Intelligent and numerical control system based on STEP-NC

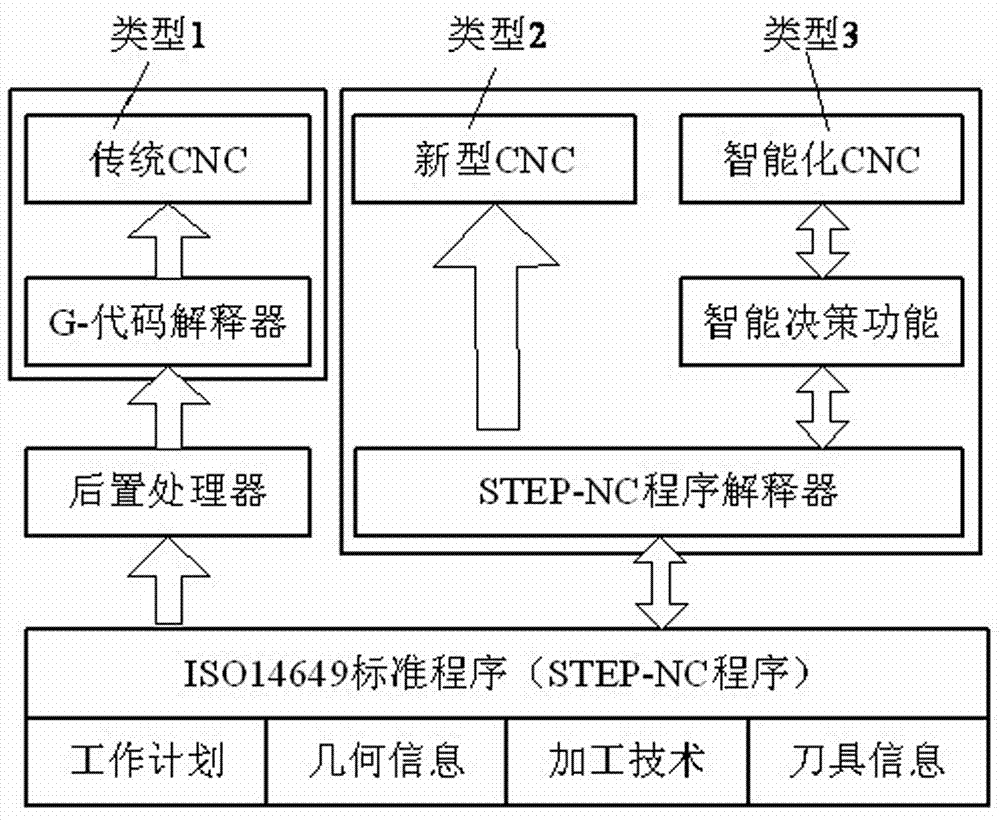

A STEP-NC, numerical control system technology, applied in general control system, control/regulation system, program control, etc., can solve the problems of difficult feedback of change information to the design department, poor surface quality, discontinuous feed speed and acceleration, etc. Achieve good interoperability and portability, reduced data preparation time, and reduced process planning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

