Reinforced test machine for rolling bearing life and reliability and its test method

A rolling bearing and reliability technology, which is applied in the field of enhanced test and rapid evaluation of rolling bearing life and reliability, can solve the problems of poor precision and stability, not suitable, low intelligence, etc., to improve bearing life performance and reasonable design , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

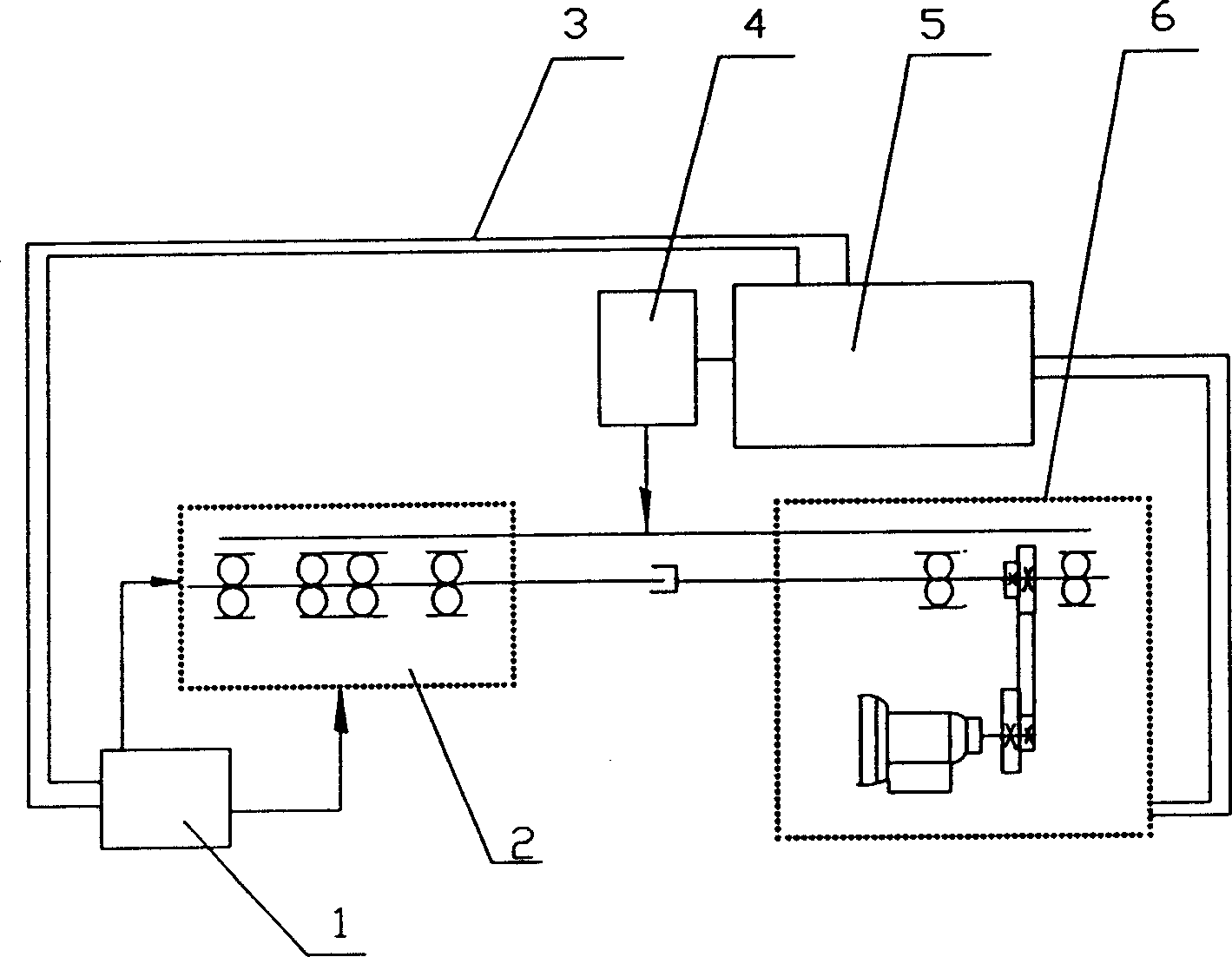

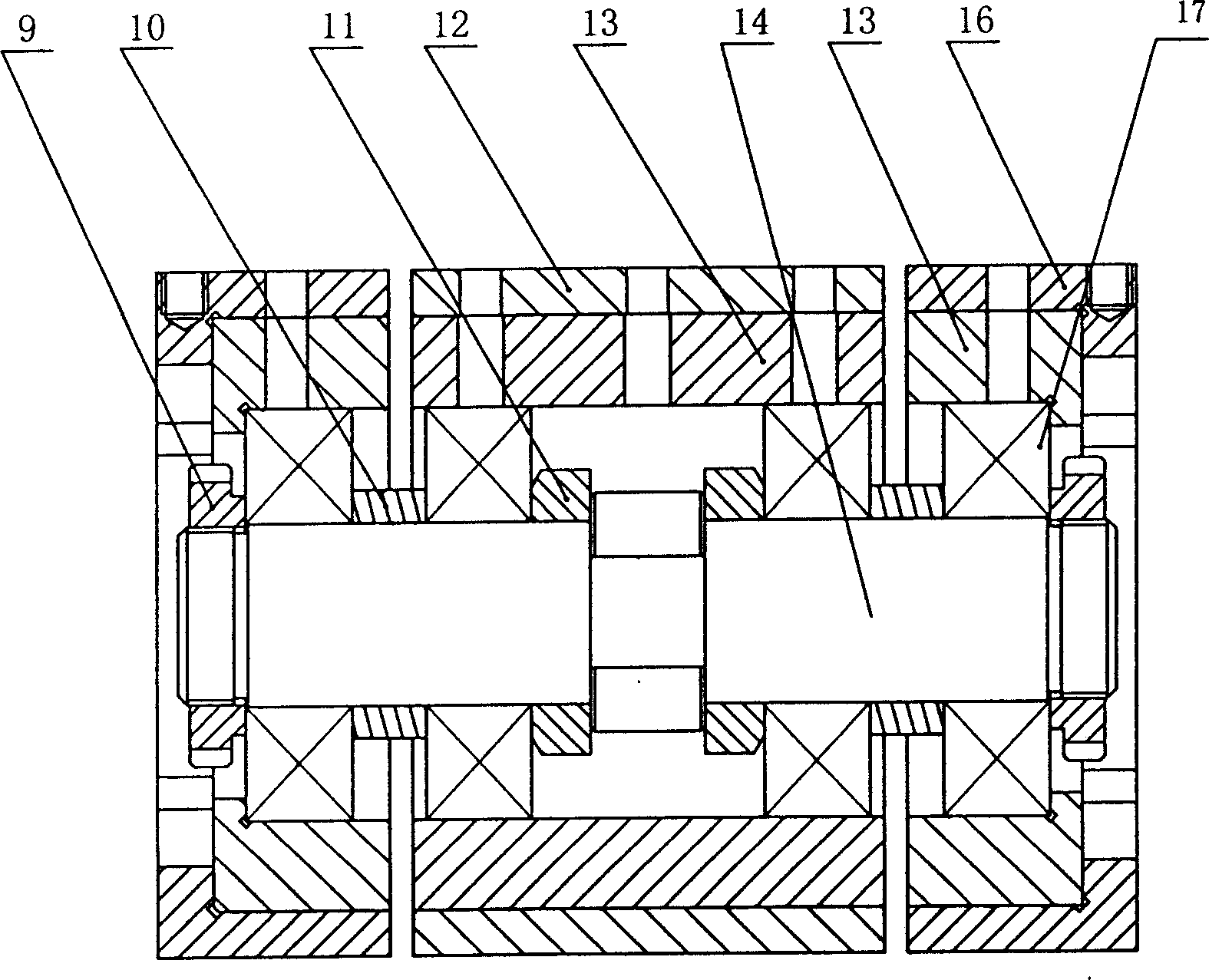

