Liquid crystal display panel with fluid control wall

A liquid crystal display panel, flow control technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as defective, liquid crystal pollution display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

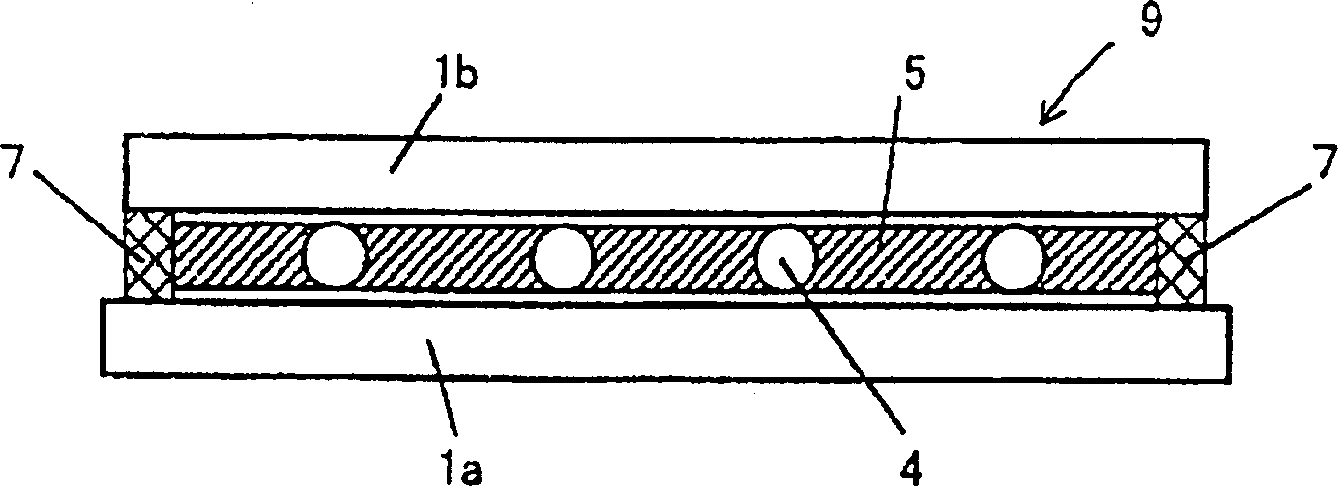

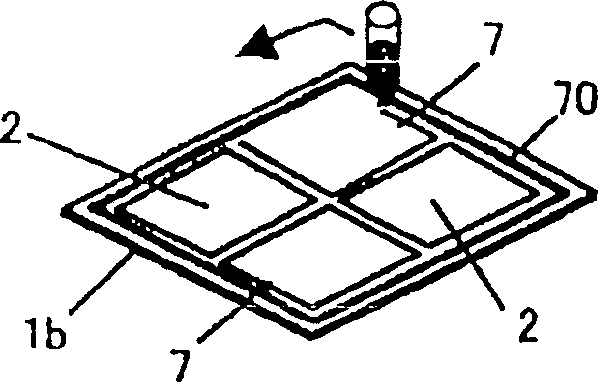

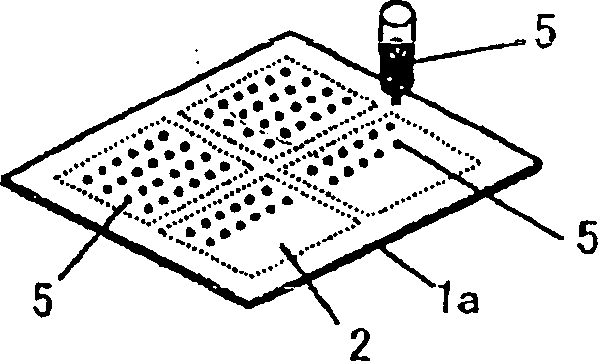

[0065] Hereinafter, embodiments of the liquid crystal display panel according to the present invention will be described in detail with reference to the accompanying drawings. 6A-6C are explanatory views of a first embodiment of a liquid crystal display panel according to the present invention. FIG. 6A is a perspective view of a TFT substrate, which is shown as an example of a case where four liquid crystal display panels are produced from a large-sized substrate 1 . Fig. 6B is a top view showing one sheet of the liquid crystal display panel shown in enlarged Fig. 6A, Figure 6C It is a cross-sectional view along line A-A of FIG. 6B.

[0066] FIG. 6A shows the positional relationship between the display area 2 of the four liquid crystal display panels 9, the sealing material 7, and the flow control wall 3. FIG. Each liquid crystal display panel 9 such as Figure 6C As shown, liquid crystal 5 is sandwiched between a pair of substrates, TFT substrate 1a and CF substrate 1b, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com