Device for controlling liquid crystal distribution and method for making liquid crystal display

A control device and temperature control device technology, which is applied to the device, instrument, optics and other directions of coating liquid on the surface, and can solve problems such as stains and poor picture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

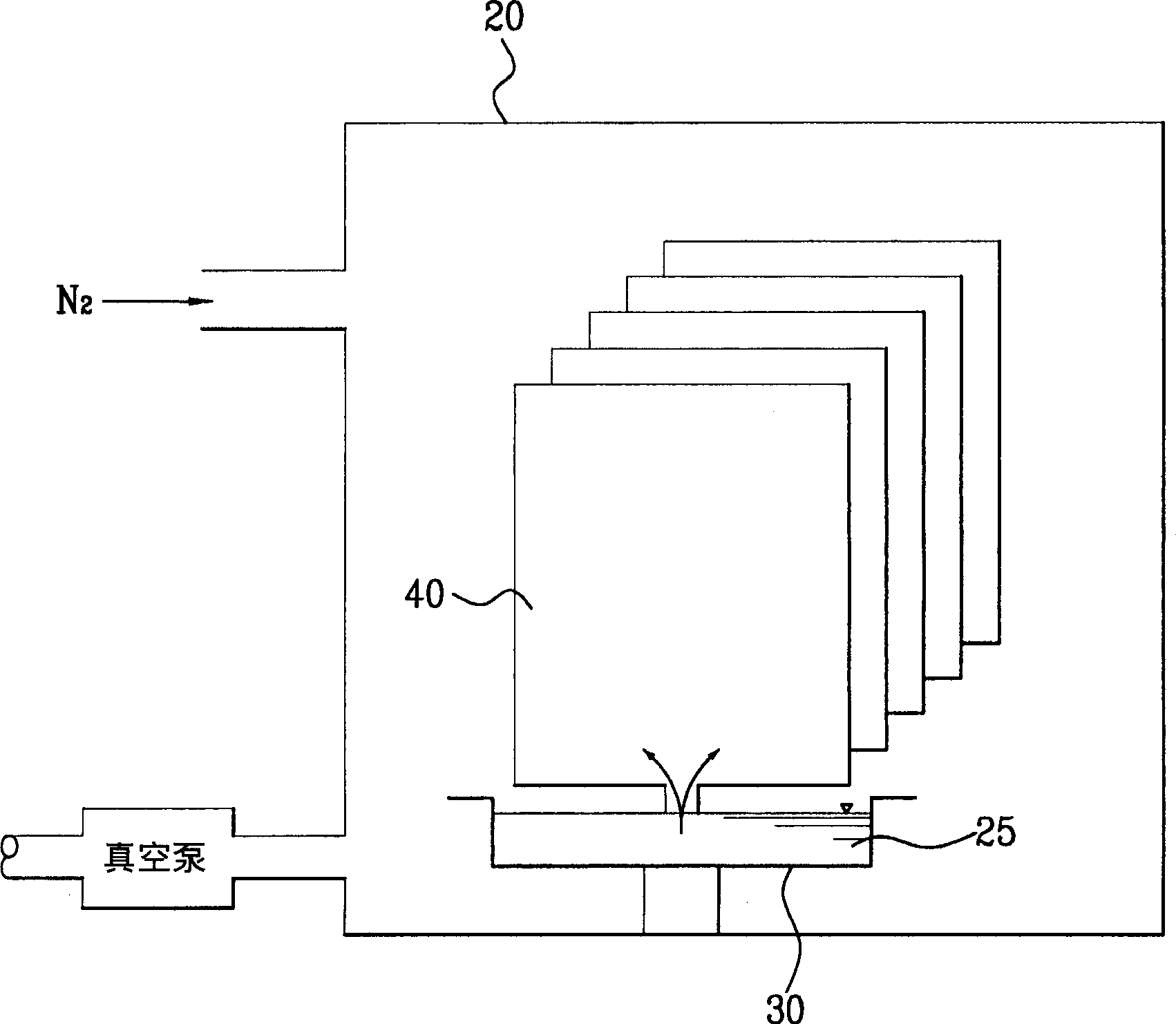

[0056] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings.

