Preparation method of nickel-cobalt-manganese ternary anode material

A cathode material, nickel-cobalt-manganese technology, which is applied in the field of preparation of nickel-cobalt-manganese ternary cathode materials, can solve the problems of small electric capacity and short life of cathode materials, and achieve easy industrialization, high electric capacity, and high first charge times. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

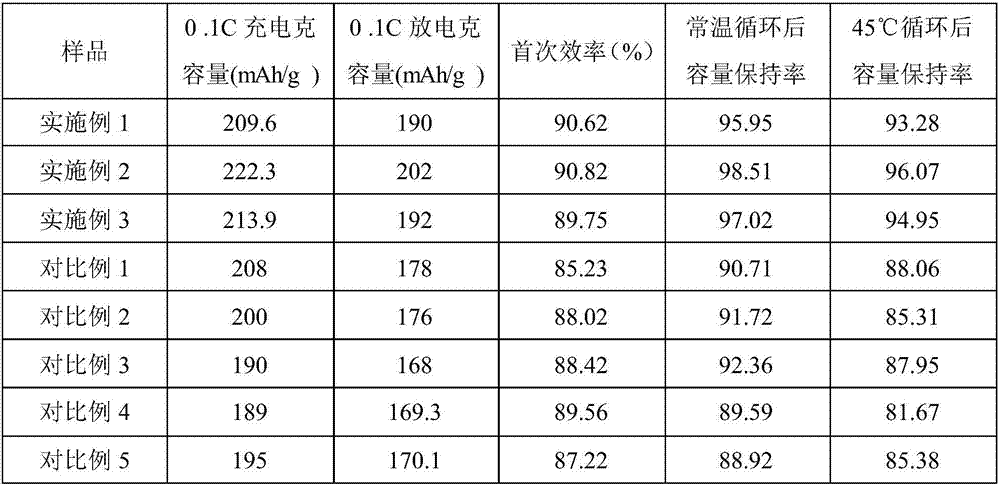

Embodiment 1

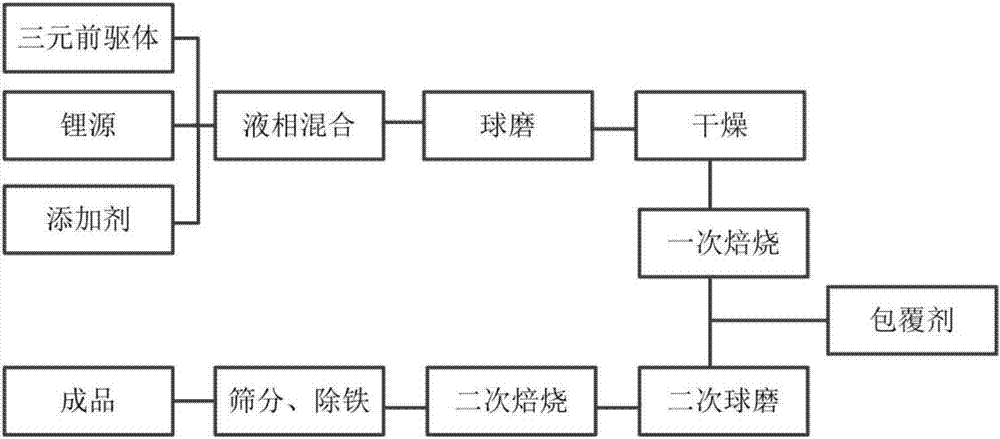

[0024] The preparation process of the nickel-cobalt-manganese ternary positive electrode material provided by the invention is as follows figure 1 As shown, the specific operation steps are:

[0025] Step A, raw material pretreatment: sieve the lithium hydroxide raw material through a 200-mesh sieve to obtain particles, and control the particle size D50 = 3-8 μm for later use;

[0026] Step B, pre-doping treatment: the lithium hydroxide raw material particles obtained in the step A, the ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 and Mg(NO 3 ) 2 Add distilled water and use a high-speed mixer for liquid phase mixing. After mixing evenly, the liquid phase mixture is directly ball milled for 1 hour. After ball milling, it is dried in a pan dryer at a temperature of 90°C to obtain a mixed powder; The molar ratio to (Ni+Co+Mn) is 1.1:1, Mg(NO 3 ) 2 The added mass is 0.1% of the theoretical product mass;

[0027] Step C, primary sintering: Carry out primary sintering of...

Embodiment 2

[0031] The preparation process of the nickel-cobalt-manganese ternary positive electrode material provided by the invention is as follows figure 1 As shown, the specific operation steps are:

[0032] Step A, raw material pretreatment: sieve the lithium hydroxide raw material through a 200-mesh sieve to obtain particles, and control the particle size D50 = 3-8 μm for later use;

[0033] Step B, pre-doping treatment: the lithium hydroxide raw material particles obtained in the step A, the ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 , Al(NO 3 ) 3 and NH 4 Add F into distilled water and use a high-speed mixer to carry out liquid phase mixing. After mixing evenly, the liquid phase mixture is directly ball milled for 3 hours. After ball milling, it is dried in a pan dryer at a temperature of 120°C to obtain a mixed powder; The molar ratio of Li to (Ni+Co+Mn) is 1.12:1, Al(NO 3 ) 3 The added mass is 0.6% of the theoretical product mass, NH 4 The added quality of F is 0....

Embodiment 3

[0038] Step A, raw material pretreatment: sieve the lithium hydroxide raw material through a 200-mesh sieve to obtain particles, and control the particle size D50 = 3-8 μm for later use;

[0039] Step B, pre-doping treatment: the lithium hydroxide raw material particles obtained in the step A, the ternary precursor LiNi 0.6 co 0.2 mn 0.2 (OH) 3 and Al(NO 3 ) 3 Add absolute ethanol and use a high-speed mixer to carry out liquid phase mixing. After mixing evenly, the liquid phase mixture is directly ball milled for 4 hours. After the ball milling, it is dried in a disc dryer at a temperature of 100°C to obtain a mixed powder; The molar ratio of Li to (Ni+Co+Mn) is 1.20:1, Al(NO 3 ) 3 The added mass is 0.8% of the theoretical product mass;

[0040] Step C, primary sintering: Carry out primary sintering of the mixed powder roller kiln obtained in the above step B, heat up at 10°C / min to 850°C for 5 hours, continuously feed oxygen during the sintering process, and the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com