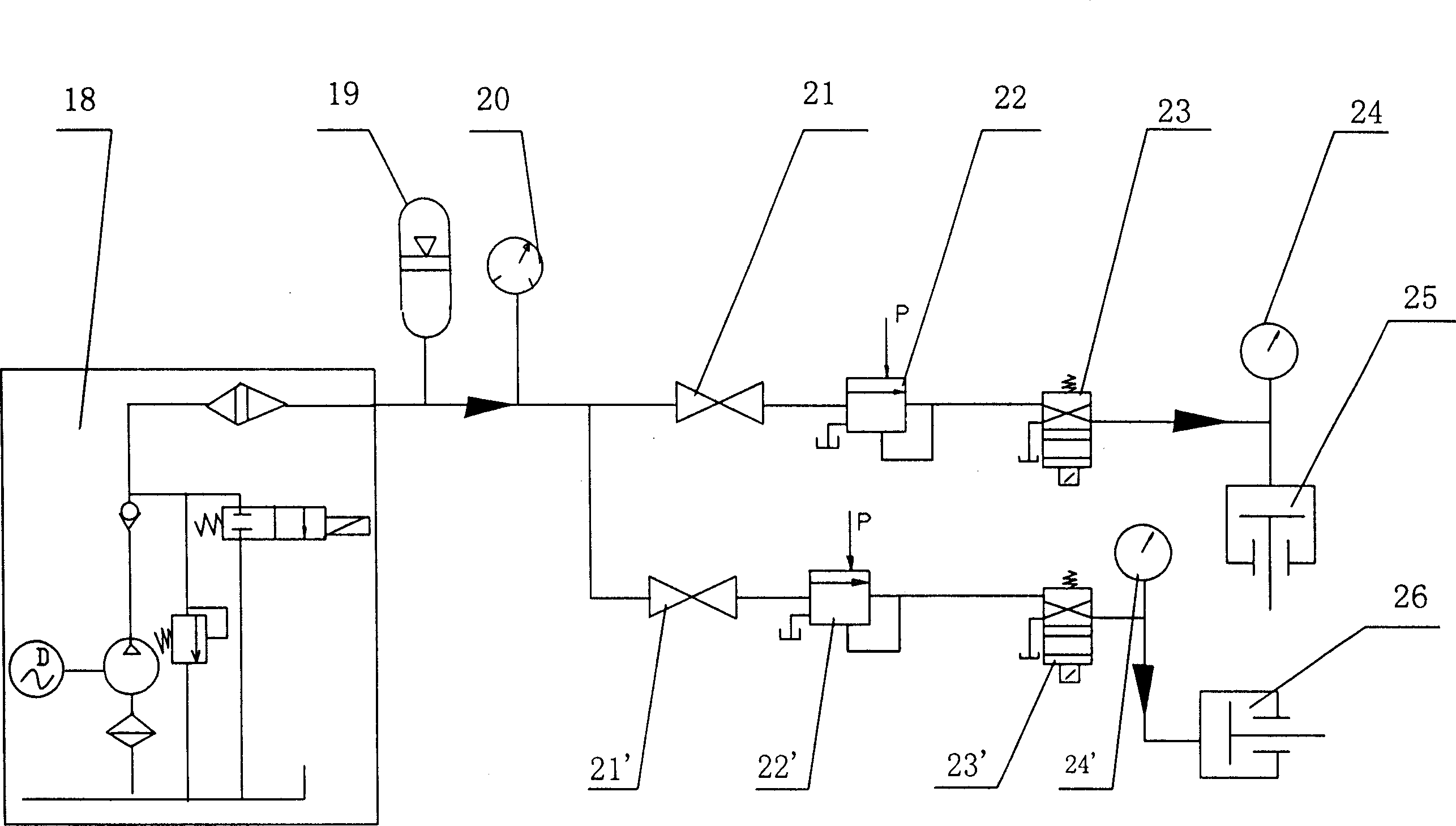

[0017] see figure 1 , figure 2 , the embodiment of the present invention rolling bearing life and reliability enhanced testing machine includes a loading mechanism 1, a test head part 2, a lubrication mechanism 4, a control system 5 (including an electrical control system, an industrial computer monitoring system) and a transmission mechanism 6, and the test head Part 2 is provided with a test head and a test head seat, the test head is installed in the test head seat, and the test head is provided with a lock nut 9, a spacer sleeve 10, a disassembly ring 11, a medium load body 12, a pad 13, a main shaft 14 and an end The load body 16, the lock nut 9, the spacer 10, the dismounting ring 11, the middle load body 12, the spacer 13, the end load body 16 and the test bearing 17 are all installed on the main shaft 14, and the spacer 10 separates the test bearing 17 and Keep it pre-tightened, the setting of dismounting ring 11 is beneficial to the dismounting of test bearing 17, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com