Liquid crystal display element and manufacturing method thereof

a technology of liquid crystal display element and manufacturing method, which is applied in the direction of optics, instruments, non-linear optics, etc., can solve the problems of large amount of paper consumed mainly in offices, consumption of paper meant for short-lived documentation, and information consumption has tended to increase more, so as to achieve superior threshold steepness and superior display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Coating Solution for Display Layer

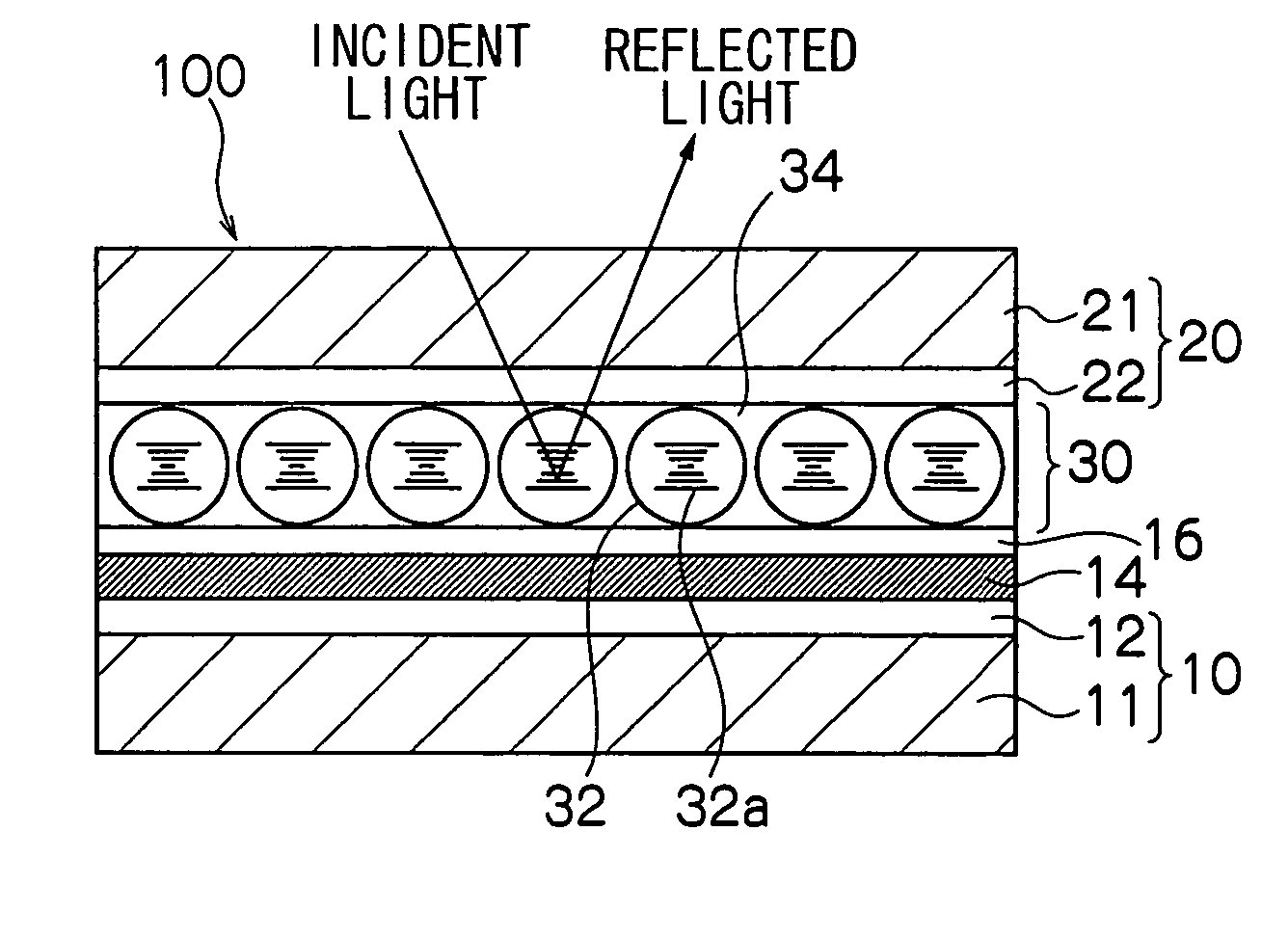

[0098] 77.5 mass % of nematic liquid crystal (E7 (trade name) manufactured by Merck & Co., Inc.), 18.8 mass % of a chiral agent 1 (CB15 (trade name) manufactured by Merck & Co., Inc.) and 3.7 mass % of a chiral agent 2 (R1011 (trade name) manufactured by Merck & Co., Inc.) are mixed to prepare cholesteric liquid crystal that selectively reflects light of green color.

[0099] The cholesteric liquid crystal is emulsified in a 0.25 mass % aqueous solution of sodium dodecylbenzenesulfonate at a nitrogen pressure of 0.12 kgf / cm2 with a membrane emulsification device (MICRO KIT (trade name) manufactured by SPG TECHNOLOGY Co., Ltd.) which includes a ceramic porous film having a pore side of 4.2 μm. The state of dispersion of the resultant emulsion, which includes cholesteric liquid crystal drops haing an average size of 14.9 μm and a size standard deviation of 1.32 μm, is close to monodisperse.

