Production process of spandex jacquard four-faced elastic fabric

A production process, four-way elastic technology, applied in the direction of digging fabrics, textiles, fabrics, etc., can solve the problems of poor moisture absorption, poor color fastness to perspiration, whitening, etc., and achieve the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

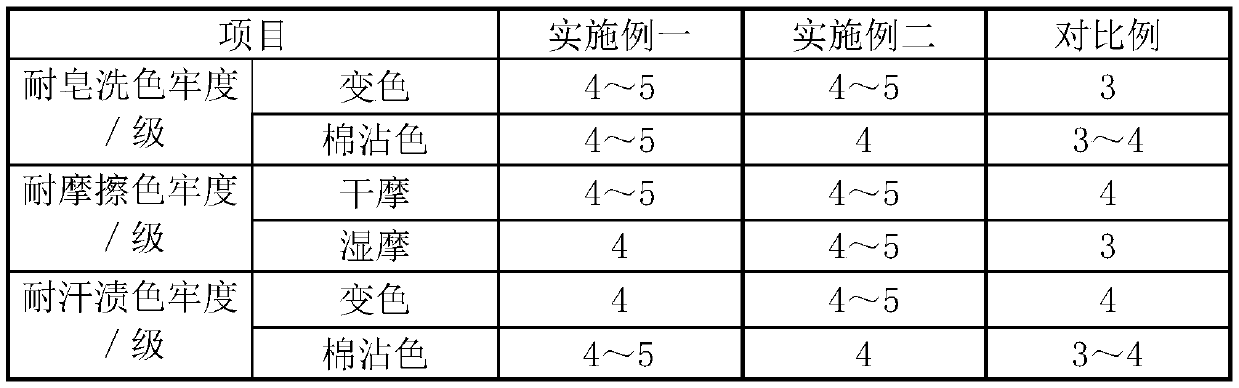

Examples

Embodiment 1

[0024] The production process of a spandex jacquard four-way stretch fabric involved in this embodiment comprises the following steps: Step A: preparation of polyester blank yarn, step B: preparation of warp yarn, step C: warping, step D: sizing, step E: weaving, Step F is desizing and dimensioning, step G is dyeing, and step H is setting.

[0025] In the preparation of step A polyester empty package yarn, the polyester filament DTY of 100D / 48F and the spandex empty package of 40D are used, the twist is 1100T / m, the twist direction is S, and the rebound machine used is Barmag FK6V- 1000, the disc is ceramic D type, Heberlein network nozzle, and the Unitens online tension monitoring system is used for tension monitoring; the speed of the texturing machine is 700m / min, the stretch ratio of polyester filament DTY is 1.27, and the stretch ratio of spandex is 3.5 , the false twist spindle group is 1-7-1, the D / Y ratio is 1.90; the temperature of the hot box is 168°C, the specificat...

Embodiment 2

[0036] The production process of a spandex jacquard four-way stretch fabric involved in this embodiment comprises the following steps: Step A: preparation of polyester blank yarn, step B: preparation of warp yarn, step C: warping, step D: sizing, step E: weaving, Step F is desizing and dimensioning, step G is dyeing, and step H is setting.

[0037] In the preparation of step A polyester empty package yarn, the polyester filament DTY of 100D / 48F and the spandex empty package of 40D are used, the twist is 1100T / m, the twist direction is S, and the rebound machine used is Barmag FK6V- 1000, the disc is ceramic D type, Heberlein network nozzle, and the Unitens online tension monitoring system is used for tension monitoring; the speed of the texturing machine is 750m / min, the stretch ratio of polyester filament DTY is 1.27, and the stretch ratio of spandex is 3.5 , the false twist spindle group is 1-7-1, the D / Y ratio is 1.90; the temperature of the hot box is 168°C, the specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com