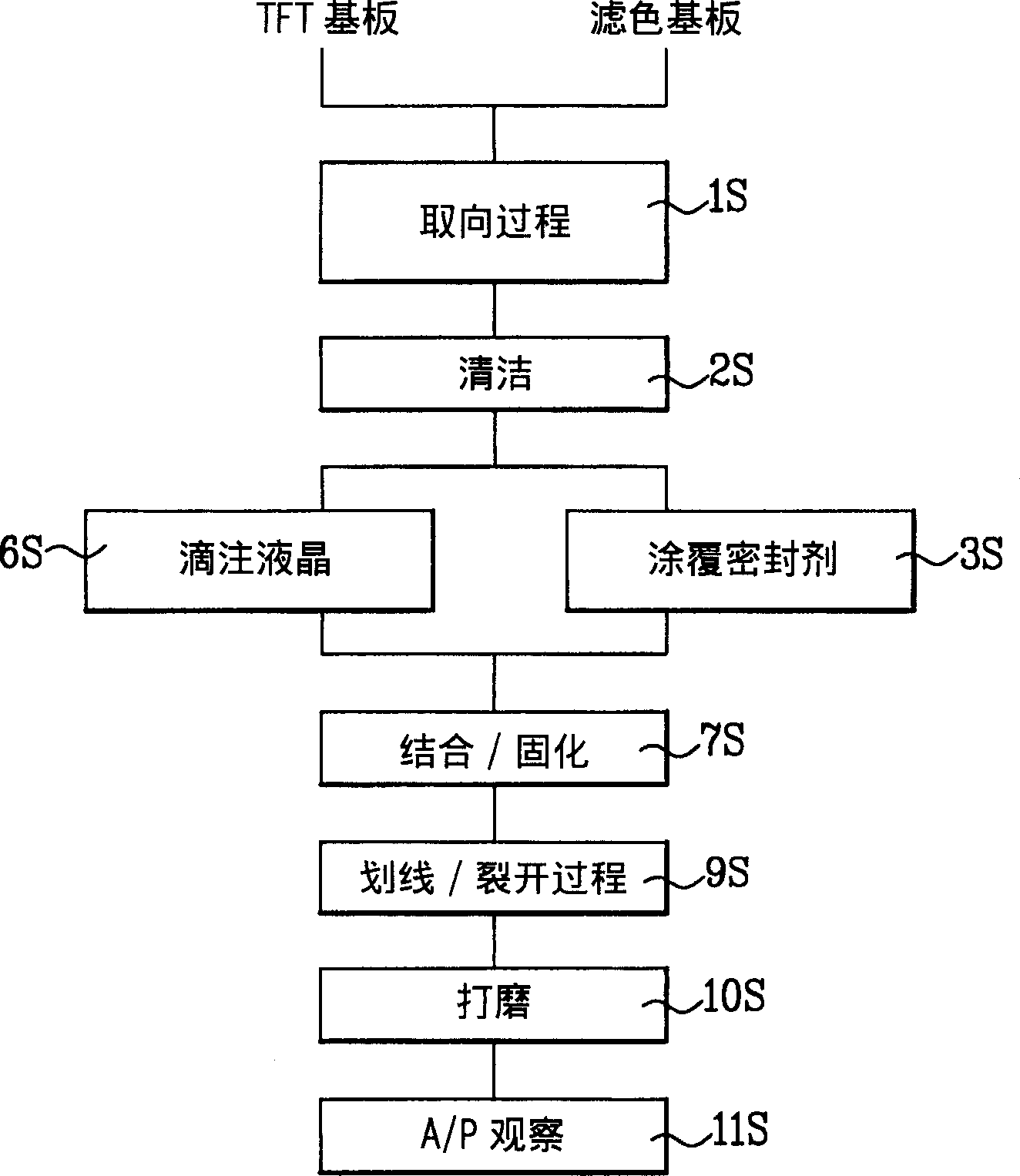

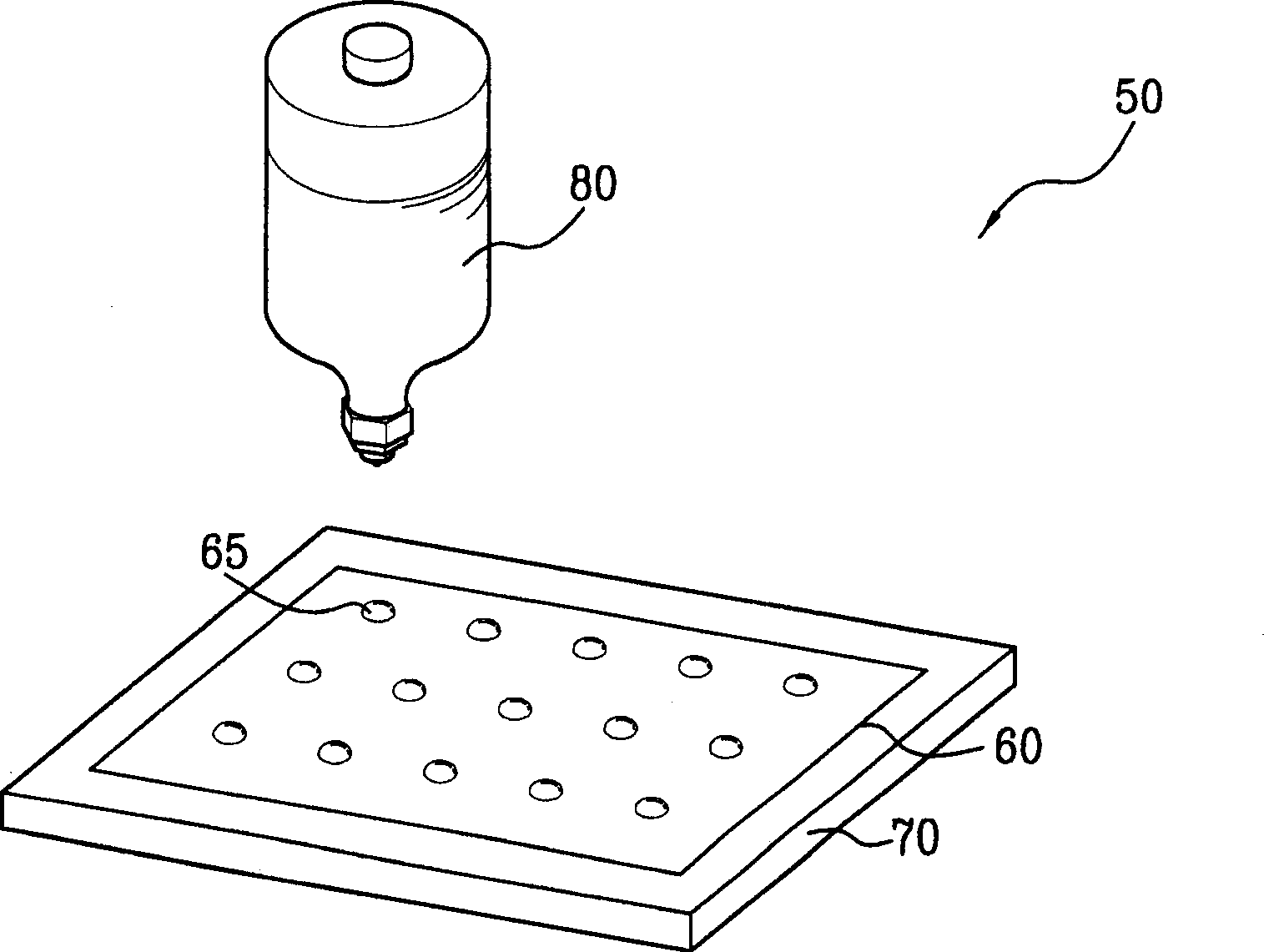

[0057] Image 6 A flow chart is shown for explaining an LCD manufacturing method to which a drip injection method according to an embodiment of the present invention is applied. Figure 7 A perspective view is shown for explaining the liquid crystal dropping method according to the embodiment of the present invention. Figure 8 Indicates the state after liquid crystal instillation.

[0058] Although not shown, the present invention provides first and second substrates that have undergone an arraying process and a color filter process. The first and second substrates respectively include a plurality of thin film transistor (TFT) unit substrate regions and color filter unit substrate regions. After the arraying process and the color filter process are completed, the first substrate and the second substrate are respectively loaded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com