Structure of liquid-crystal displaying device from liquid-crystal dripping process and production thereof

A liquid crystal display, liquid crystal dropping technology, applied in the direction of instruments, nonlinear optics, optics, etc., to achieve the effect of improving pollution and improving pre-hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It can be known from the above background of the invention that when the ODF process is used, an ultraviolet curable sealant is usually used to ensure the process yield. However, it is often found that the liquid crystals of the produced liquid crystal display panels are polluted. How to effectively improve the pollution of the liquid crystal display panels has become an important goal of the liquid crystal display panel manufacturers.

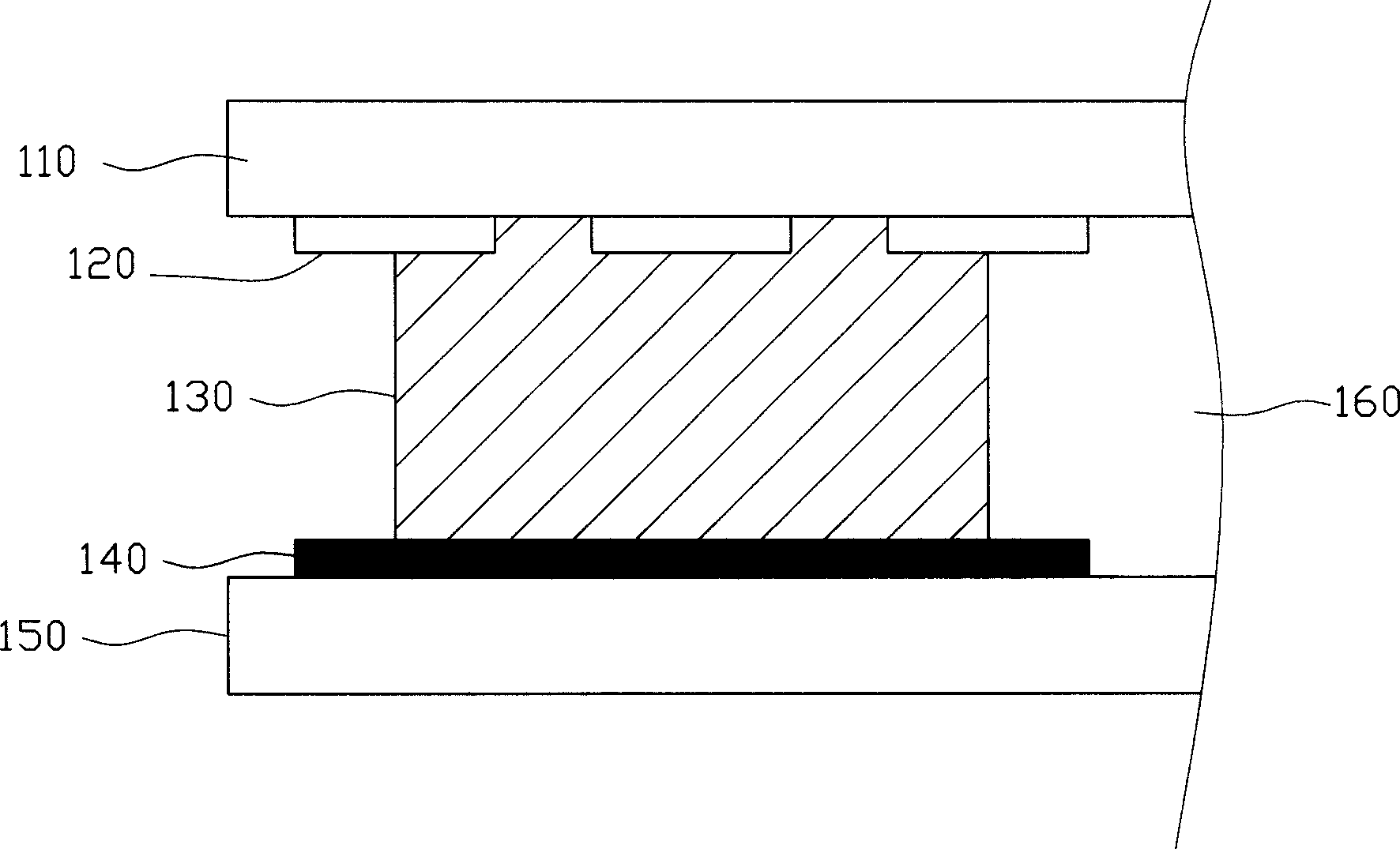

[0027] refer to figure 1 It is a schematic cross-sectional view of the local structure of the frame glue position of the TFT liquid crystal display of the present invention. As shown in the figure, the TFT liquid crystal display of the present invention has a first substrate 110 and a second substrate 150, both of which are made of transparent glass. Generally speaking, when making a liquid crystal display, the circuit of the conductive pattern layer 120 is hidden behind the light-shielding layer 140, and the wiring around the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com