Method for extracting lignite wax from lignite

A technology for montan wax and lignite, which is applied in the chemical industry, can solve the problems of difficult recovery and utilization of mixed solvents, high quality of montan wax products, low extraction rate of extraction solvent, etc., and achieves the effects of low toxicity, low environmental hazard and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

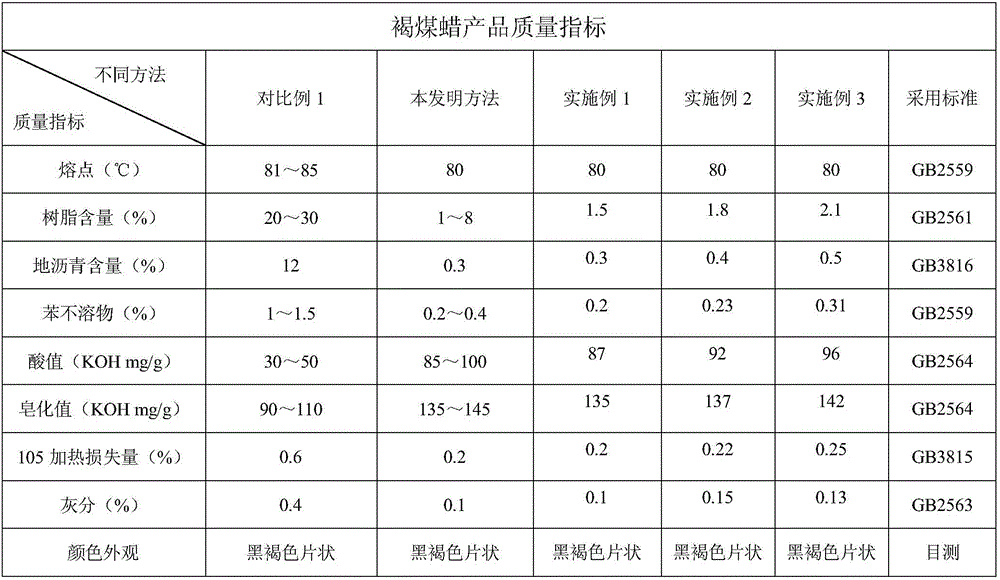

Examples

Embodiment 1

[0035] (1) prepare lignite particles:

[0036]Put the lumpy lignite into a pulverizer to pulverize, and pass through 0.3mm and 0.1mm sieves respectively to obtain lignite particles with a particle size of 0.1 to 0.3mm, and add lignite fine powder with a particle size of less than 0.1mm to a granulator to obtain granules Diameter is the lignite particle of 0.1~0.3mm, puts the obtained lignite particle in 60 ℃ of ovens and dries, until the water content of lignite particle is calculated as 1% by mass percentage;

[0037] (2) Prepare a solution containing montan wax:

[0038] Add 100 g of the dried lignite particles in step (1) to 100 g of n-butanol, and extract with stirring for 2 hours at 90° C., with a mixer speed of 200 r / min; filter the extract with suction to obtain filtrate B and filter residue A, and then Wash the filter residue with 100 g of n-butanol at 90° C., combine the filtrate B and the washing liquid C to obtain a solution D containing montan wax;

[0039] (3) o...

Embodiment 2

[0043] (1) prepare lignite particles:

[0044] Put the lumpy lignite into a pulverizer to pulverize, pass through 0.9mm and 0.3mm sieves respectively to obtain lignite particles with a particle size of 0.3-0.9mm, and add lignite fine powder with a particle size of less than 0.3mm to a granulator to obtain granules Diameter is the brown coal particle of 0.3~0.9mm, puts the obtained brown coal particle in 70 ℃ of ovens and dries, until the water content of brown coal particle is calculated as 3% by mass percentage;

[0045] (2) Prepare a solution containing montan wax:

[0046] Add 150 g of the dried lignite particles in step (1) to 450 g of n-amyl alcohol, and extract with stirring for 3 hours at 95° C., with a mixer speed of 200 r / min; filter the extract with suction to obtain filtrate B and filter residue A, and then Wash the filter residue with 200 g of n-amyl alcohol at 95° C., combine the filtrate B and the washing liquid C to obtain a solution D containing montan wax;

...

Embodiment 3

[0051] (1) prepare lignite particles:

[0052] Put the lumpy lignite into a pulverizer to pulverize, pass through 0.9mm and 1.2mm sieves respectively to obtain lignite particles with a particle size of 0.9-1.2mm, and add lignite fine powder with a particle size of less than 0.9mm to a granulator to obtain granules Diameter is the lignite particle of 0.9~1.2mm, puts the obtained lignite particle in 80 ℃ of ovens and dries, until the water content of lignite particle is calculated as 5% by mass percentage;

[0053] (2) Prepare a solution containing montan wax:

[0054] Add 200 g of the dried lignite particles in step (1) to 800 g of isoamyl alcohol, and extract with stirring for 4 hours at 100° C., at a mixer speed of 300 r / min; filter the extract with suction to obtain filtrate B and filter residue A, and then Wash the filter residue A with 300 g of isoamyl alcohol at 100° C., combine the filtrate B and the washing liquid C to obtain a solution D containing montan wax;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com