[0100] Next, the emulsion is allowed to stand ...

example 2

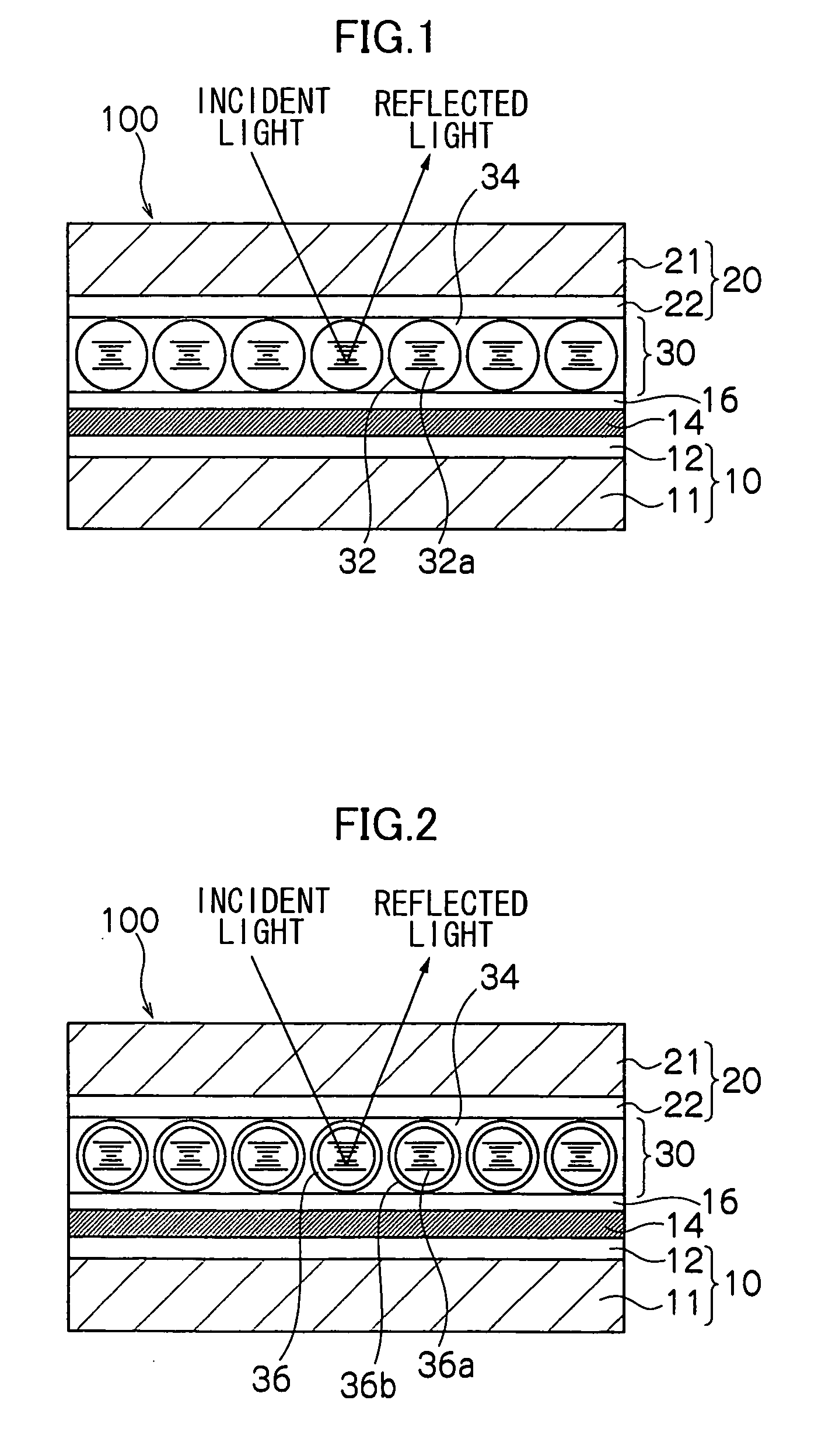

[0121] A cholesteric liquid crystal emulsion is prepared in the same manner as in Example 1. A water-soluble melamine-formalin resin (MX-035 (trade name) manufactured by Sanwa Chemical Industries, Ltd.) is added thereto such that the amount of the resin is one fifth of that of the cholesteric liquid crystal in terms of part by mass. They are reacted at 65° C. for 3 hours to obtain a slurry including microcapsules each of which has a shell made of the melamine-formalin resin and encapsulating the cholesteric liquid crystal. The average size of the microcapsules is 15.2 μm.

[0122] Next, the slurry is allowed to stand so as to the microcapsules to settle. The resultant supernatant is removed to obtain a condensed slurry. The ratio of volume of the microcapsules to that of the condensed slurry is measured with a densitometer (DMA35n (trade name) manufactured by Nihon SiberHegner K.K.) and found to be 0.482.

