Machining method for valve body, clamping clamp and machining equipment

A processing method and technology of processing equipment, used in metal processing equipment, manufacturing tools, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

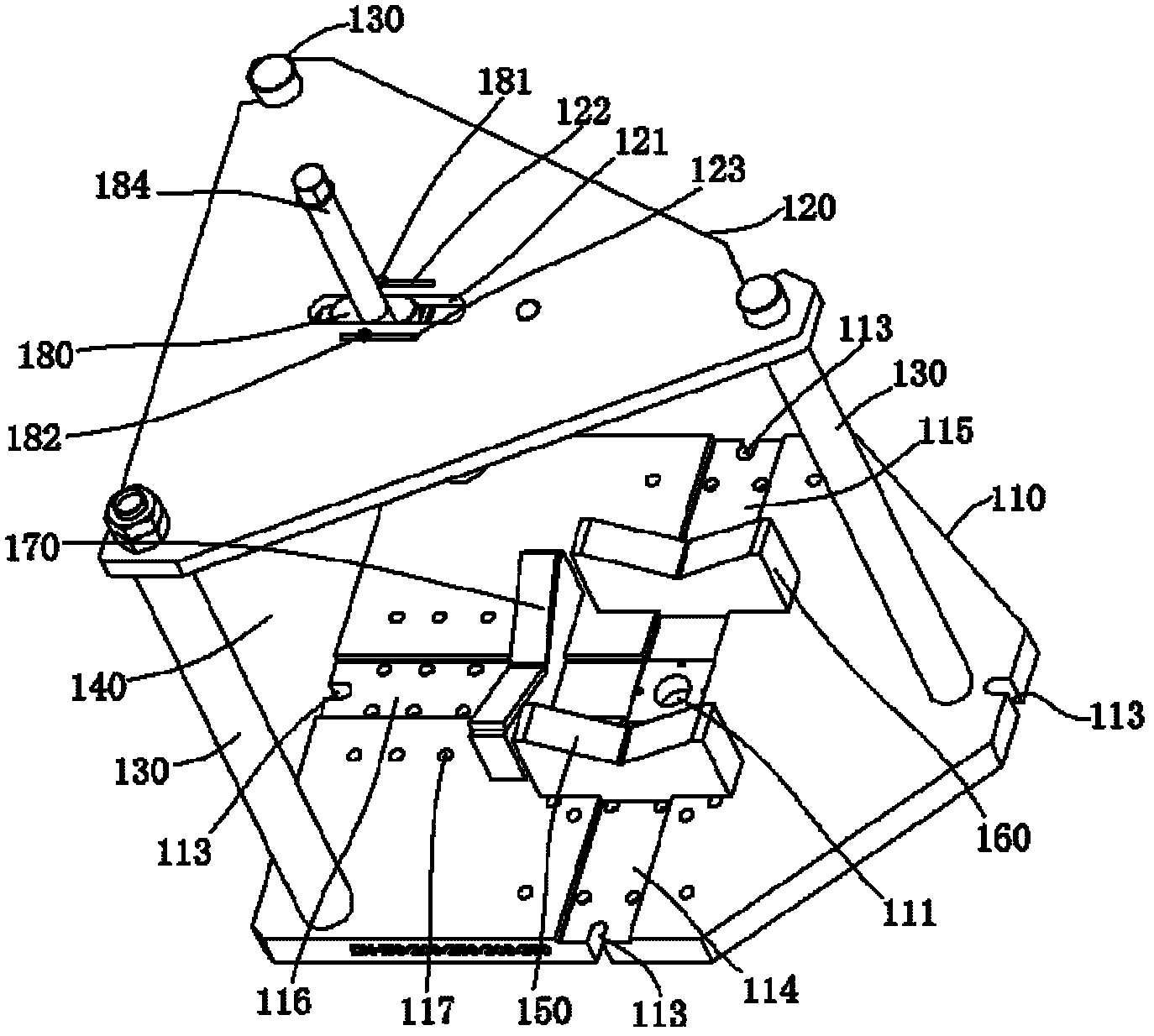

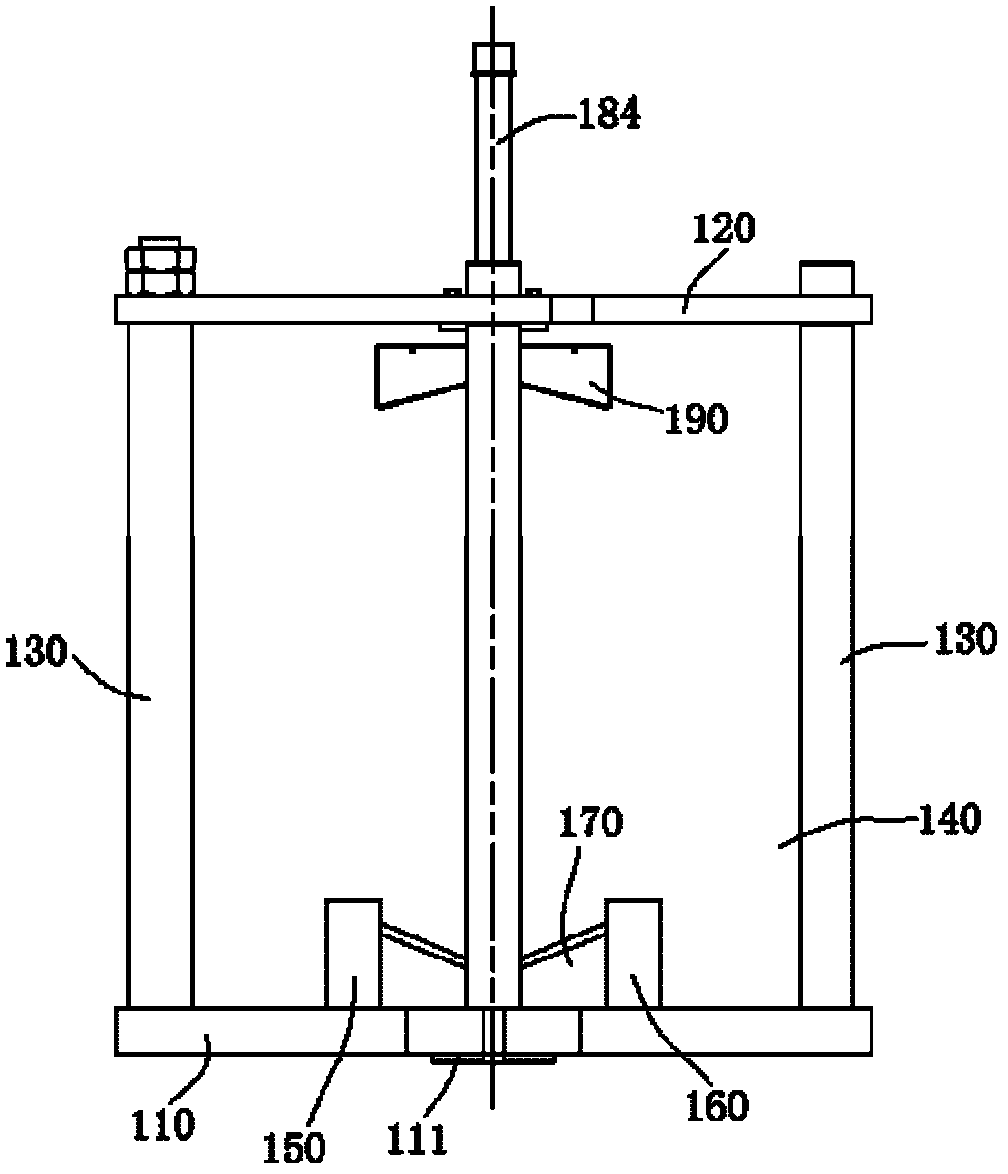

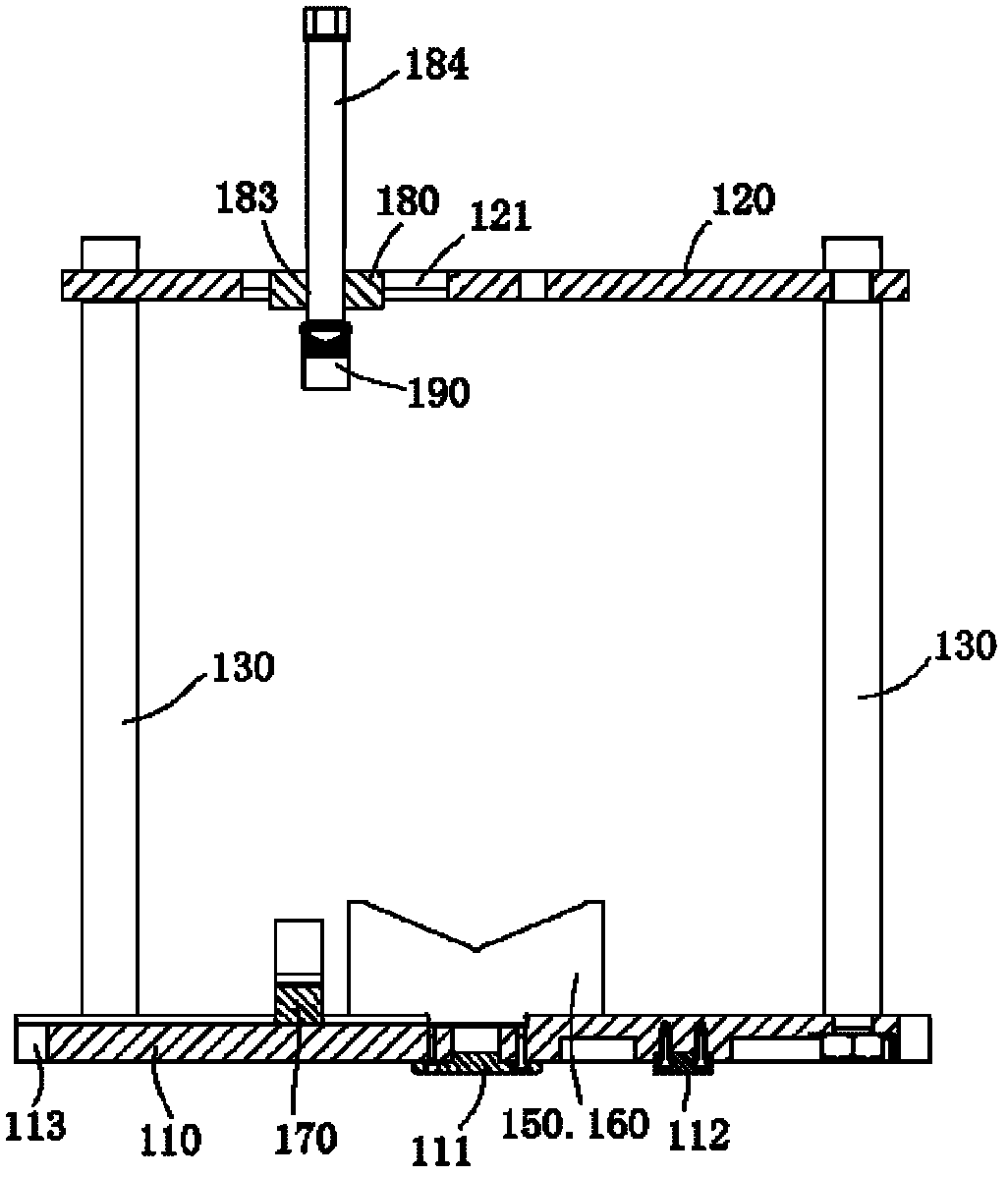

[0054] see Figure 1 to Figure 3 , the clamping fixture shown in the figure includes a bottom plate 110 and a top plate 120. The top plate 120 is installed on the bottom plate 110 through three rotating rods 130. Between the bottom plate 110 and the top plate 120, a multi-processing surface-type part that accommodates the same center of rotation is set. Space 140.

