Composition for forming polymer-dispersed liquid crystal, polymer dispersed liquid crystal coating, and self-luminescent light-adjusting film

A technology for dispersing liquid crystals and compositions, applied in coatings, liquid crystal materials, optics, etc., can solve problems such as the inability to truly realize color changes, and achieve the effects of high open-state transmittance, good separation formability, and reversible color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of each layer of the dimming film provided by the present invention is as follows:

[0054] The transparent substrate layer and the transparent electrode layer adopt commercially available materials, and the transparent electrode layer is a well-known conductive layer for those skilled in the art, including but not limited to the nano-indium tin metal oxide conductive layer; the transparent substrate layer is a technology in the art The material of the transparent substrate known to personnel includes, but is not limited to, one of glass, polycarbonate, and polyethylene terephthalate.

[0055] The preparation method of the PDLC / electroluminescent color-changing layer is as follows: the PDLC / electroluminescent color-changing layer is prepared by the polymerization-induced phase separation method (PISP), which is to mix the prepolymer UV glue with the liquid crystal to form a homogeneous solution. Radiation polymerization or direct photoinitiated po...

Embodiment 1

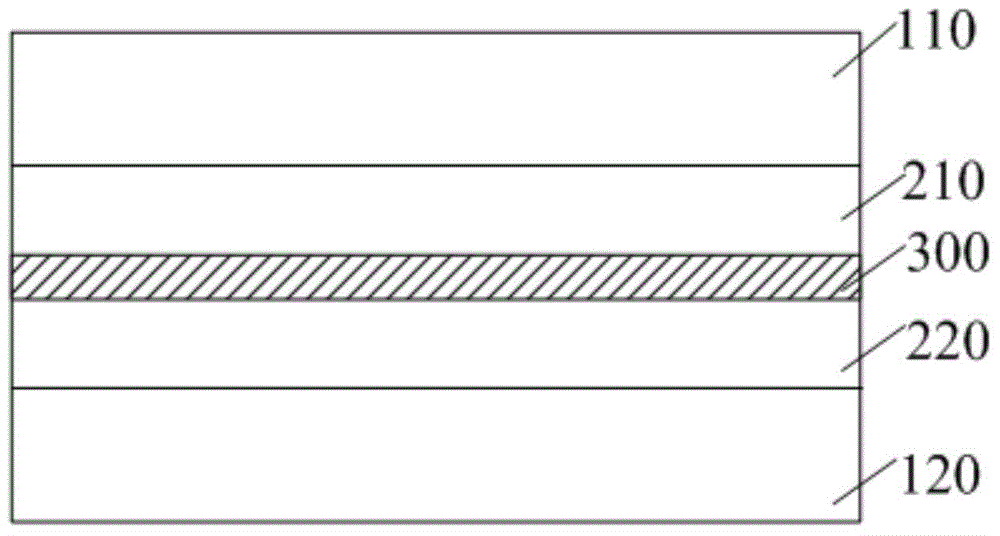

[0060] Such as figure 1 , the structure of the self-luminous dimming film in this embodiment is as follows from top to bottom: the first transparent substrate 110; the first transparent electrode 210; the polymer dispersed liquid crystal coating 300; the second transparent electrode 220; Material 120.

[0061] The composition of the PDLC composition is shown in Table 1; the light transmittance, haze, luminous color, and brightness properties of the self-luminous dimming film are shown in Table 2.

Embodiment 2

[0063] Such as figure 1 , the structure of the self-luminous dimming film in this embodiment is as follows from top to bottom: the first transparent substrate 110; the first transparent electrode 210; the polymer dispersed liquid crystal coating 300; the second transparent electrode 220; Material 120.

[0064] The composition of the PDLC composition is shown in Table 1; the light transmittance, haze, luminous color, and brightness properties of the self-luminous dimming film are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com