Material increasing and decreasing composite manufacturing equipment and method for metal parts

A technology of metal parts and additive manufacturing, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of rising manufacturing cost, prolonging production cycle, dimensional deviation, etc., and achieve low operation and maintenance costs, small size Excellent results in precision and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

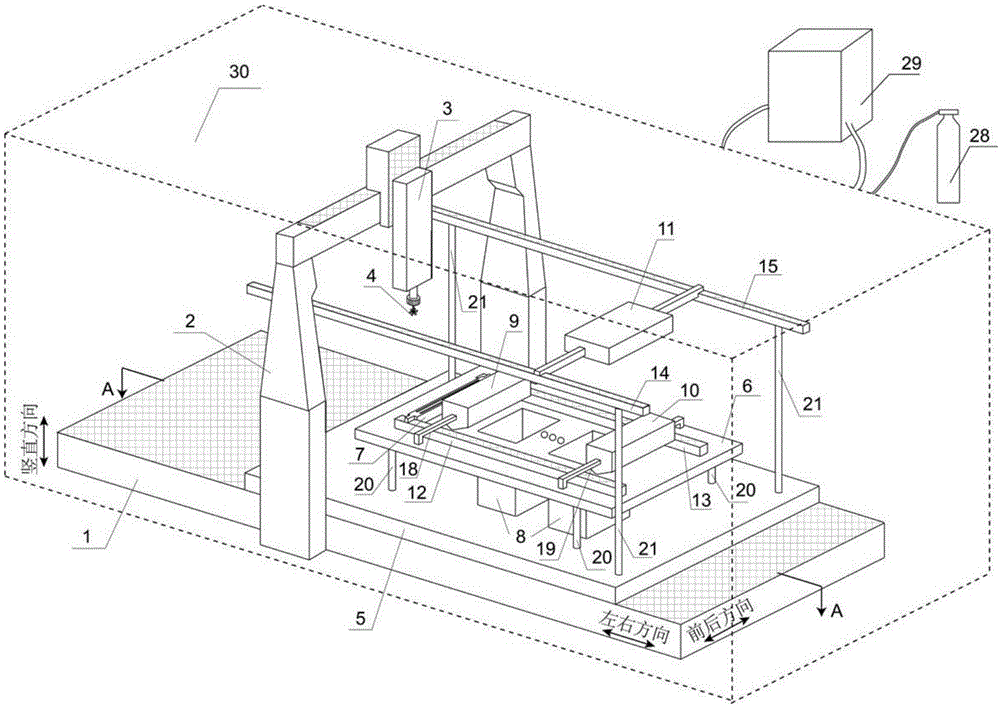

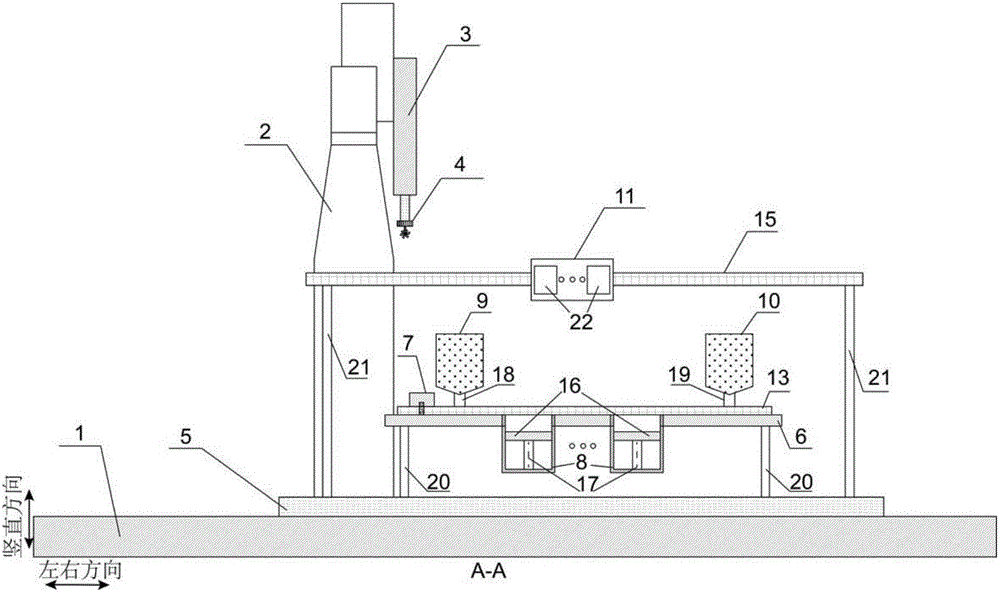

[0045] Such as figure 1 , figure 2 As shown, the example of the present invention provides an additive-subtractive composite manufacturing equipment for metal parts, including subtractive manufacturing components, additive manufacturing components, atmosphere control components and a control system.