[0055]The bottom surface of the base plate 110 is provided with a central positioning block 111 cooperating with the central positioning hole of the rotary table, a positioning flat key 112 cooperating with the positioning groove on the rotary table, and several bolt opening slots 113 for clamping. On the front of the bottom plate 110, there are three T-shaped slots 114, 115, 116 radially distributed with the center of the center positioning block 111 as the center of the circle, and several T-shaped slots 114, 115, 116 are provided on both sides Bolt through hole 117; three T-shaped slots 114, 115, 116 are arrang...

Embodiment 2

[0058] see Figure 4 to Figure 6 The clamping fixture shown in the figure includes a rotating shaft 410, a pair of rigging parts 420, an I-beam part 430, a beam part 440, a disc jack assembly 450 and three V-shaped irons 460, 470, 480.

[0059] A rotating shaft positioning block 411 is fixed on the bottom of the rotating shaft 410, and the rotating shaft positioning block 411 is installed on the band end tooth positioning rotary table (not shown) by a T-shaped slot with a bolt 412 and a nut 413. A plurality of positioning holes 414 are arranged at intervals along the axial direction on the rotating shaft 410 .

[0060] The rotating shaft 410 and a pair of rigging parts 420 are arranged in a triangle on the rotary table with end teeth positioning to define a space 490 for accommodating the gate valve body 300; three V-shaped irons 460, 470, 480 are also used for T-shaped slots Bolts and nuts are installed on the rotary workbench with end tooth positioning. Three V-shaped irons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com