Preparation method of supported metal catalyst

A metal catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve problems such as aggregation and affecting catalyst effect, and achieve operational controllability High, efficient catalytic effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

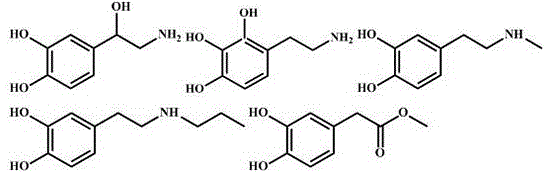

[0031]Dissolve 1g of montmorillonite in water to prepare an aqueous solution with a concentration of 1.0%. After ultrasonication for 2 hours, add 0.125g of DOPA. After DOPA is completely dissolved, add silver nitrate containing 0.125g of silver, react for 12 hours, and centrifuge to prepare the modified Nano-silver particles loaded on montmorillonite. Wherein, the mass ratio of nano-silver is 10.0%, the particle size is 5-100nm, and the mass ratio of montmorillonite to montmorillonite-loaded nano-silver particles is 80.0%. The mass ratio of DOPA in the montmorillonite-loaded silver nanoparticles was 10.0%.

Embodiment 2-6

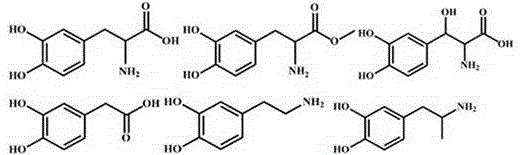

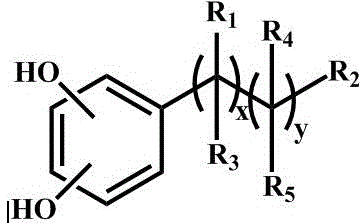

[0033] Dissolve 1g of montmorillonite in water to prepare an aqueous solution with a concentration of 1.0%. After ultrasonication for 2 hours, add 0.011g of 3,4-dihydroxybenzylamine or 3,4-dihydroxybenzaldehyde or 3,4-dihydroxy Phenylacetaldehyde or 3,4-dihydroxybenzoic acid or 3,4-dihydroxyphenylacetic acid was added with chloroauric acid containing 0.1 g of gold, reacted for 12 hours, and centrifuged to prepare modified montmorillonite loaded nano silver particles. Wherein, the mass ratio of nano-gold is 9.0%, the particle size is 5-100nm, and the mass ratio of montmorillonite to montmorillonite-loaded nano-gold particles is 90.0%. The mass ratio of dopamine derivatives in the montmorillonite-loaded gold nanoparticles was 1.0%.

Embodiment 7-13

[0035] Dissolve 1g of montmorillonite in water to prepare an aqueous solution with a concentration of 1.0%. After ultrasonication for 2 hours, add 0.011g of 3,4-dihydroxybenzylamine or 3,4-dihydroxybenzaldehyde or 3,4-dihydroxy Phenylacetaldehyde or 3,4-dihydroxybenzoic acid or 3,4-dihydroxyphenylacetic acid with acetic acid-sodium acetate buffer or phosphate buffer or citric acid-sodium citrate buffer or disodium hydrogen phosphate-lemon Acid buffer solution or phthalic acid-hydrochloric acid buffer solution or boric acid-borax buffer solution or sodium carbonate-sodium bicarbonate buffer solution buffer solution to adjust the pH value, add silver nitrate containing 0.25g of silver, react for 1 hour, centrifuge and wash to prepare improved Nano-silver particles loaded on montmorillonite. Wherein, the mass ratio of nano-silver is 20%, the particle size is 5-100nm, and the mass ratio of montmorillonite to montmorillonite-loaded nano-silver particles is 79.0%. The mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com