Method for improving color stability of compound wine

A wine preparation and stability technology, which is applied in the field of color stability control during the shelf life of prepared wine, can solve problems such as changes in wine body flavor components, and achieve the effects of stable wine body color difference value, gain shearing effect, and reduce the risk of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

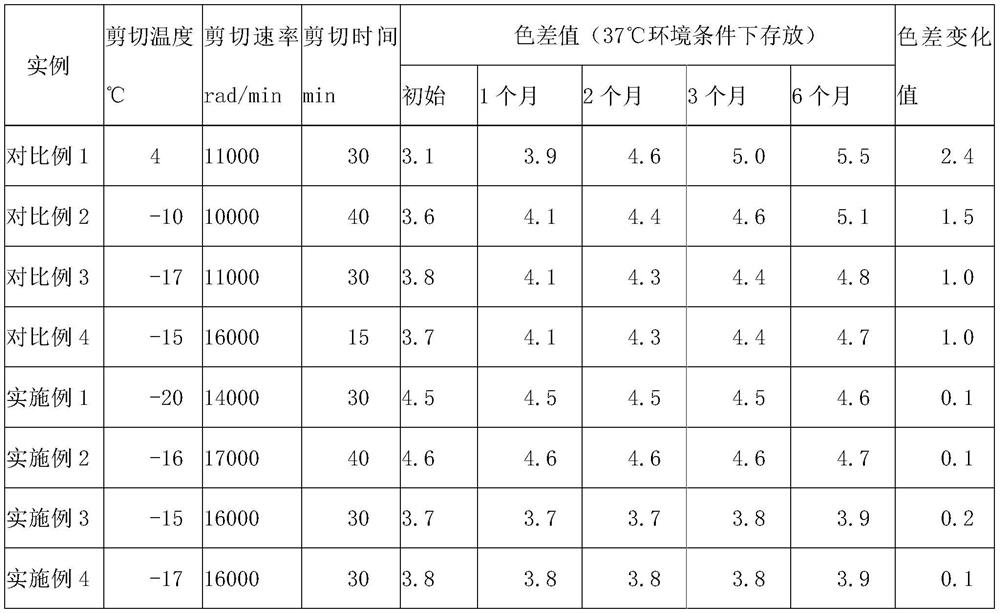

[0023] A method for improving the color stability of prepared wine, which consists of the following steps: through indirect heat exchange, the wine body added with tartary buckwheat extract is cooled to -16°C to -18°C, and a high-speed shear emulsifier is used to Shear the wine body at a speed of 12000rad / min to 18000rad / min for 30 minutes (intermittent completion). During the shearing process, the temperature of the wine body should not be lower than -15°C. After the shearing is completed, filter it while it is cold and fill it.

[0024] Through the color difference analyzer (ColorQuest XE), compare and track the change of the color difference value of the wine body at 37°C for 6 months, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com