Detection box used for detecting light transmittance of printing and dyeing wastewater

A technology for printing and dyeing wastewater and light transmittance, which is applied in the preparation of test samples, transmittance measurement, settling tanks, etc. It can solve problems such as nonlinearity, deviation between pH meter measured value and actual value, and extremely high control accuracy. Achieve the effect of low cost, good separation effect and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

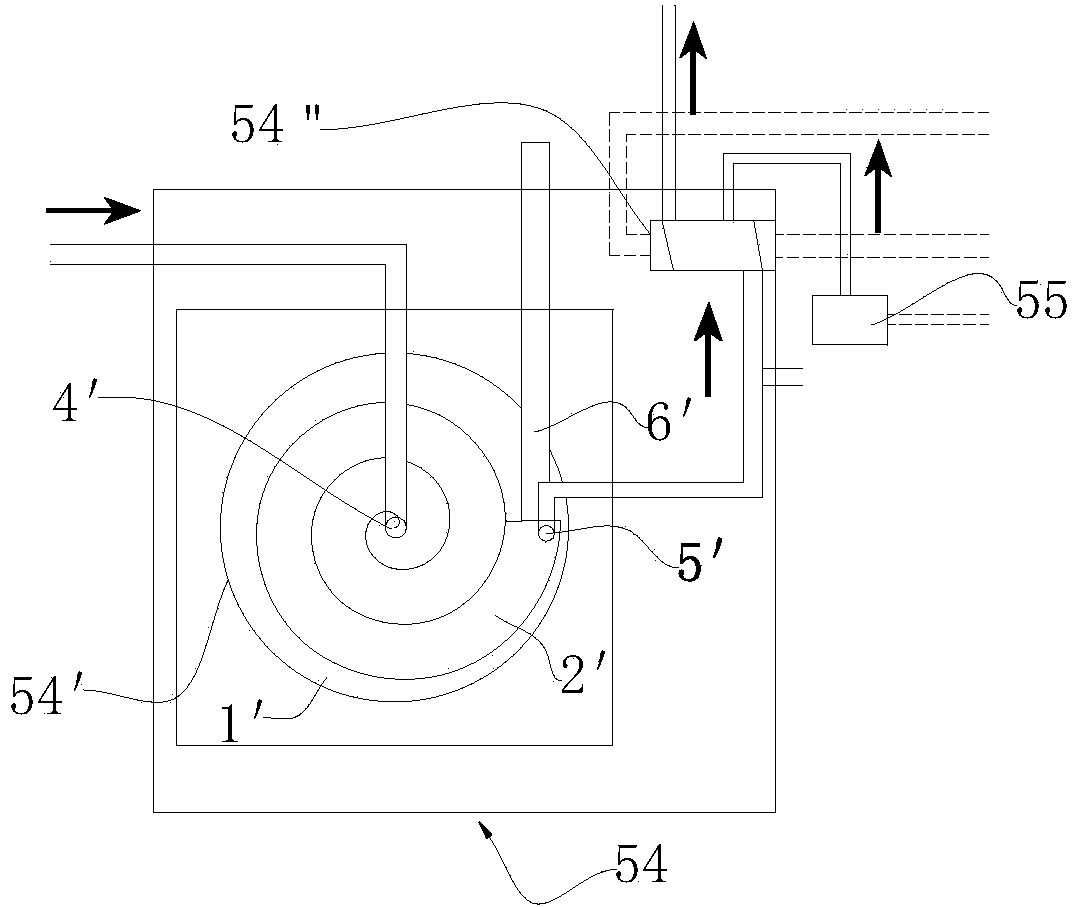

[0018] Such as figure 1 The detection box for detecting the light transmittance of printing and dyeing wastewater is shown, the detection box includes a box body, a settling device 54' connected in sequence to the sampling water inlet pipe 51, and a light detection device 54 for detecting the light transmittance of the printing and dyeing wastewater supernatant ", the sedimentation device 54' and the light detection device 54" are all in the box. The box body is provided with an input end for connecting the printing and dyeing wastewater sampling inlet pipe, a first output end for connecting the printing and dyeing wastewater sampling outlet pipe and a second output end for discharging sediment.

