Preparation method for manganese dioxide-carbon nanotube-foamed nickel composite material capacitor electrode

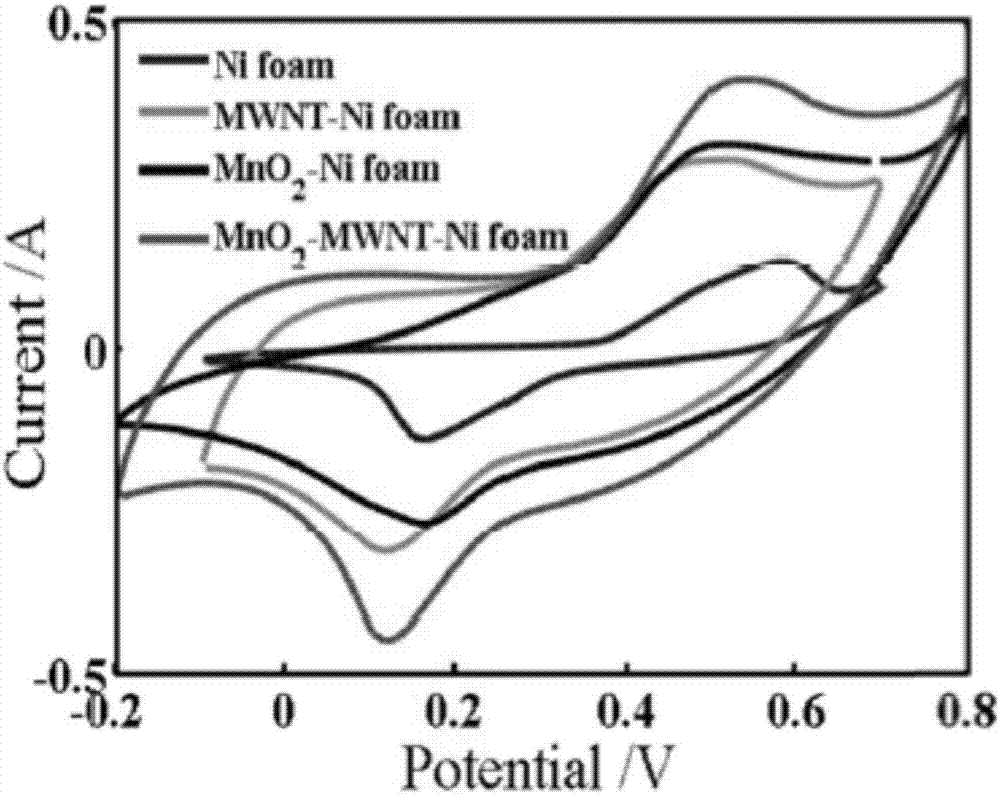

A composite capacitor and carbon nanotube technology, applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc. The problem of poor bonding between the composite material and the substrate can achieve the effect of excellent surface bonding performance, enhanced electrochemical and life performance, and significant technical advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

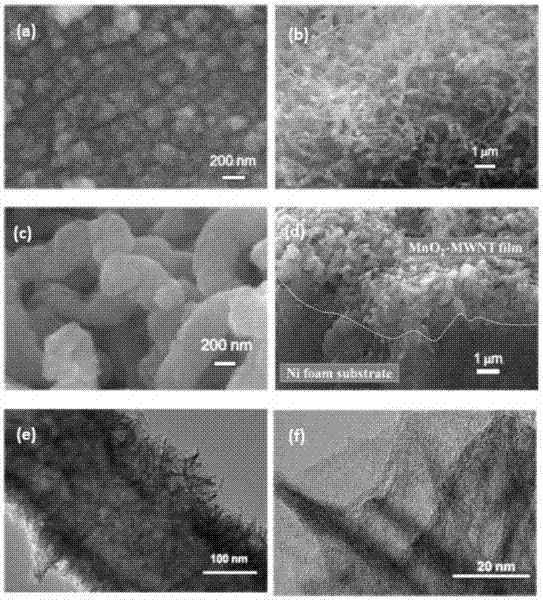

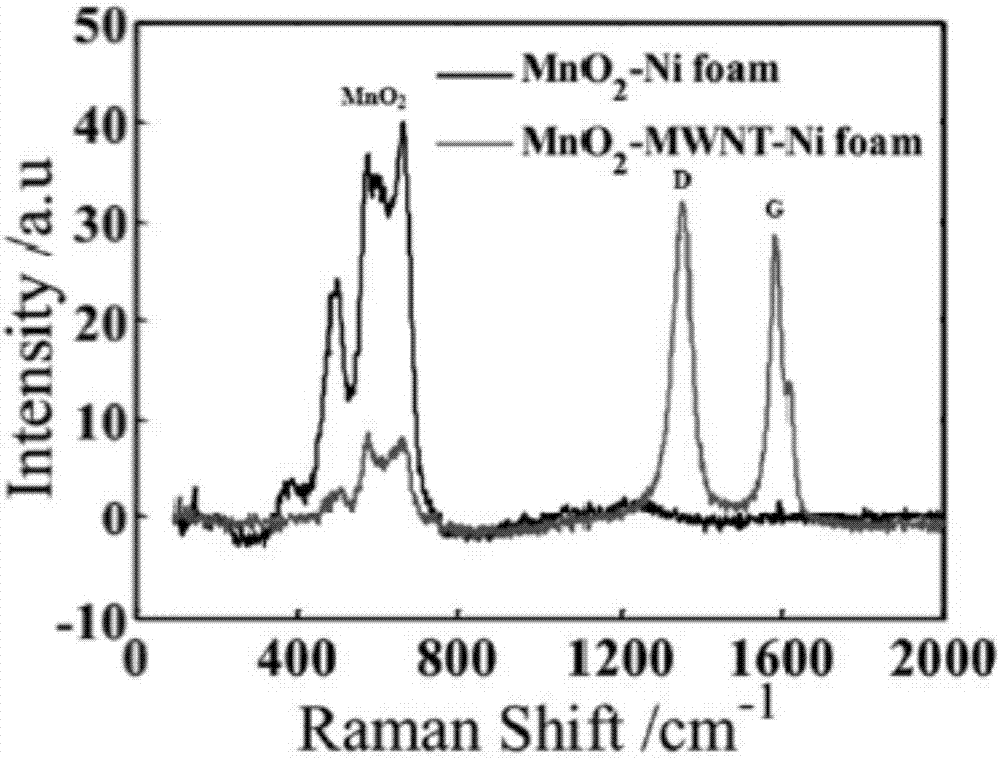

[0028] The first is to grow MWNTs on a nickel foam substrate. Choose 2.02.0 cm 2 After pre-cleaning, the foamed nickel substrate was anodized, and the specific conditions were: oxalic acid solution, anodizing voltage 10V, and time 5 minutes. After anodizing, it is washed with alcohol solution and deionized water successively. Then put the substrate in the CVD quartz reaction furnace, pass through C at 700 ℃ 2 H 2 / Ar mixed gas, after 10 min growth, the MWNT-nickel foam composite material was obtained. In the present invention, the parameters of the chemical vapor deposition can also be: carbon nanotube growth temperature 550 or 900°C, growth pressure 1 or 760 torr, gas flow ratio 10:400 or 40:100, and growth time 1 or 30 minutes. The argon is used as a carrier, and the carrier can also be nitrogen or hydrogen.

[0029] The second part is the hydrothermal synthesis of MnO 2 - MWNT - nickel foam composite capacitor electrodes. Specific step parameters include: configuring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com