Graphene oxide/polystyrene nano composite and preparation method thereof

A technology of polystyrene nanocomposite materials, applied in the field of graphene oxide/polystyrene nanocomposite materials, which can solve the problem of poor bonding interface between graphene oxide sheets and polymers, low comprehensive performance of composite materials, and dispersion Inhomogeneity and other problems, to achieve the effect of easy industrial implementation, easy operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

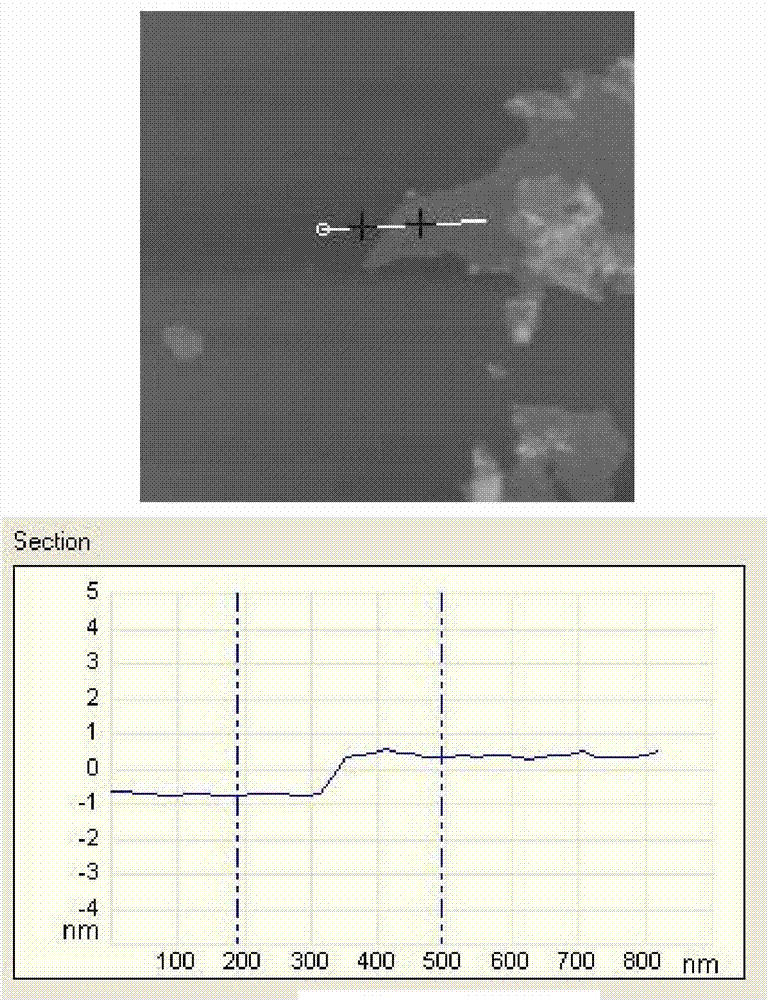

Image

Examples

Embodiment 1

[0023] 1. Preparation of graphene oxide

[0024] Add 230mL of concentrated sulfuric acid with a mass concentration of 98% and 5g of sodium nitrate into a dry beaker, and cool in an ice-water bath. When the temperature of the system is lower than 5°C, stir and add 10g of flake graphite, mix well and slowly add 30g of potassium permanganate (KMnO 4 ), control the reaction temperature at 10-15°C, place the beaker in a constant temperature water bath at 35°C after reacting for 2 hours, continue stirring and reacting for 2 hours, add 460mL of deionized water by continuously adding water, and control the temperature of the reaction solution at 98°C , continue to stir for 30min, add 1.4L of deionized water to terminate the reaction, then add 25mL of 30% hydrogen peroxide, filter while hot, and wash the product with dilute hydrochloric acid (1:10 volume ratio) until there is no SO in the filtrate 4 2- (BaC1 2 The solution was tested for no precipitation), and then washed with deion...

Embodiment 2

[0031] 1, the preparation method of graphene oxide is the same as embodiment 1.

[0032] 2. Preparation of Pickering emulsion

[0033] Add 60 mg of graphene oxide prepared in step 1 to 40 mL of NaCl solution with a concentration of 0.5 M. After stirring, a uniform dispersion system of graphene oxide and salt is formed, and 2.0 g of styrene monomer is added to the resulting dispersion system, and ultrasonically Disperse for 10-60 minutes to form a stable Pickering emulsion with a styrene concentration of 0.48mol / L.

[0034] 3. Polymerization

[0035] 10 mg initiator K 2 S 2 o 8 Add it into the Pickering emulsion, stir and react at 65-85°C for 2-6 hours, cool to room temperature after the reaction, filter, wash and vacuum-dry to obtain a graphene oxide / polystyrene composite material.

Embodiment 3

[0037] 1, the preparation method of graphene oxide is the same as embodiment 1.

[0038] 2. Preparation of Pickering emulsion

[0039] 100mg of graphene oxide prepared in step 1 is added to 40mL of NaCl solution with a concentration of 0.2M. After stirring, a uniform dispersion system of graphene oxide and salt is formed, and 2.0g of styrene monomer is added to the resulting dispersion. Ultrasonic dispersion for 10-60 minutes forms a stable Pickering emulsion with a styrene concentration of 0.48mol / L.

[0040] 3. Polymerization

[0041] 10 mg initiator K 2 S 2 o 8 Add it into the Pickering emulsion, stir and react at 65-85°C for 2-6 hours, cool to room temperature after the reaction, filter, wash and vacuum-dry to obtain a graphene oxide / polystyrene composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com