Positive electrode active material for non-aqueous electrolyte secondary battery and manufacturing method thereof, and non-aqueous electrolyte secondary battery using same

A positive electrode active material and a non-aqueous electrolyte technology, which is applied to the positive electrode active material for non-aqueous electrolyte secondary battery and its preparation and the field of the non-aqueous electrolyte secondary battery, can solve the problems such as the reduction of the production efficiency of the positive electrode active material, Achieve the effect of reducing internal resistance, high life performance and stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

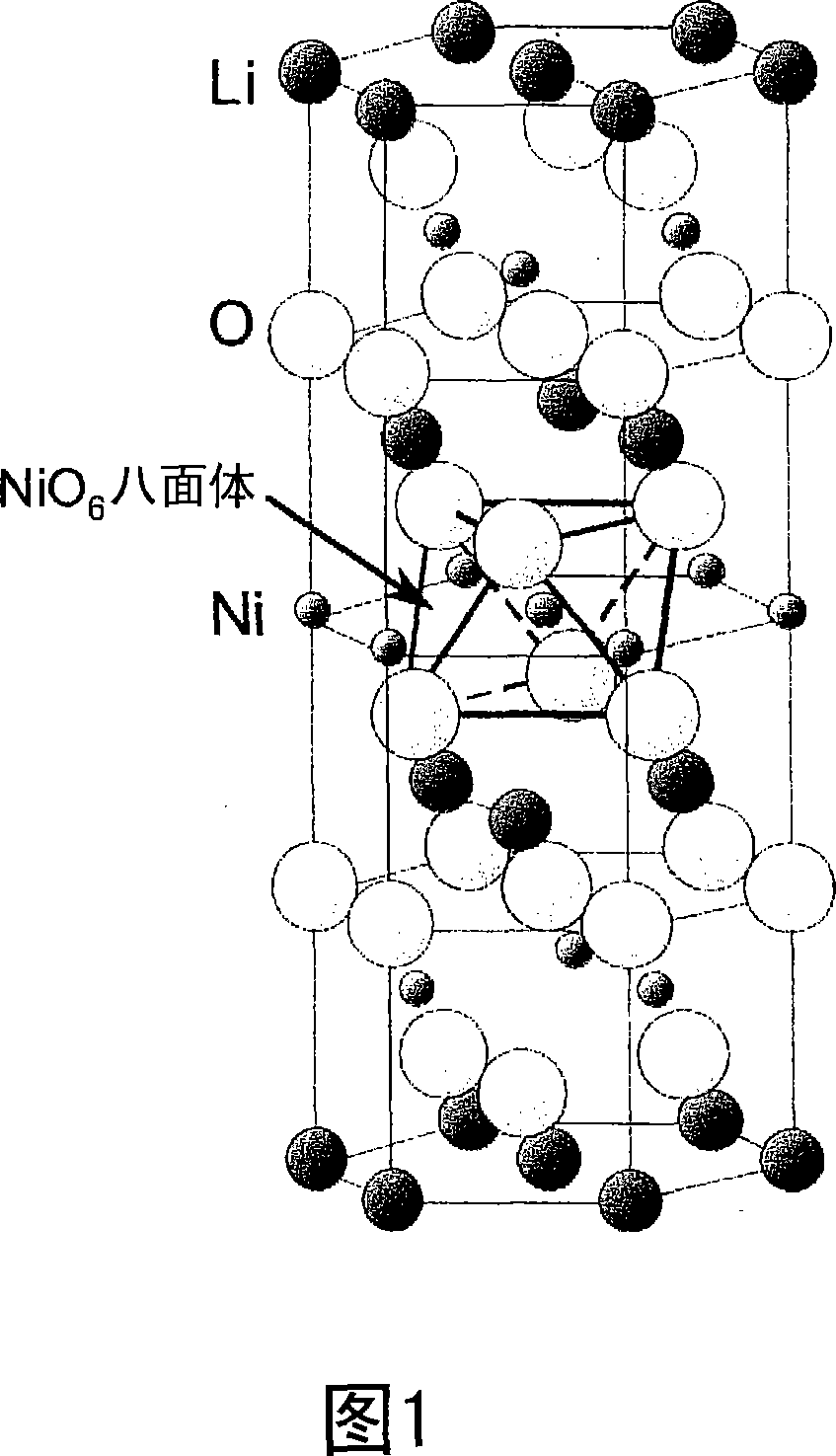

[0095] In LiNiO 2 In composite oxides, LiNi can be synthesized by substituting Co for 15at% Ni and Al for 3at% Ni 0.82 co 0.15 Al 0.03 o 2 . The at% herein means atomic %.

[0096] First, sodium hydroxide and ammonia are supplied to an aqueous solution in which nickel sulfate, cobalt sulfate and aluminum sulfate are dissolved, and a metal composite hydroxide is obtained by a co-precipitation method, wherein the molar ratio of nickel, cobalt and aluminum existing in the form of solid solution is 82:15:3. The metal composite hydroxide includes spherical secondary particles formed by aggregating a plurality of primary particles having a diameter of 1 μm or less. The tap density of obtained metal composite hydroxide is 1.72g / cm 3 .

[0097] Metal composite hydroxide and lithium hydroxide monohydrate (manufactured by FMC Corporation) for industrial use were weighed so that the ratio of the total number of moles of metals other than lithium (Ni, Co, and Al) to the number of ...

Embodiment 2

[0107] LiNi was synthesized by the same method as in Example 1 except that the main baking temperature was 750 °C 0.82 co 0.15 Al 0.03 o 2 . Table 1 shows the preparation conditions.

[0108] According to the X-ray diffraction analysis of the obtained baked product, it can be determined that this is an ideal positive electrode active material with a hexagonal layered structure. 95% or more of the particles of the obtained baked product had a particle size of 20 μm or less, with an average particle size of about 8.36 μm. In addition, the tap density of the obtained baked product was 2.34 g / cm 3 .

[0109] According to the same manner as in Example 1, Rietveld analysis, measurement of average compressive strength, measurement of average volume of pores having a diameter of 40 nm or less, and battery evaluation were performed. The results are shown in Table 2.

Embodiment 3

[0111] LiNi was synthesized by the same method as in Example 2, except that the holding time at the temporary baking temperature (450° C.) was 1 hour 0.82 co 0.15 Al0.03 o 2 . Table 1 shows the preparation conditions.

[0112] According to the X-ray diffraction analysis of the obtained baked product, it can be determined that this is an ideal positive electrode active material with a hexagonal layered structure. 95% or more of the particles of the obtained baked product had a particle diameter of 20 μm or less, and the average particle diameter was 8.43 μm. In addition, the tap density of the obtained baked product was 2.42 g / cm 3 .

[0113] According to the same manner as in Example 1, Rietveld analysis, measurement of average compressive strength, measurement of average volume of pores having a diameter of 40 nm or less, and battery evaluation were performed. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com