Processing method for tomato juice mackerel can

A technology of mackerel in tomato sauce and a processing method, which is applied in the field of canned mackerel food processing, can solve the problems of discounted nutritional value and single taste of canned mackerel, and achieve the effect of delicious taste, nutritional value and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

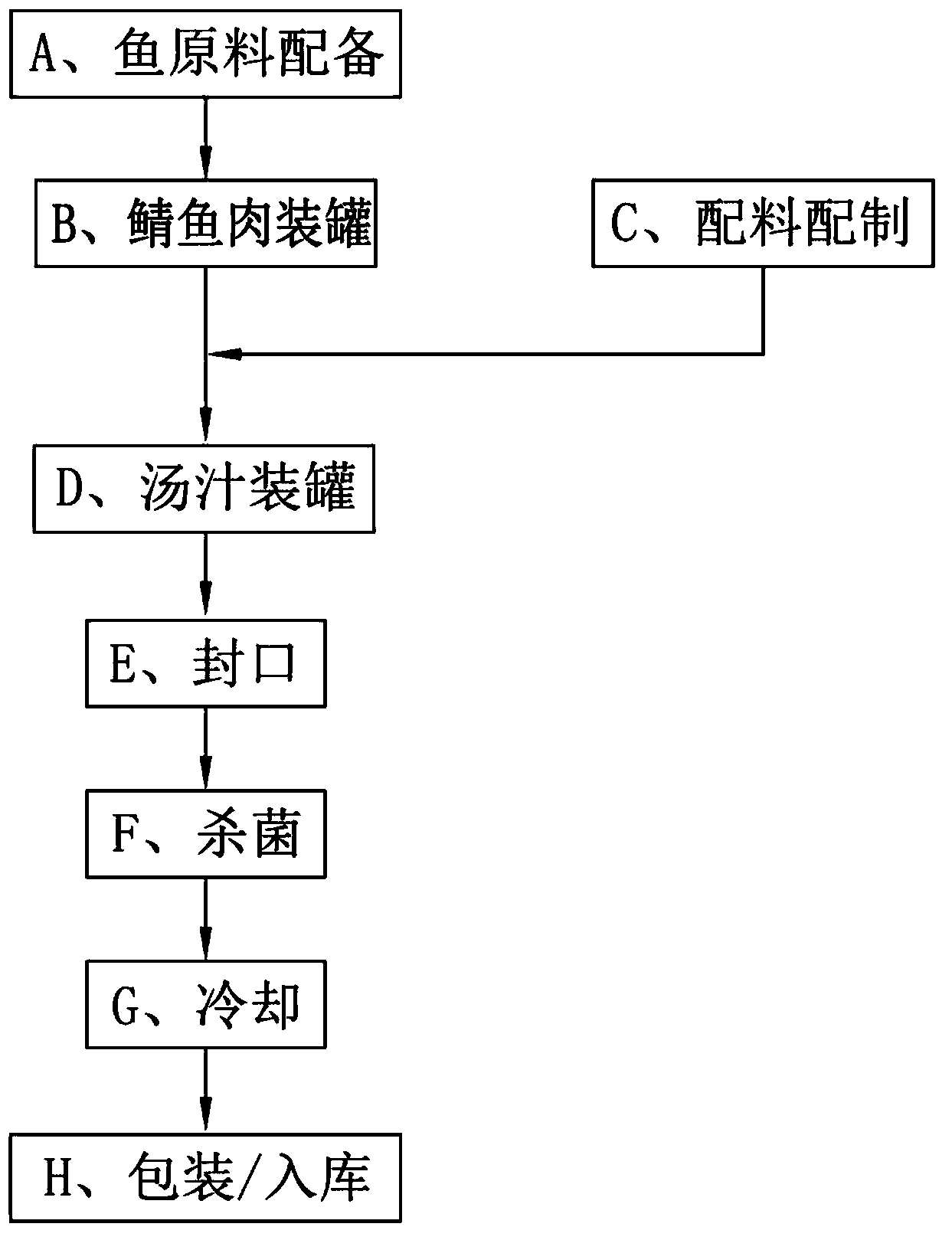

[0050] Example 1, see figure 1 Shown, a kind of processing method of canned mackerel in tomato sauce comprises the steps:

[0051] A. Fish raw material preparation-B, mackerel canning-C, ingredient preparation-D, soup canning-E, sealing-F, sterilization-G, cooling-H, packaging / warehousing, step C can be combined with step A Or step B is performed simultaneously.

[0052] Wherein step A, raw material fish are equipped with and comprise the following steps:

[0053] A1. Raw fish acceptance-A2, thawing-A3, cutting into sections-A4, cleaning-A5, salting-A6, draining-A7, and cleaning. It has high nutritional content and is suitable for the processing and production of canned mackerel food.

[0054] Wherein step F, sterilization comprises the following steps:

[0055] F1, solid tank cleaning-F2, stacking tank-F3, heat treatment or sterilization, the canned mackerel that has been sterilized through the above steps meets the relevant food safety requirements, and is safe and hygie...

Embodiment 2

[0089] Embodiment 2: the difference between this embodiment and embodiment 1 is that C, batching preparation, tomato juice canned mackerel soup is prepared according to the following weight ratio, tomato juice: 12%; Edible salt: 2%; White granulated sugar: 1% MSG: 1%; Soybean Oil: 2%; Onion: 3%; Xanthan Gum: 0.5%; Sodium Carboxymethyl Cellulose: 2%; The rest is cold water. The rest of the content is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0090] Embodiment 3: The difference between this embodiment and Embodiment 1 lies in C, ingredient preparation, tomato juice: 15%; edible salt: 4%; white granulated sugar: 3%; monosodium glutamate: 2%; soybean oil: 4%; 5%; Xanthan Gum: 1%; Sodium Carboxymethyl Cellulose: 3%; The rest is cold water. The rest of the content is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com