PDLC grating of lcd equipment and making method

A technology of liquid crystal display and manufacturing method, which is applied in the direction of optomechanical equipment, chemical instruments and methods, optics, etc., can solve the problems of affecting the use effect of PDLC grating 11, blurring of liquid crystal display images, and insufficient transparency, so as to eliminate blurring and improve Display quality, effect of improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

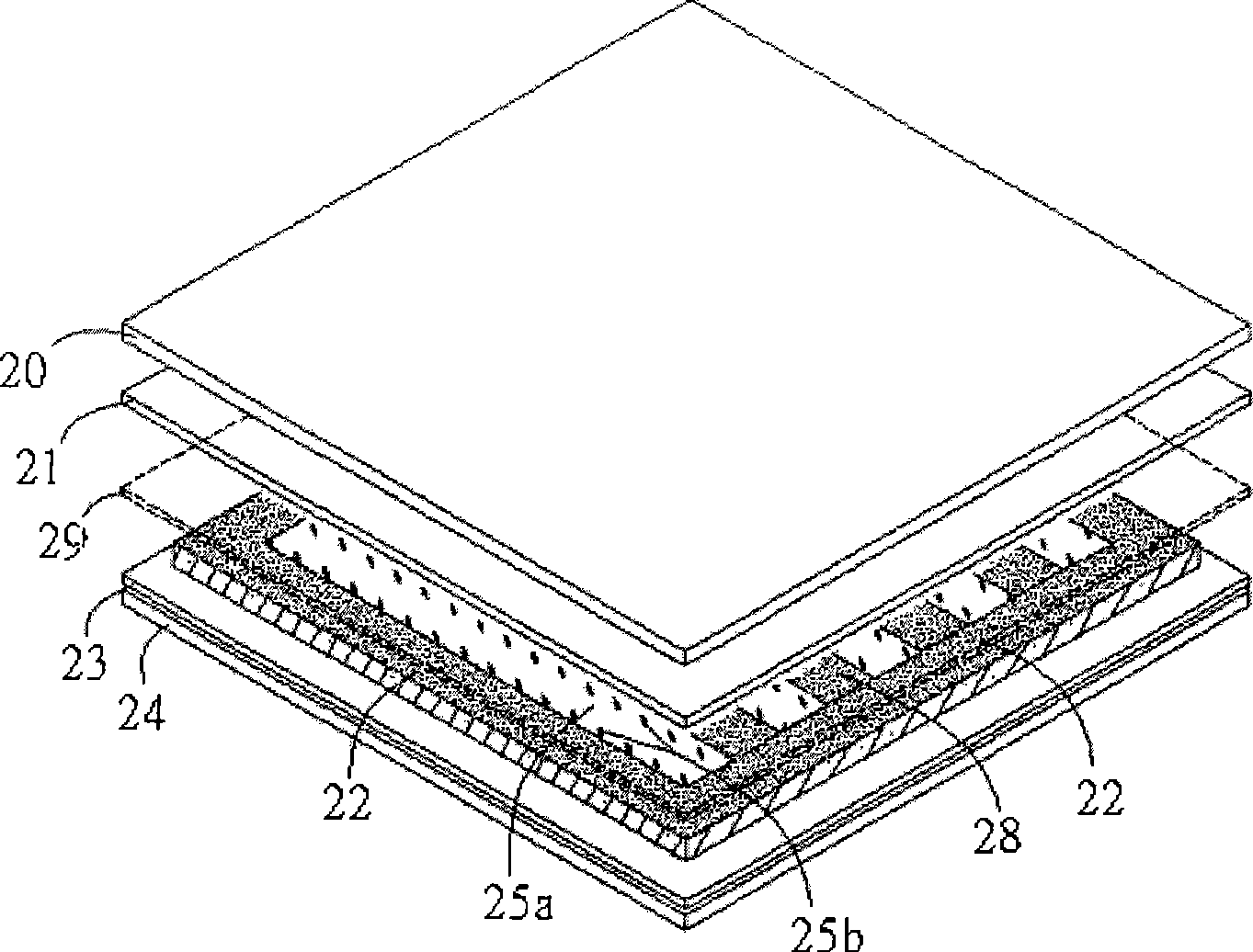

[0036] like figure 2 The PDLC grating of the liquid crystal display device of the embodiment of the present invention is shown, including: a first substrate 24, a first electrode layer 23, a second substrate 20, a second electrode layer 21, a grid-like photoresist spacer 28, and a polymer 25a , the liquid crystal droplet 25b and the frame 22.

[0037] Wherein the first electrode layer 23 is placed on the upper surface of the first substrate 24, and the second electrode layer 21 is placed on the lower surface of the second substrate 20. The material of the first electrode layer 21 and the second electrode layer 20 can be selected from ITO (indium tin oxide) Grid-shaped photoresist spacers 28 are located between the first electrode layer 23 and the second electrode layer 21, and liquid crystal droplets 25b and polymers 25a are distributed between adjacent grid-shaped photoresist spacers 28.

[0038] The working principle of this embodiment: when an electric field is applied betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com