Preparation method and application of silane coupling agent modified magnetic halloysite material

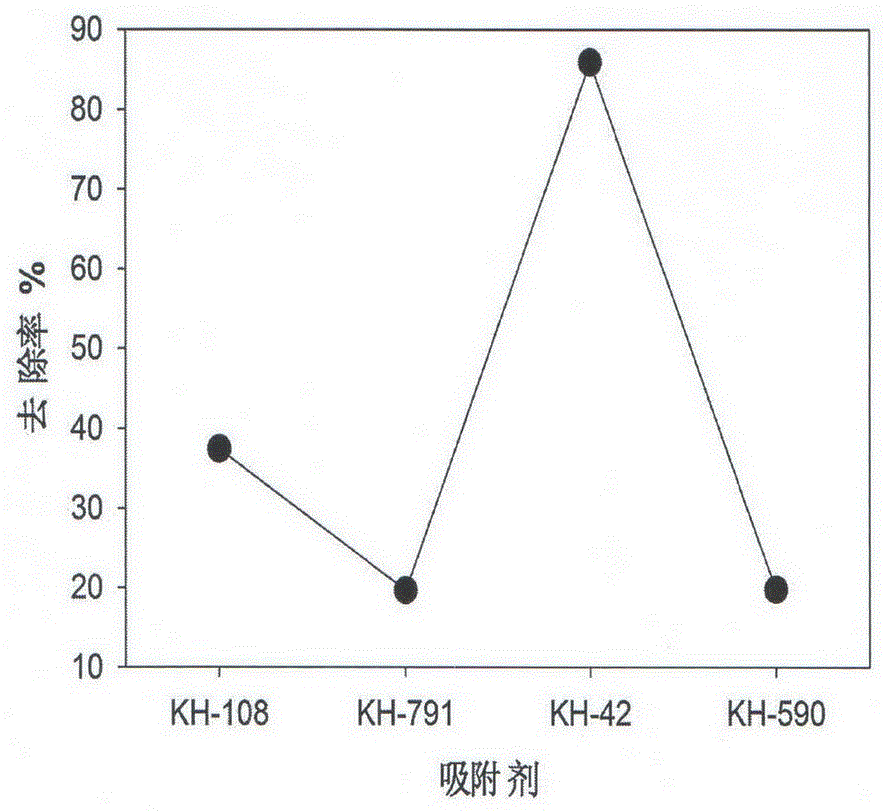

A technology of silane coupling agent and halloysite, which is applied in the cross field of environment and materials, can solve the problems of difficult separation of halloysite and low removal rate of pollutants, and achieve convenient and fast separation, high removal rate and strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

