Multifunctional filter element structure

A multi-functional, filter element technology, applied in filtration and separation, sterilization/microdynamic water/sewage treatment, added substance water/sewage treatment, etc. To achieve the effect of increasing the surface area and extending the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

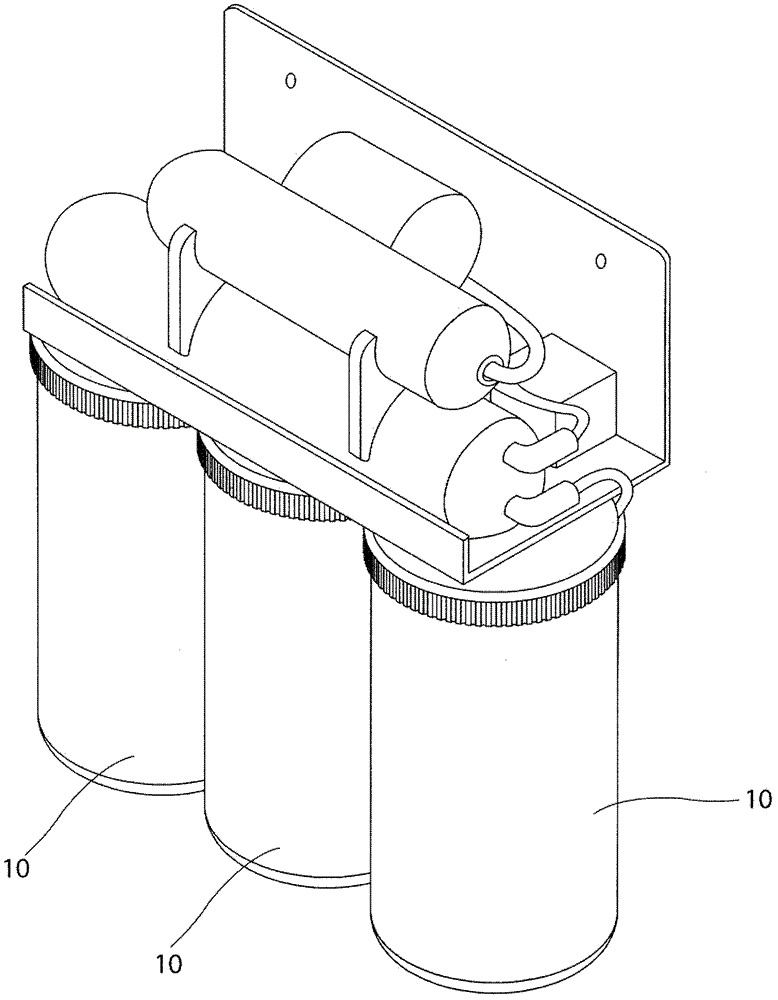

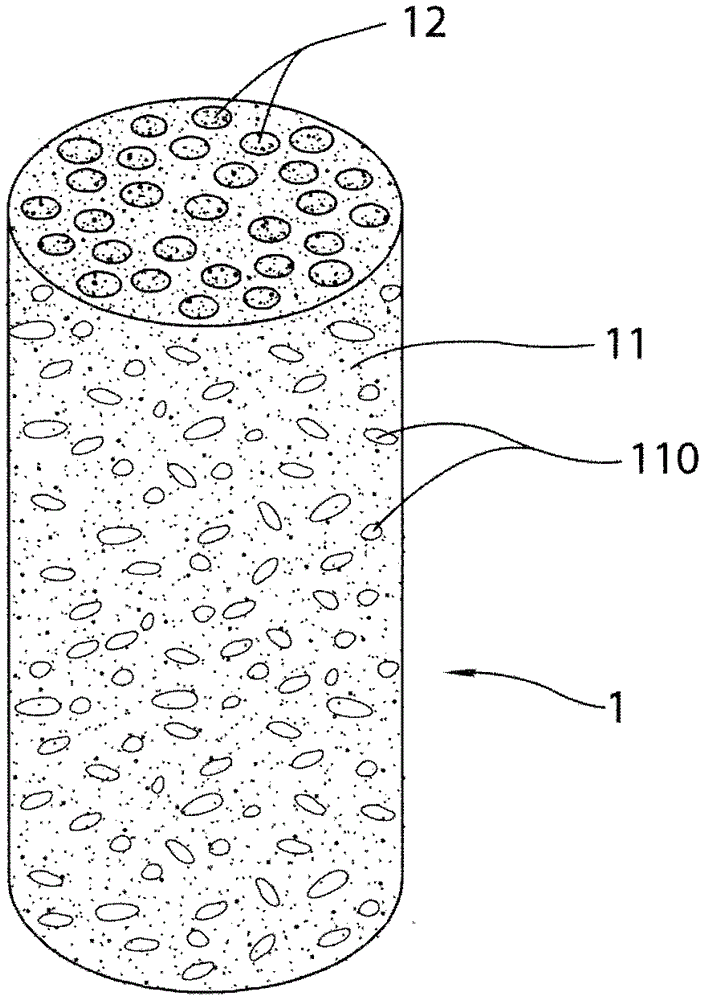

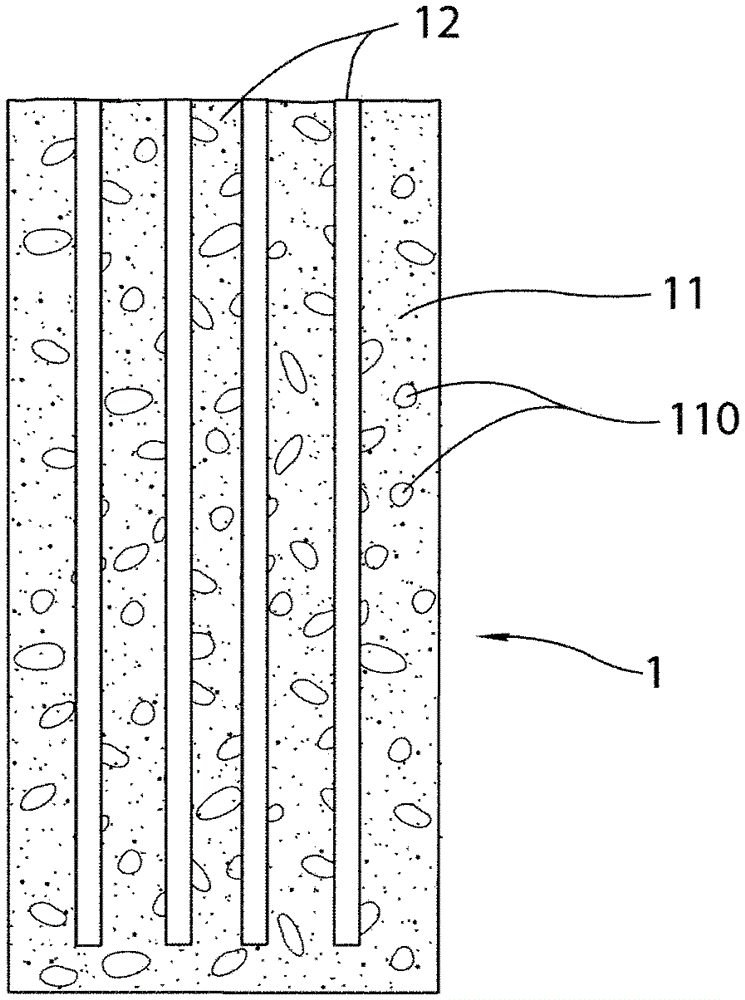

[0015] First, see figure 2 As shown, it is a three-dimensional appearance diagram of the present invention. The filter element 1 is made by extruding oxide crystals 11 to form a high-density cylindrical filter element shape, and the oxide crystals 11 are extruded with each other to form numerous fine particles. slit 110, and the filter element 1 is provided with a plurality of columnar holes 12 from the upper end face downward, which do not penetrate the filter element 1, so that the bottom of the filter element 1 remains closed (see image 3 As shown), after the raw water enters the columnar hole 12 of the filter element 1, it will not quickly flow out of the filter element 1 from the columnar hole 12, but will seep out from the gap 110 where the oxide crystals 11 are squeezed, so the raw water will flow to the oxide crystals. Permeate in all directions, keep the raw water staying in the filter element 1 for a long time, and increase the surface area in contact with the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com