Method for manufacturing carbon-sulfur composite, carbon sulfur composite manufactured thereby, and electrochemical device including same

A composite, carbon-sulfur technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

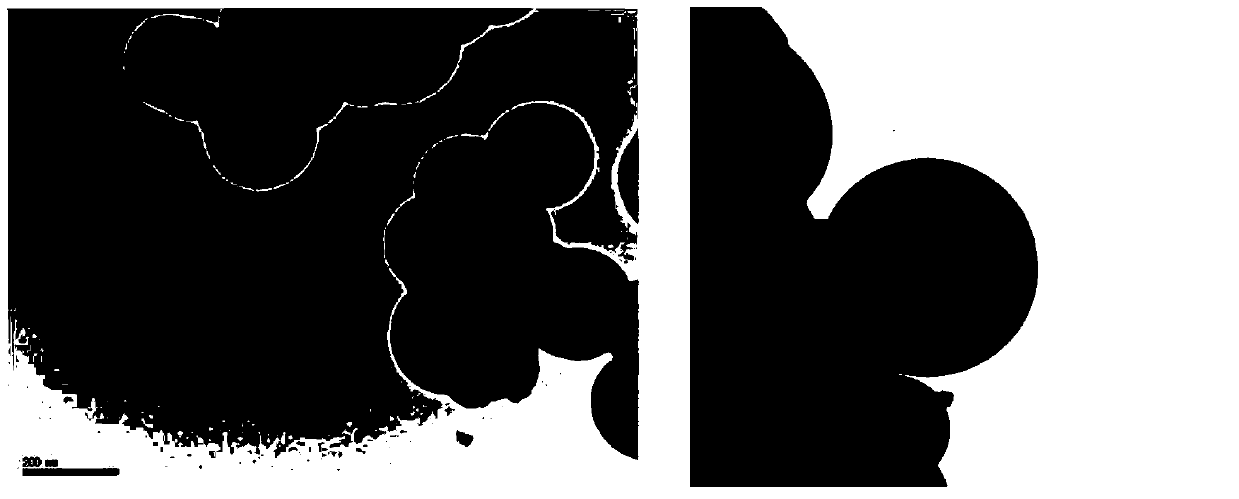

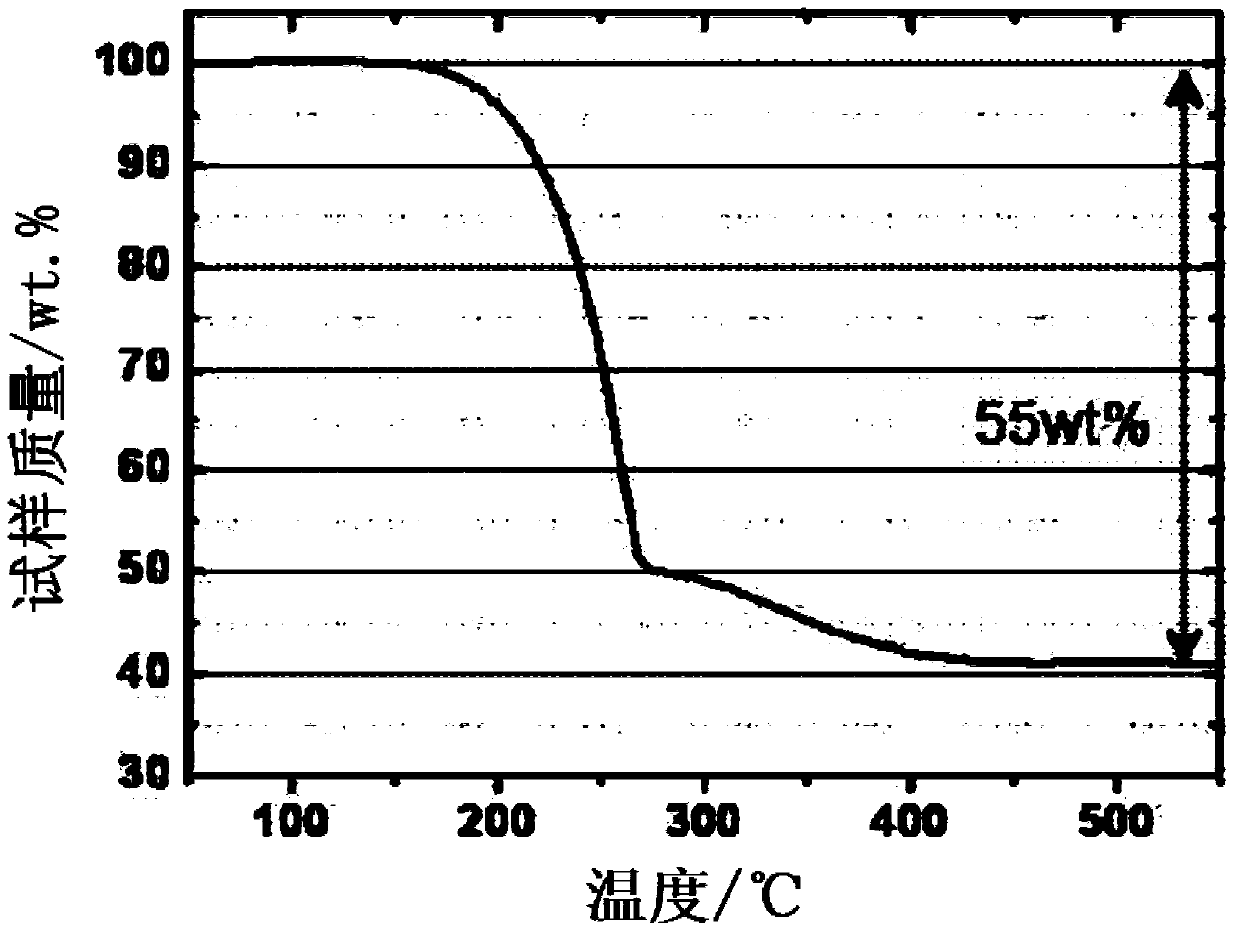

[0045] Preparation of carbon-sulfur complex

[0046] In order to fill the hollow carbon spheres with sulfur, the hollow carbon spheres obtained in Example 1 and sulfur were subjected to the first heat treatment at 600° C. for 4 hours in a Y-shaped glass tube in a vacuum state at a mass ratio of 1:5, Thus producing carbon-sulfur complexes.

Embodiment 3

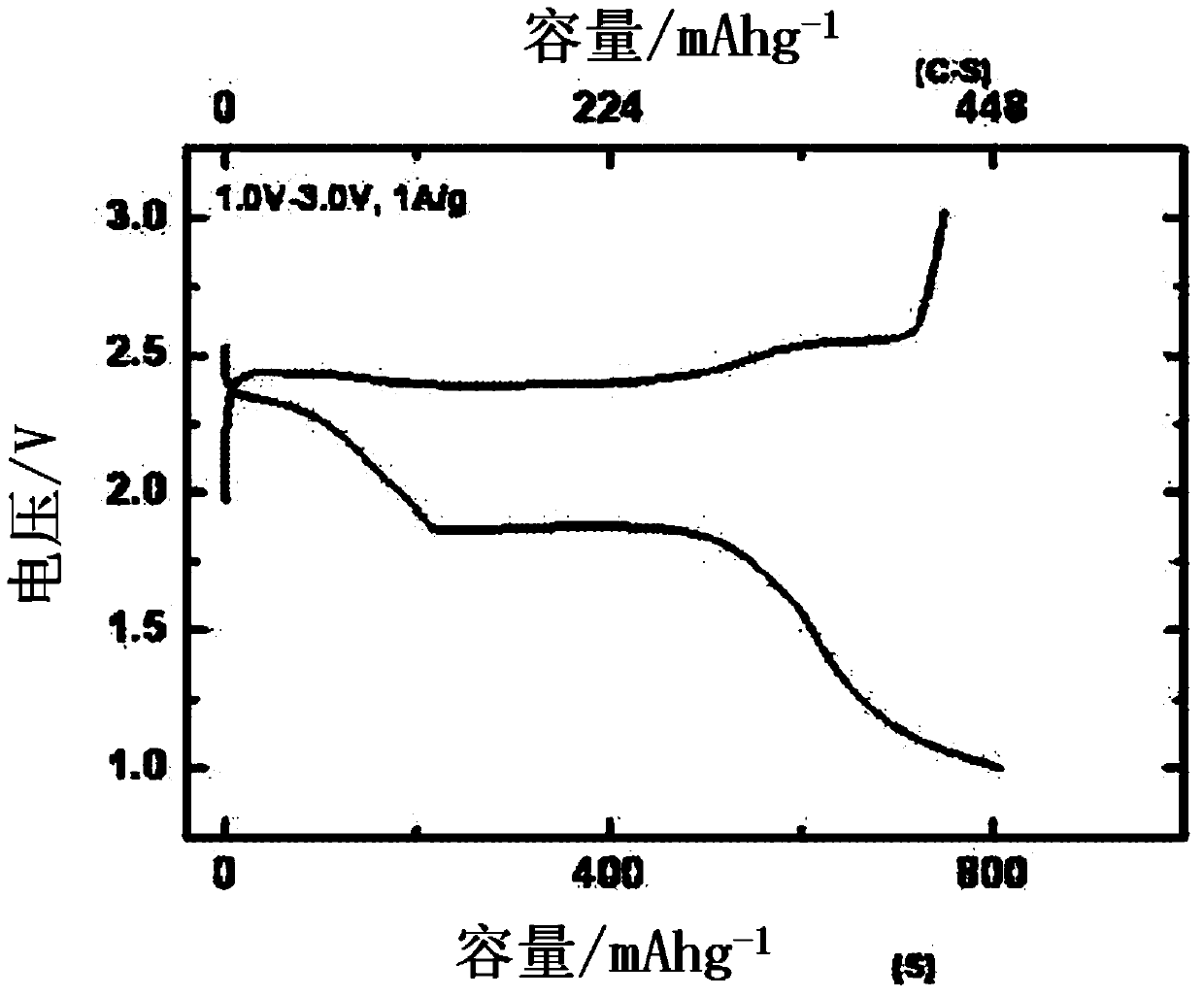

[0047] Preparation of electrodes and batteries

[0048] The carbon-sulfur composite prepared in Example 2-1, the carbon black conductive material and the polyethylene oxide binder were mixed in an acetonitrile solvent at a ratio of 60:20:20 to prepare a slurry. The prepared slurry was coated on aluminum foil to a thickness of 40 μm, rolled, and then dried at 50° C. to remove residual solvent.

[0049] A lithium-sulfur battery was fabricated using the obtained positive plate and lithium foil negative electrode. At this time, the LiSO 3 CF 3 A solution prepared by dissolving in tetraethylene glycol dimethyl ether (TEGDME) at a ratio of 4:1 was used as the electrolyte solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com