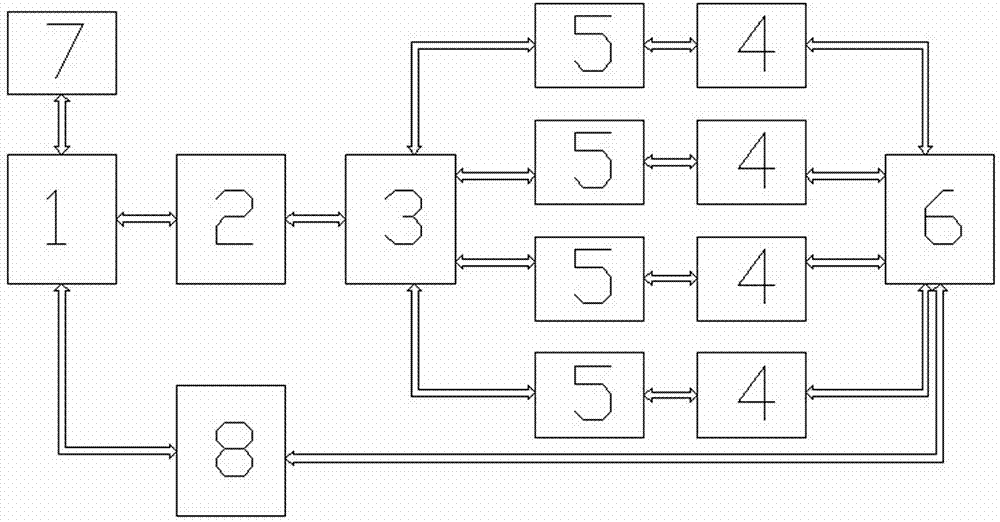

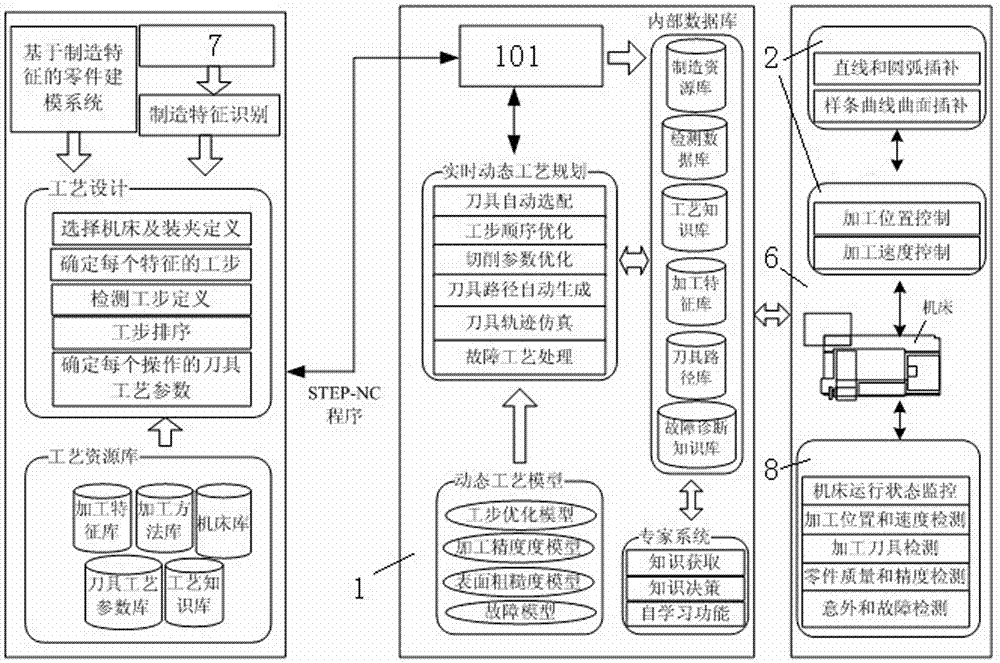

[0044] An intelligent numerical control system based on STEP-NC, connected and arranged on the machine tool body 6 (herein, the mechanical components in the machine tool and other detection and control components not directly related to the computer control device 1 are collectively referred to as the machine tool body 6) Together constitute an intelligent numerical control machine tool based on STEP-NC; the intelligent numerical control system based on STEP-NC is specifically composed of the following parts: computer control device 1, machine tool processing controller 2, driver 3, servo device 4, interface 5, Machine tool monitoring device 8; wherein: the machine tool processing controller 2 is connected with the computer control device 1 and the driver 3 respectively, and the driver 3 is also connected with the servo device 4 through the interface 5; the servo device 4 is connected and arranged on the machine tool body 6; the machine tool monitoring device 8 The computer con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com