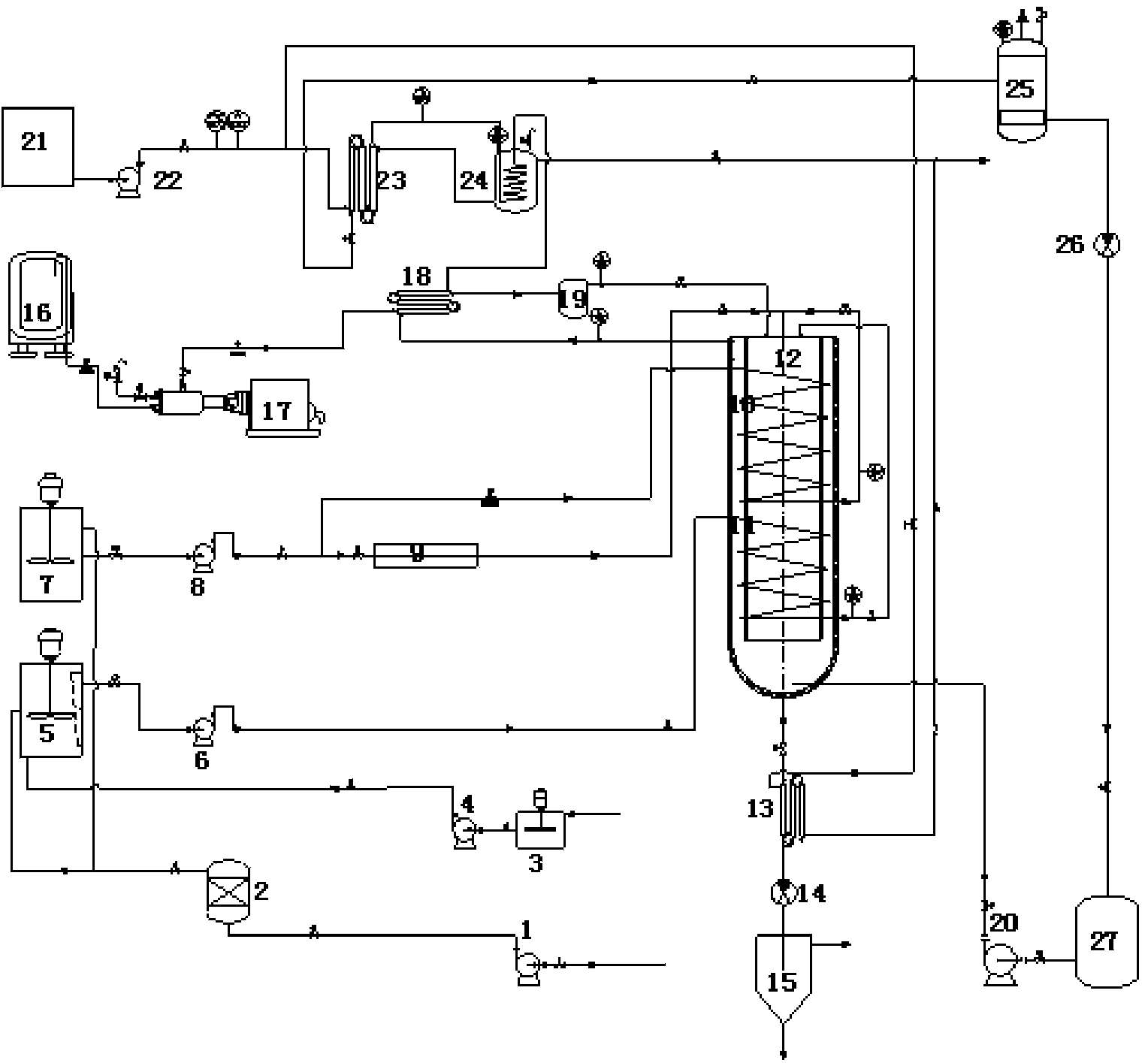

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

A technology for supercritical water oxidation and printing and dyeing wastewater, which is applied in the fields of oxidation treatment of sludge, textile industry wastewater treatment, oxidized water/sewage treatment, etc. It can solve the problems of strong pollution, large consumption of power electrode materials, and difficulty in discharge standards. Achieve the effects of reducing equipment investment and operating costs, reducing system equipment costs, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 500t / d of printing and dyeing wastewater enters the nanofiltration membrane concentration module 2, and after being concentrated five times, 100t / d of the concentrated solution is further treated, and the other 400t / d of purified water is reused in the printing and dyeing production process. In the concentrated waste water of 100t / d concentrated solution, 48t / d waste water and pure methanol are diverted to prepare a methanol-waste liquid mixed solution with a concentration of 15wt%, which enters the methanol storage tank 7, and the remaining 52t / d waste liquid is mixed with 1t / d printing and dyeing The sludge enters the waste liquid storage tank 5.

[0031] When the system is started, methanol and demineralized water enter the methanol storage tank 7 and are prepared into a 15wt% methanol aqueous solution. After the methanol aqueous solution is pressurized to 25MPa by the second high-pressure pump 8, it is heated to the light-off temperature by the methanol starting preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com