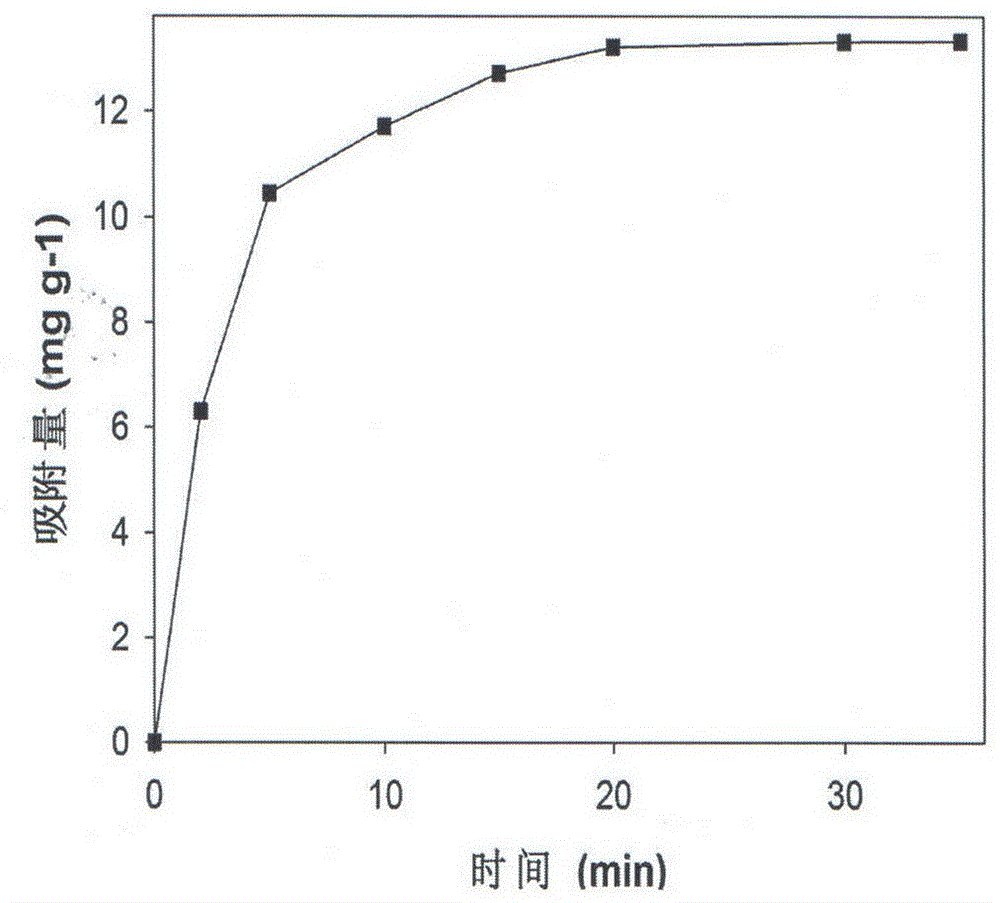

Method used

Image

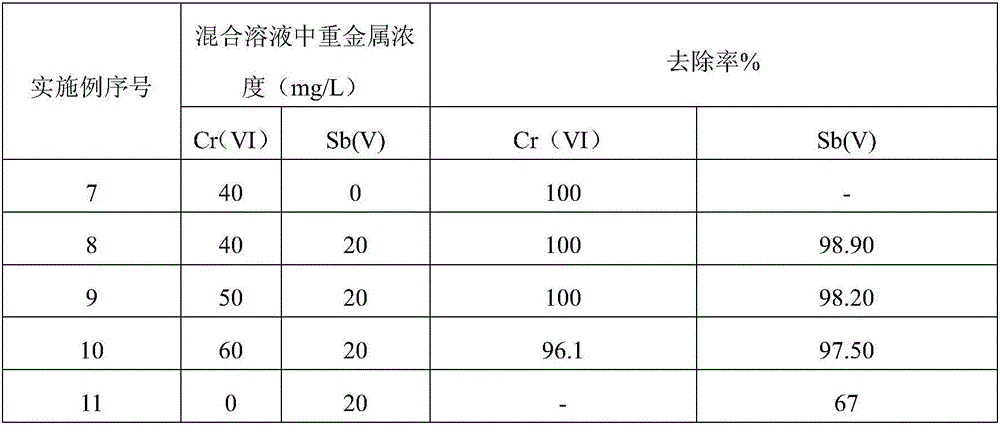

Examples

Embodiment 1

[0018] Preparation of magnetic halloysite modified by silane coupling agent:

[0019] a. Acidification of halloysite: take halloysite powder and put it into a beaker with a concentration of 0.1mol / L HCl solution, stir at room temperature for 10 hours, then rinse repeatedly with distilled water, and centrifuge until the supernatant is neutral. dry and ready for use;

[0020] b. Iron-saturated halloysite: add the halloysite, ferric chloride hexahydrate and deionized water acidified in step a into the beaker according to the mass ratio of 10:1:100, mechanically stir for 24 hours, and centrifuge and discard The supernatant was repeated 3 times in this way, and dried to obtain an iron-saturated halloysite suspension, which was set aside;

[0021] c. Preparation of magnetic halloysite: under the protection of nitrogen, quickly add ammonia water to the iron-saturated halloysite suspension in step b, and stir vigorously to adjust the pH to 9-10, then slowly add sulfuric acid heptahyd...

Embodiment 2

[0026] a. Acidification of halloysite: put halloysite powder into a beaker, add HCl solution with a concentration of 0.1mol / L, stir at room temperature for 10 hours, then rinse repeatedly with distilled water, and centrifuge until the supernatant is neutral. dry and ready for use;

[0027] b. Iron-saturated halloysite: add the acidified halloysite, ferric chloride hexahydrate and deionized water into the beaker at a mass ratio of 10:1:100, mechanically stir for 24 hours, centrifuge and discard the supernatant solution, so repeated 3 times, dried to obtain iron-saturated halloysite suspension, for subsequent use;

[0028] c. Preparation of magnetic halloysite: under the protection of nitrogen, quickly add ammonia water to the iron-saturated halloysite suspension in step b, and stir vigorously to adjust the pH to 9-10, then slowly add sulfuric acid heptahydrate Ferrous until the suspension turns black, condense and reflux at 70°C for 3 hours, separate under a strong magnet to o...

Embodiment 3

[0032]a. Acidification of halloysite: put halloysite powder into a beaker, add HCl solution with a concentration of 0.1mol / L, stir at room temperature for 10 hours, then rinse repeatedly with distilled water, and centrifuge until the supernatant is neutral. dry and ready for use;

[0033] b. Iron-saturated halloysite: add the acidified halloysite, ferric chloride hexahydrate and deionized water into the beaker at a mass ratio of 10:1:100, mechanically stir for 24 hours, centrifuge and discard the supernatant solution, so repeated 3 times, dried to obtain iron-saturated halloysite suspension, for subsequent use;

[0034] c. Preparation of magnetic halloysite: under the protection of nitrogen, quickly add ammonia water to the iron-saturated halloysite suspension in step b, and stir vigorously to adjust the pH to 9-10, then slowly add sulfuric acid heptahydrate Ferrous until the suspension turns black, condense and reflux at 70°C for 3 hours, separate under a strong magnet to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com