[0123] The ratio AL of an area covered by the liquid crystal micrcapsules to a c...

example 3

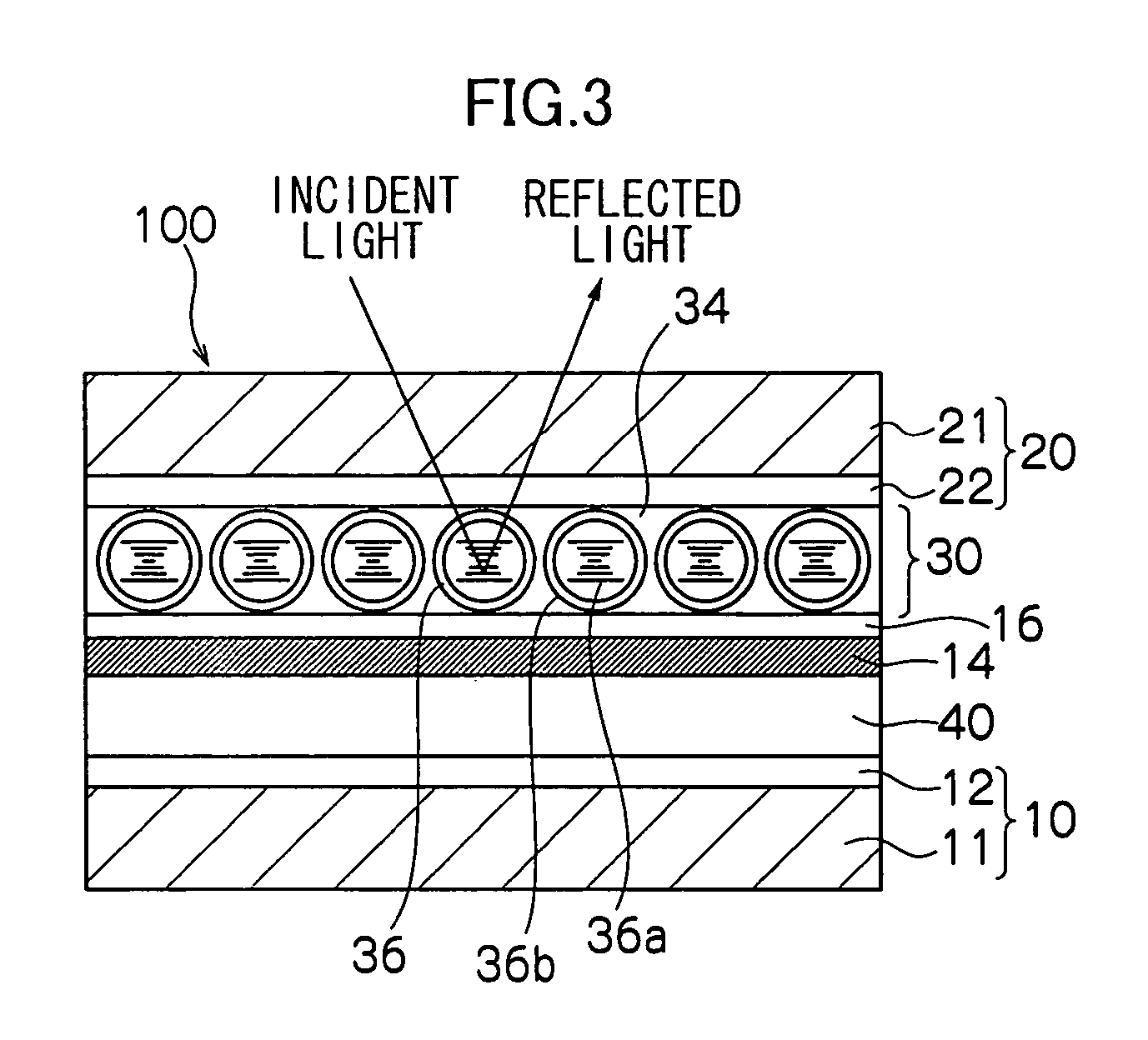

[0129] An adduct (Takenate D110N (trade name) manufactured by Takeda Chemical Industries, Ltd.) of xylene diisocyanate to trimethylolpropane at a ratio of 3:1 and ethyl acetate are added to the same cholesteric liquid crystal as in Example 1 so that the amount of each of these components is one fifth of that of the cholesteric liquid crystal in terms of part by mass. The resultant is stirred to obtain a uniform solution serving as an oil phase.

[0130] One part by mass of ethyl acetate is added to 10 parts by mass of a 1.0 mass % aqueous solution of partially saponified PVA having a polymerization degree of 500 and manufactured by Wako Pure Chemical Industries, Ltd., and the resultant is stirred at 70° C. and then cooled down to room temperature. Another uniform solution serving as an aqueous phase is obtained by removing a part of ethyl acetate which part has not been dissolved.

[0131] The oil phase is emulsified in the aqueous phase at a nitrogen pressure of 0.10 kgf / cm2 with a mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com