Method used for liquid crystal dripping

A technology of liquid crystals and liquid crystal drops, applied in nonlinear optics, instruments, optics, etc., can solve problems such as spots and defects on the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

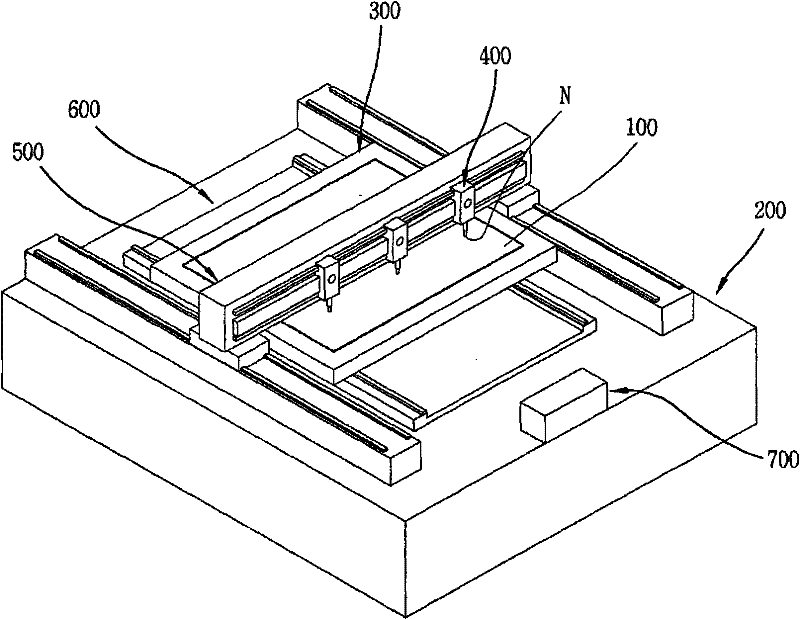

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

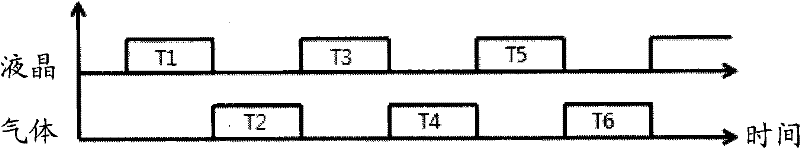

[0021] In the method for dropping liquid crystals according to a preferred embodiment of the present invention, liquid crystals are dropped, liquid crystals are introduced into LC supply paths, and liquid crystals are passed through nozzles by spraying gas toward liquid crystals forming liquid crystal droplets on nozzle ends.

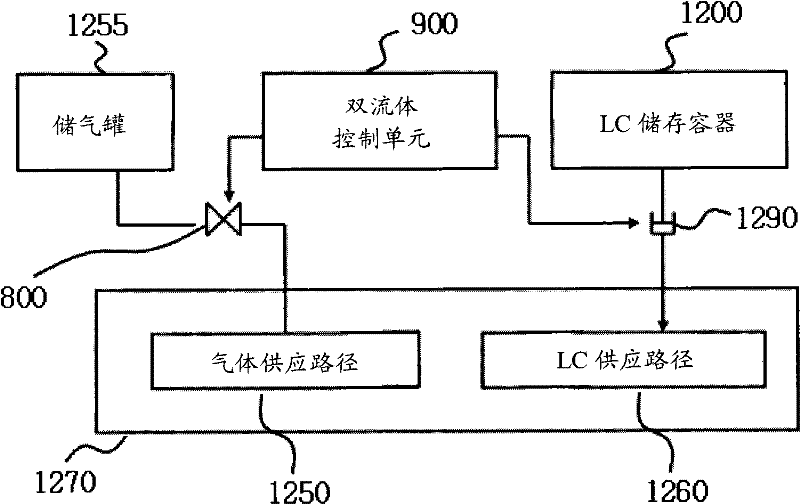

[0022] figure 2 is a block diagram showing a liquid crystal dispenser employing a method for dropping liquid crystals according to an embodiment of the present invention. like figure 2 As shown, the liquid crystal dispenser adopting the method for dripping liquid crystal according to the embodiment of the present invention includes a two-fluid control unit 900, a gas supply path 1250, a liquid crystal (LC) supply path 1260, a constant liquid crystal (LC) feeder 1290 and Gas regulating valve 800.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com