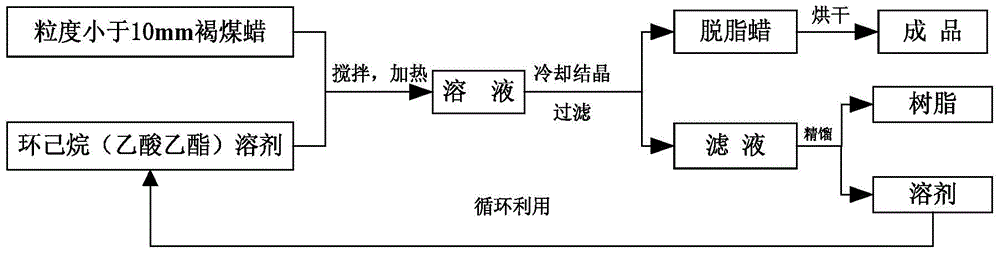

Solvent and method for removing resin from lignite wax by virtue of crystallization process

A technology of montan wax and crystallization method, which is applied in the recovery/refining of mineral wax and the petroleum industry, etc. It can solve the problems of difficult resin removal and inability of solvent to fully enter the inside of particles, and achieves short processing time, little harm to human body, and ecological protection. Environmentally harmless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of montan wax deresinization method with cyclohexane as solvent, concrete steps are:

[0019] Take 1 ton of montan wax particles with a resin content of 28.3% and a particle size of less than 10mm, place the montan wax particles in a jacketed crystallization kettle, and inject cyclohexane solvent into the crystallization kettle using a solvent pump, the montan wax particles and cyclohexane solvent The ratio of material to liquid is 1:35, stirring, heating (steam goes through the jacket), the pressure is controlled at 2.0MPa, and the heating is maintained for 20 minutes. Cut off the water vapor, add cooling water to the jacket of the crystallization kettle to cool the solution in the crystallization kettle, keep the temperature of the solution in the crystallization kettle at 20°C, and cool and crystallize for 30 minutes. Use a circulating water vacuum pump to perform suction filtration to separate the filter residue from the solution, and dry the ob...

Embodiment 2

[0020] Embodiment 2: a kind of montan wax deresinization method with ethyl acetate as solvent, concrete steps are:

[0021] Take 1 ton of montan wax particles with a resin content of 29.1% and a particle size of less than 10mm, put the montan wax particles in a crystallization kettle, inject ethyl acetate solvent into the crystallization kettle using a solvent pump, and the feed liquid of the montan wax particles and ethyl acetate solvent The ratio is 1:30, stirring, heating, the pressure is controlled at 3.0MPa, and the heating is maintained for 20 minutes. Then cool the solution with cooling water, keep the temperature at 20°C, and crystallize by cooling for 30 minutes. Then use a circulating water vacuum pump to perform suction filtration, and dry the obtained filter residue in a product dryer at 40° C. to obtain a finished product of montan wax. The degreasing rate was measured according to GB2561-81, and it was found that the degreasing rate of montan wax was 30.28%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com