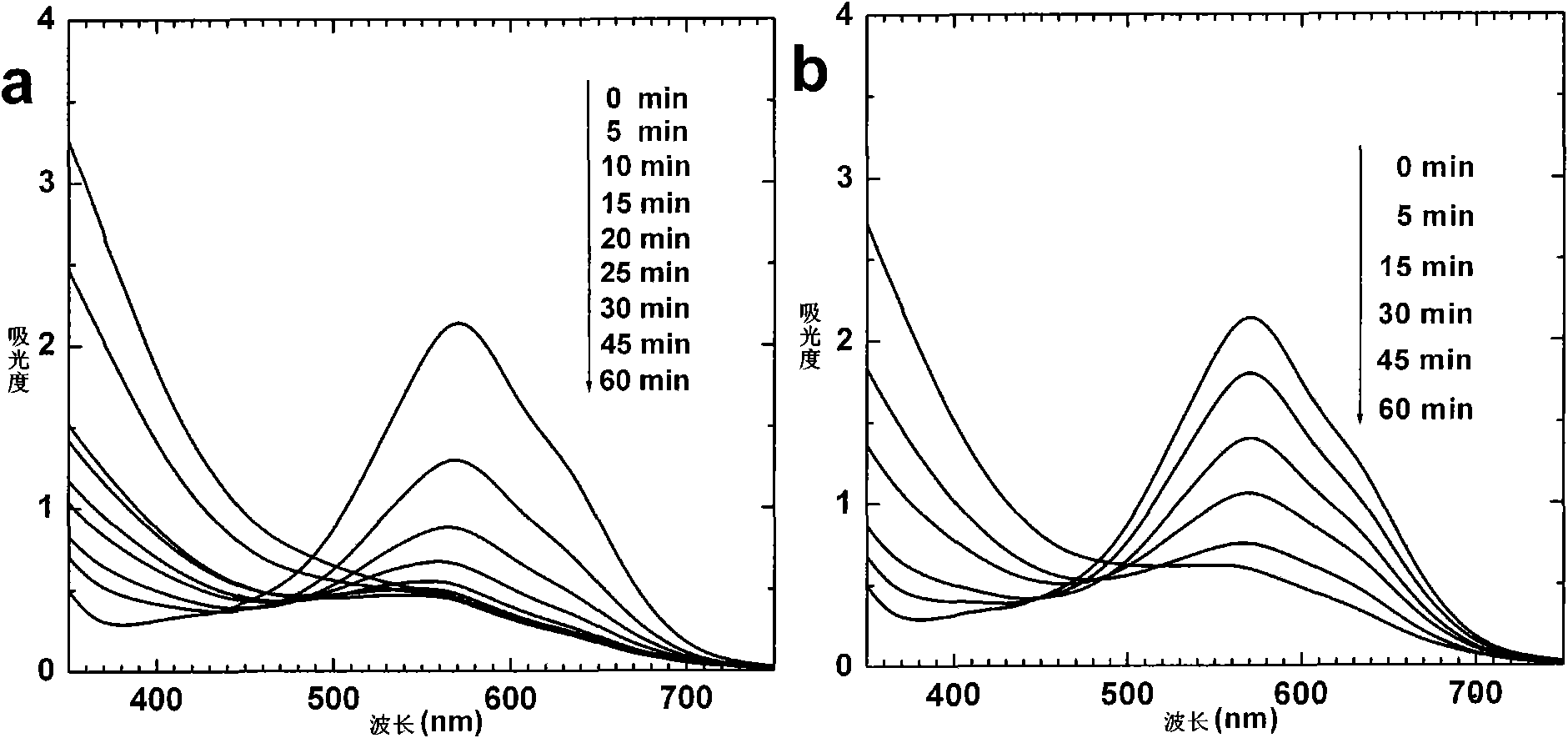

[0028] The following (Fe 0.99 Mo 0.01 ) 78 Si 9 B 13 Amorphous alloy strips are used as an example to illustrate the implementation of the method, and by combining with crystallized (Fe 0.99 Mo 0.01 ) 78 Si 9 B 13 The comparison of the strips is used to illustrate the decolorization effect of the material, and the feasibility of reusing the amorphous strips for decolorization is illustrated through related diagrams.

[0029] 1. According to the technical scheme mentioned above, for the atomic percentage composition of the alloy (Fe 0.99 Mo 0.01 ) 78 Si 9 B 13 As far as it is concerned, it is a very common component with a strong ability to form amorphous strips. The production technology is relatively mature and has been industrialized. Wherein the atomic percentage of the iron element is about 78%, which meets the appropriate composition range required in the technical proposal.

[0030] 2. Using Fe, Mo, Si, Fe 80 B 20 (wt.%) for smelting. Calculate the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com