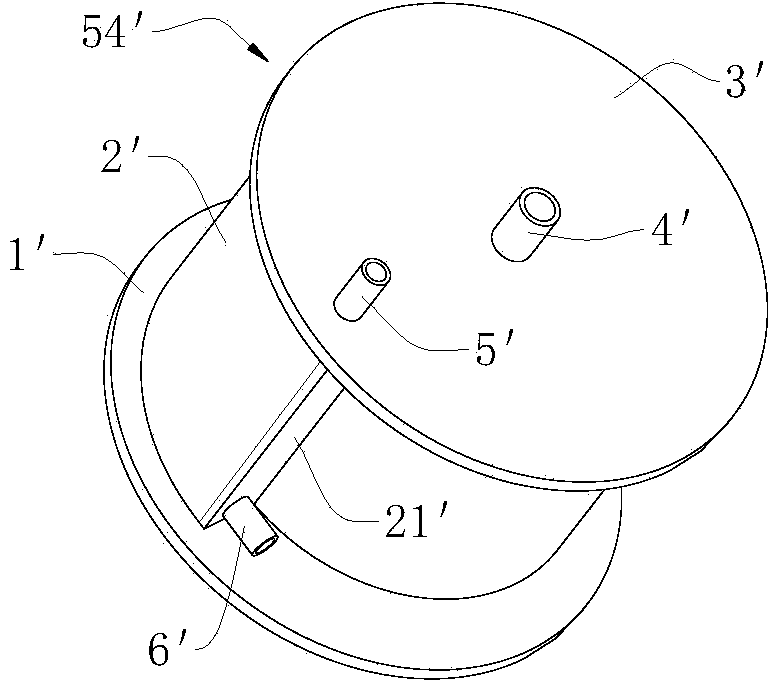

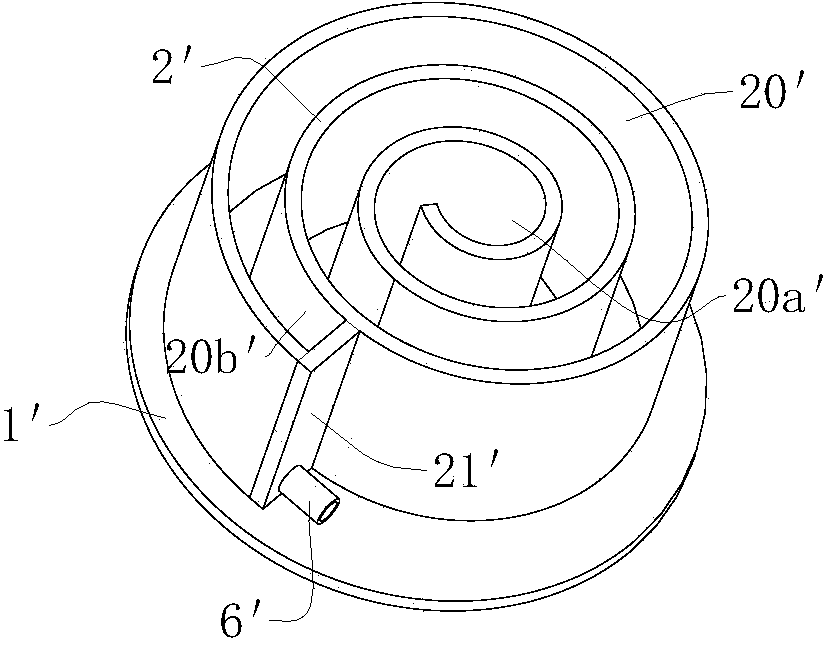

[0019] see figure 1 , figure 2 with image 3 As shown, the role of the settling device 54' is to quickly settle the solids in the sewage to separate the sewage supernatant, which is convenient for the optical detection device 54" used to detect the light transmittance of the prin...

Embodiment 2

[0023] The difference between this embodiment and embodiment 1 is that this embodiment adopts another kind of settling device, such as Figure 5 As shown, the settling device consists of a rectangular box 10' and a plurality of baffles 20' interlaced and fixed on the inner walls of the two sides of the rectangular box 10'. One end of the rectangular box 10' is provided with a water inlet pipe 40'. The rectangular box The bottom of the other end of the 10' is provided with a sedimentation outlet 60', and a supernatant outlet 50' is opened on the top wall near the other end of the rectangular box 10', and the supernatant outlet 50' is connected to the The printing and dyeing wastewater inlet pipe 1 ″ in the optical detection device 54 ″ for the light transmittance of the printing and dyeing wastewater supernatant. The rest are repeated in Example 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com