Method for extracting montan wax from lignite

A production method and a montan wax technology are applied in the chemical industry and can solve the problems of small output, difficulty in preparing montan wax, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

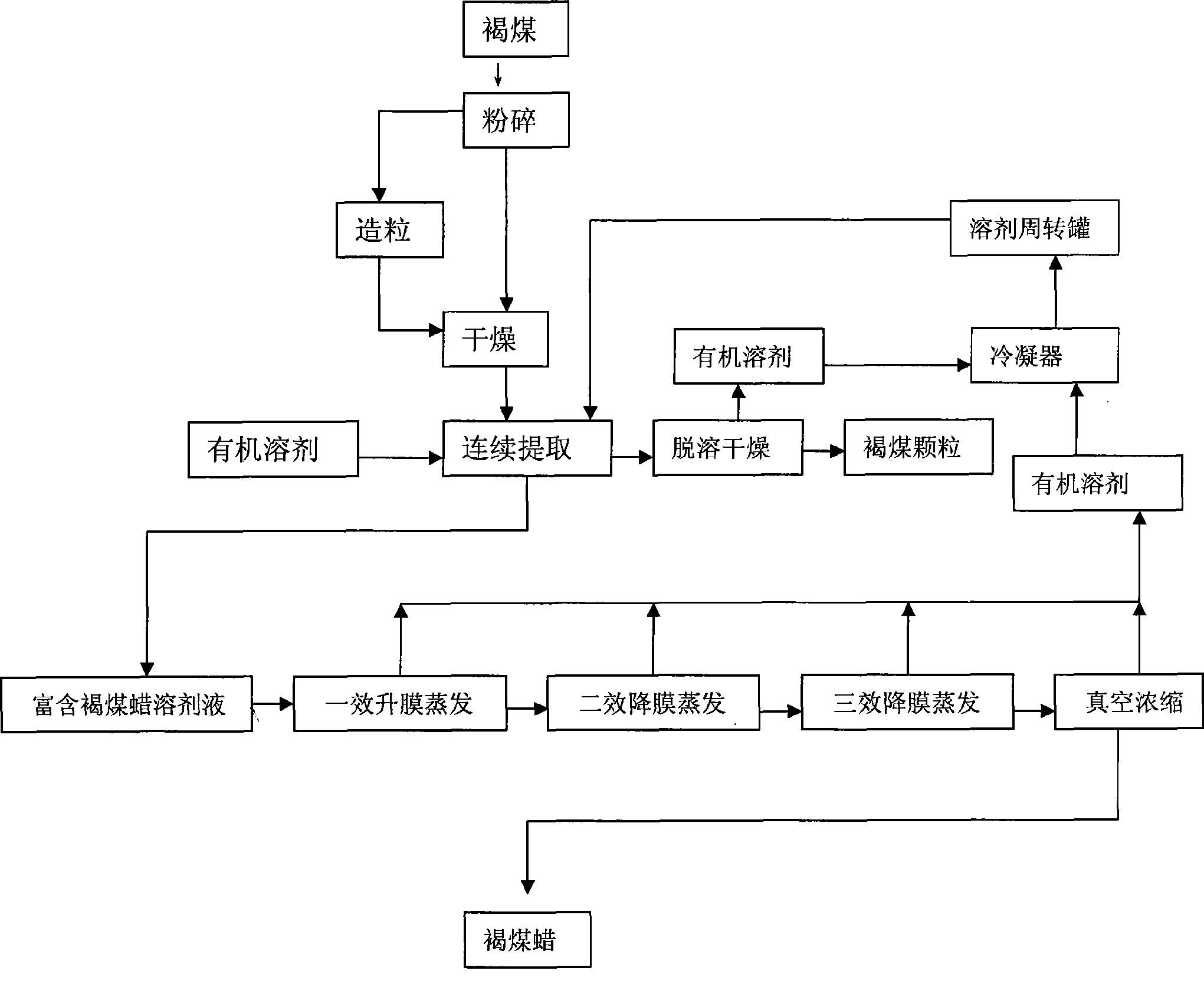

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] Shown in accompanying drawing, the present invention is realized by the following steps:

[0009] 1. Crushing: The lignite mined from the mine has different volumes. For large lump lignite, it is not conducive to granulation in the subsequent process section, and it needs to be further crushed into a powder with a particle size of 2-8mm;

[0010] 2. Granulation: In order to increase the contact area between coal and solvent, ensure the penetration gap and penetration speed, and make full use of materials, at the same time, for some fine dust lignite with particle size less than 2mm, use granulation equipment to make the diameter 2-8mm left and right lignite particles;

[0011] 3. Drying: Since the raw material contains about 40% water, the water in the lignite seriously affects the penetration and extraction effect of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com