[0046] The subtractive manufacturing assembly includes a milling tool 4 and a milling tool transmission system; the milling tool transmission system is specifically a five-axis linkage gantry machine tool, which is composed of a horizontal bed 1, a portal frame 2 and a boom 3; wherein, the door The vertical frame 2 spans the horizontal bed 1 that can be stretched in the left and right directions; the boom 3 is installed on the upper part of the portal frame 2 and can slide in the front, rear and vertical directions; the milling tool 4 is installed under the boom 3;

[0047]The additive manufacturing assembly includes a base 5, a working platform 6, a powder spreading device 7, ...

Embodiment 2

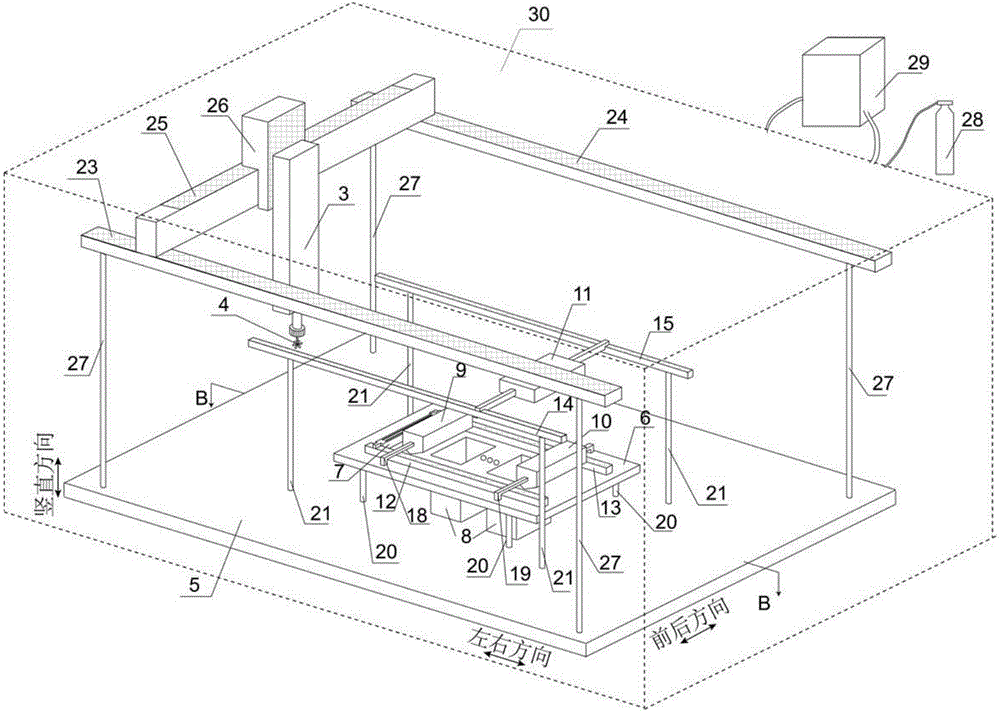

[0062] as shown in the picture image 3 , Figure 4 As shown, the example of the present invention provides an additive-subtractive composite manufacturing equipment for metal parts, including additive manufacturing components, subtractive manufacturing components, atmosphere control components and a control system.

[0063] The additive manufacturing assembly includes a base 5, a working platform 6, a powder spreading device 7, a forming cylinder 8, a first powder storage chamber 9, a second powder storage chamber 10, a laser scanning generator 11, and a first powder spreading guide rail 12 , the second powder spreading guide rail 13, the first scanning guide rail 14, the second scanning guide rail 15, the base plate 16, the piston 17, the first powder storage chamber support 18, the second powder storage chamber support 19, the working platform support column 20 and the scanning guide rail Support column 21; wherein, the base 5 is located at the bottom of the equipment; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com