Method for producing low-condensation-point diesel oil and liquid paraffin by using coal tar

A technology for liquid paraffin and coal tar, which is applied in the recovery/refining of mineral wax, petroleum industry, processing of hydrocarbon oil, etc. Economic benefits and the effect of improving the utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

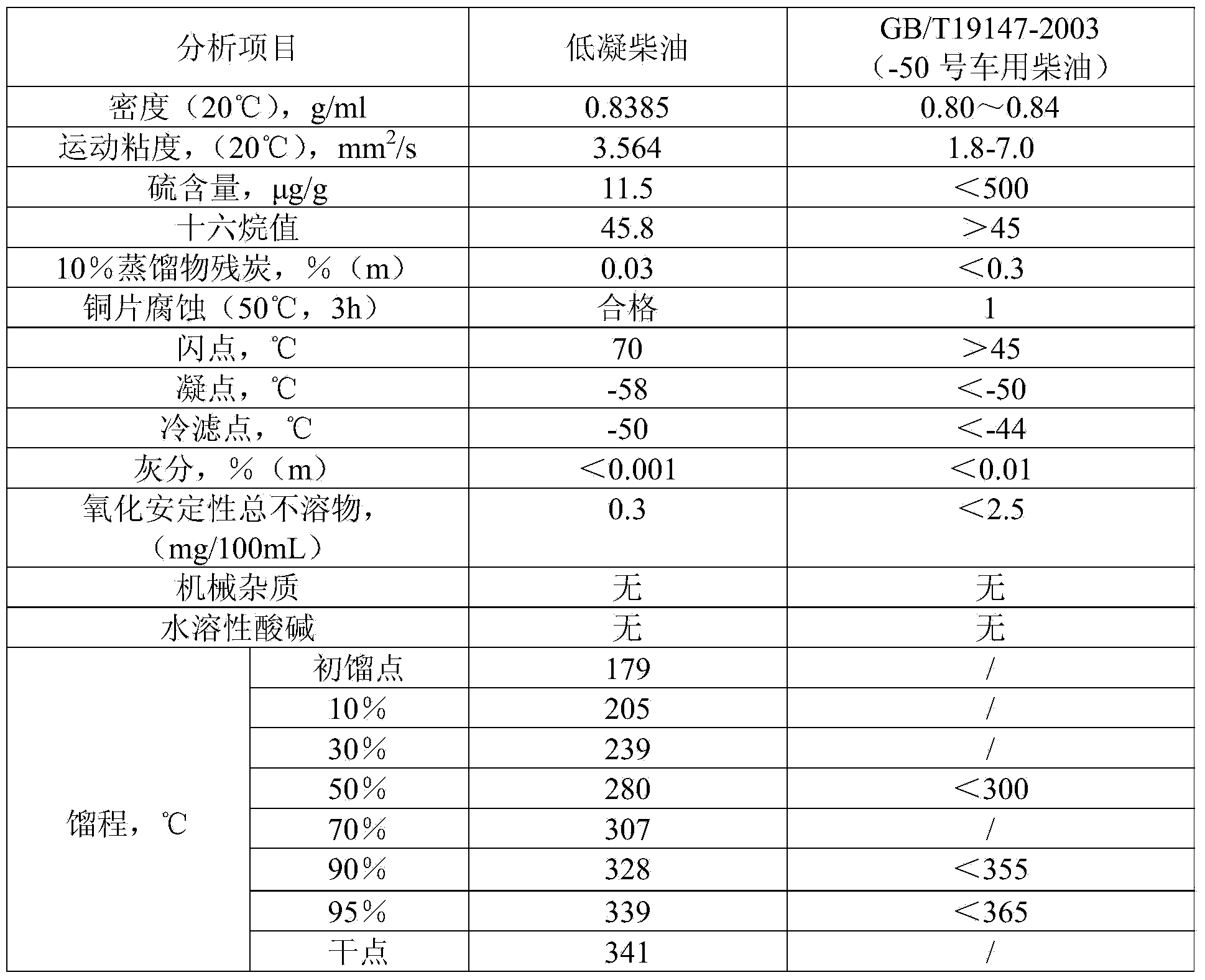

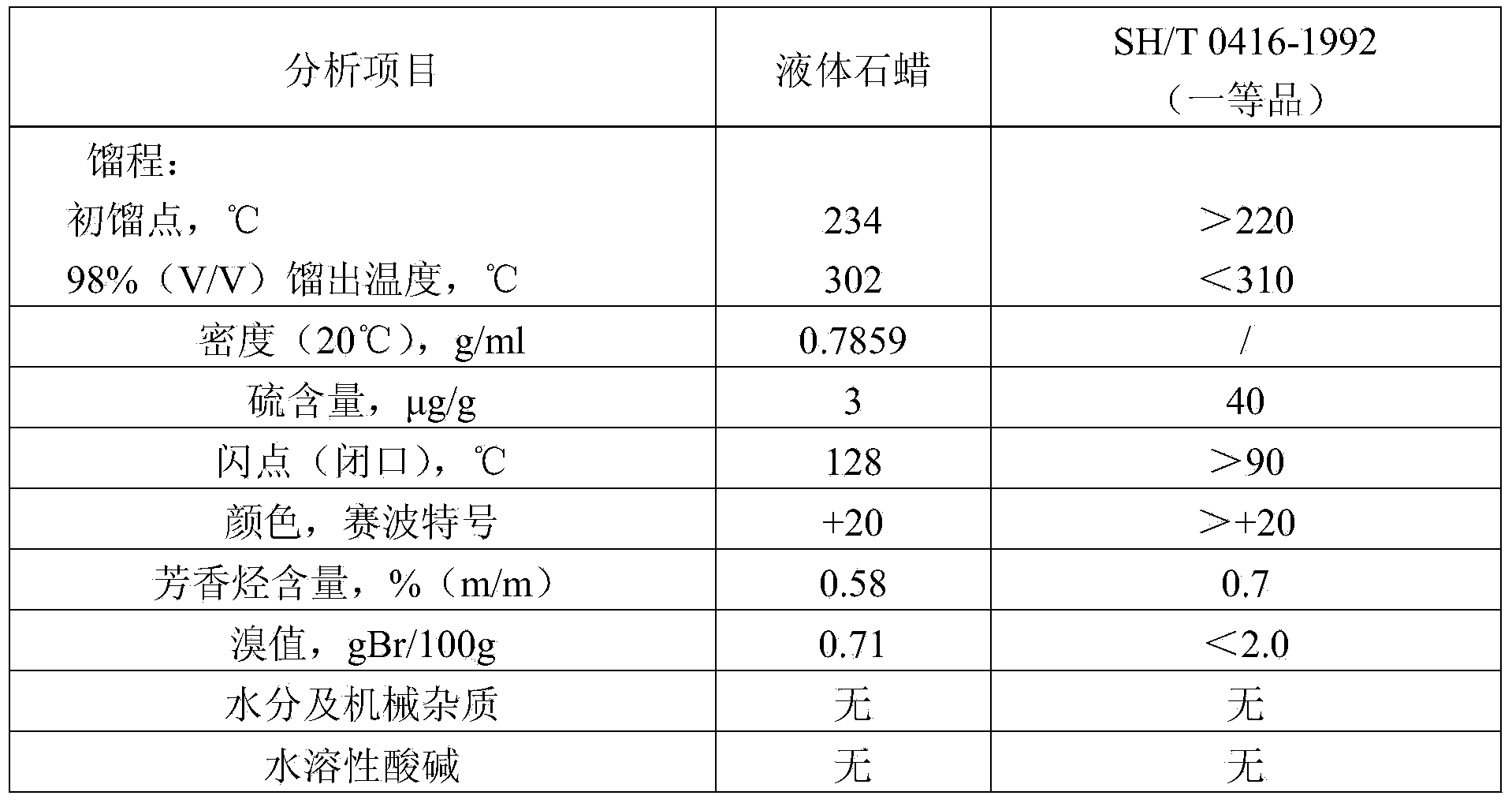

Examples

Embodiment 1

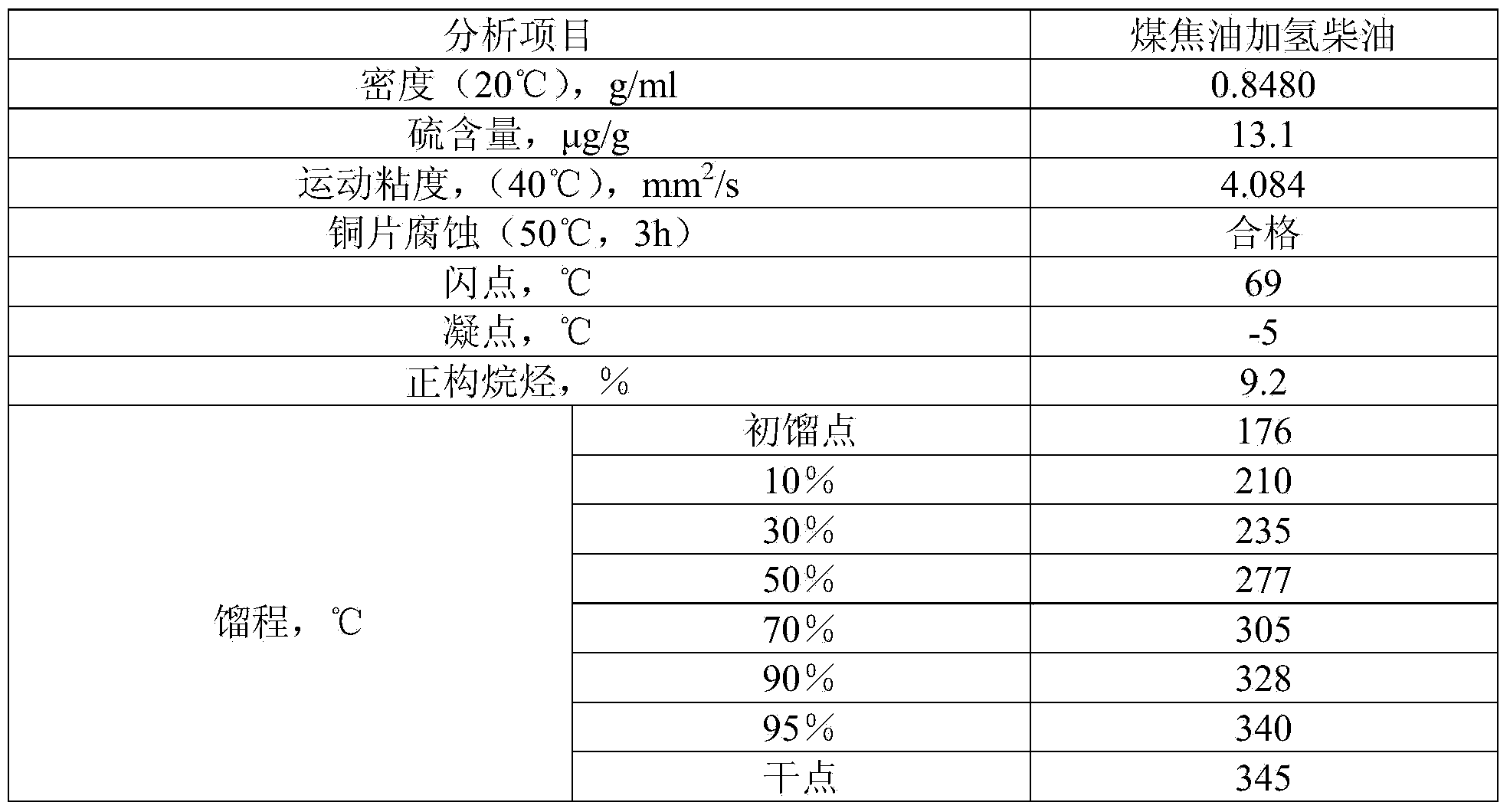

[0026] Taking the raw material as an example of 500-700°C low-temperature coal tar produced during coal gasification, coking or semi-coke production, the method for producing low-point diesel and liquid paraffin is realized by the following steps:

[0027] (1) Mild hydrofining of coal tar

[0028] Coal tar and hydrogen are mixed and then mildly hydrogenated and refined in a hydrogenation reactor under the catalysis of a molybdenum-nickel catalyst. Airspeed is 0.7h -1 , to obtain hydrorefining oil;

[0029] The molybdenum-nickel catalyst in this example is the RDM-2 catalyst developed by Beijing Petroleum Science Research Institute (http: / / www.qmchj.com / products_detail / &productId=6.html), which is based on aluminum oxide As a carrier, the content of molybdenum trioxide in the catalytically active metal is 10wt%, the content of nickel oxide is 2wt%, the total pore volume is greater than 0.6mL / g, and the specific surface area is greater than 100m 2 / g.

[0030] (2) Fractional...

Embodiment 2

[0047] Taking the medium and low temperature coal tar produced in the process of coal gasification, coking or semi-coke as the raw material as an example, the method for producing low-point diesel oil and liquid paraffin is realized by the following steps:

[0048] (1) Mild hydrofining of coal tar

[0049] Coal tar and hydrogen are mixed and then mildly hydrogenated and refined in a hydrogenation reactor under the catalysis of a molybdenum-nickel catalyst. Airspeed is 0.65h -1 , to obtain hydrorefining oil;

[0050]The molybdenum-nickel catalyst in this example is the FZC-204 catalyst developed by Fushun Petrochemical Research Institute (http: / / www.sinopec-catalyst.com / product / detail / id / 28.html), which is based on Aluminum oxide is used as the carrier, the content of molybdenum trioxide in the catalytically active metal is 15wt%, the content of nickel oxide is 4wt%, the total pore volume is greater than 0.6mL / g, and the specific surface area is greater than 100m 2 / g.

[0...

Embodiment 3

[0056] In the above-mentioned Examples 1-2, step (1) is to mix coal tar and hydrogen and carry out mild hydrogenation refining under the catalytic action of molybdenum-nickel catalyst in the hydrogenation reactor. The reaction temperature is 320°C and the reaction pressure is is 9MPa, the volume ratio of hydrogen to oil is 950:1, and the liquid volume space velocity is 0.8h -1 , to obtain hydrofining to generate oil; the molybdenum-nickel type catalyst used is based on aluminum oxide as a carrier, and the content of molybdenum trioxide in its catalytically active metal is 6wt%, the content of nickel oxide is 1wt%, and the total pore volume is greater than 0.6mL / g, the specific surface area is greater than 100m 2 / g. Step (3) is to mix isopropanol, urea and water to form urine, saturate the urine at 60°C in the reactor, add diesel oil at a volume ratio of 1:3.5, stir, and decomplex The wax was reacted for 1.5 hours, and the final temperature of the reaction was 30°C. After s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com