Device used for controlling liquid crystal dripping

A liquid crystal droplet, liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as spots and defects on the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

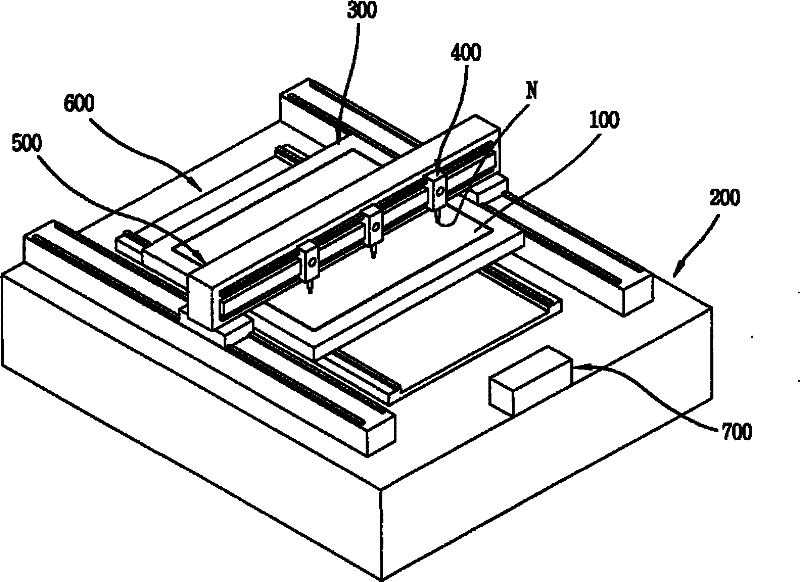

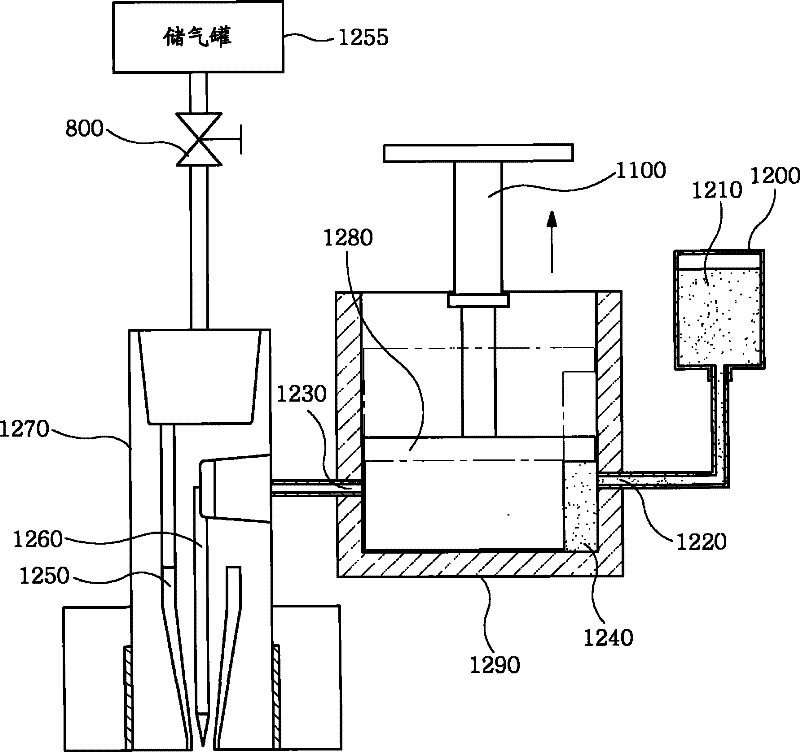

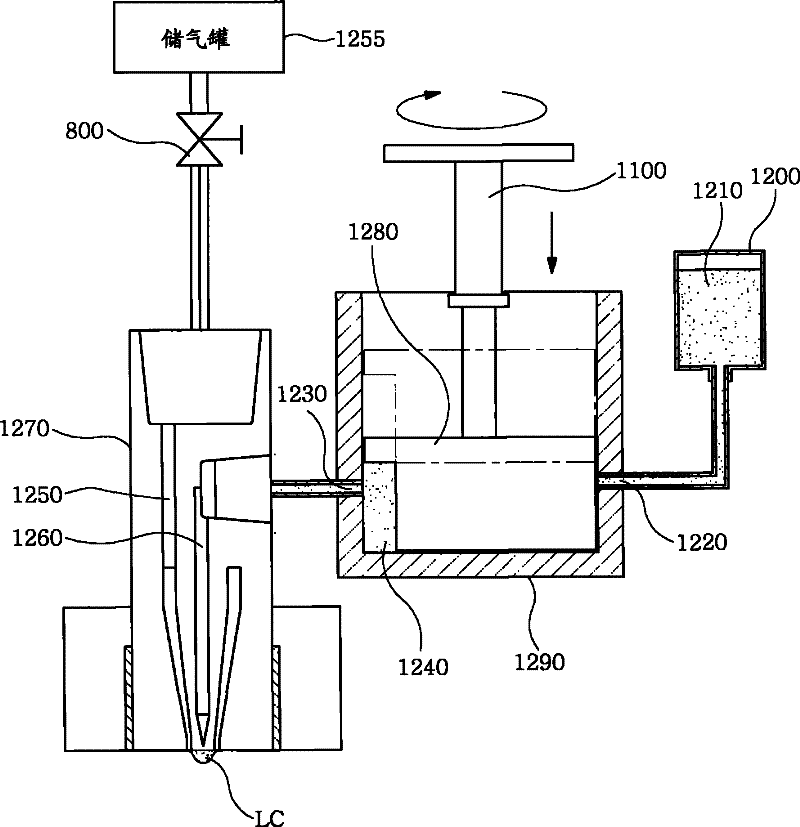

[0018] A device for controlling liquid crystal dripping according to an embodiment of the present invention mainly includes a head unit, a temporary liquid crystal (LC) storage unit, and a two-fluid control unit. The mechanical configuration and operation of the head unit and the temporary LC storage unit that can be driven by the two-fluid control unit will be described in detail with reference to the accompanying drawings. figure 2 and image 3 is a view showing a mechanical configuration of an apparatus for controlling liquid crystal dropping according to an embodiment of the present invention.

[0019] Such as figure 2 and image 3 As shown, a head unit 1270 has a gas supply path 1250 and a liquid crystal (LC) supply path 1260 therein. The liquid crystal fed via the LC supply path 1260 is dripped onto the substrate through nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com