Comprehensive recycling method for lithium iron phosphate cathode material

A technology of lithium ferrous phosphate and cathode material, applied in recycling technology, phosphorus compounds, battery recycling, etc., can solve the problems of difficulty in ensuring product consistency, inability to meet lithium ferrous phosphate, etc., and solve the problem of resource recycling and utilization , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

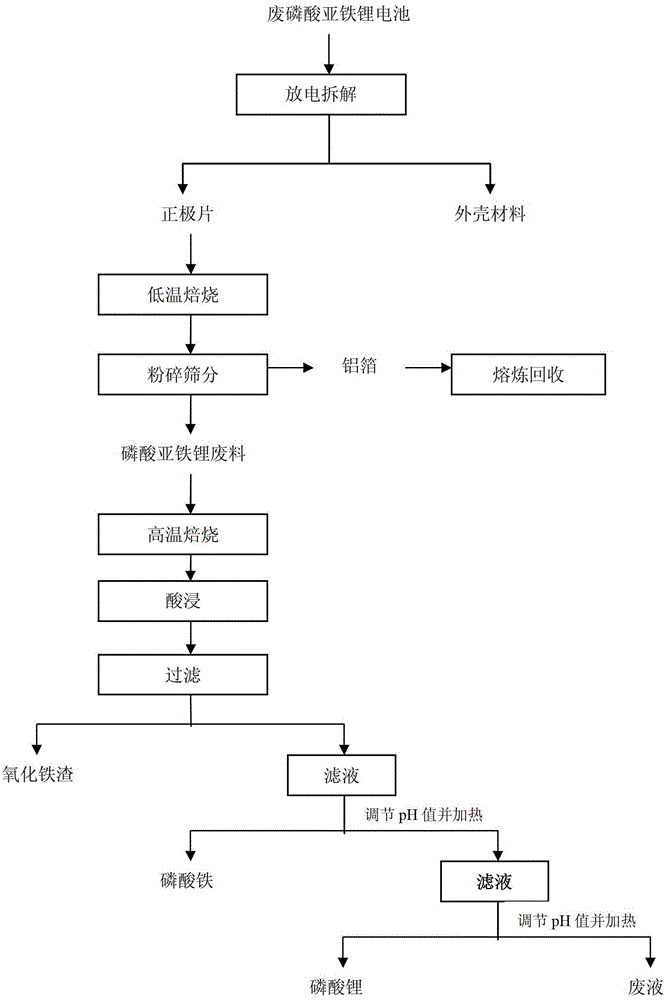

[0052] Embodiment 1 adopts the method of the present invention to comprehensively recycle and utilize lithium iron phosphate cathode material

[0053] Discharge the residual power of the waste lithium ferrous phosphate power battery, disassemble the battery, take out the positive electrode sheet, and recycle the battery shell according to the classification of aluminum shell, steel shell, plastic, etc.; roast the lithium iron phosphate positive electrode sheet at 400°C for 1 hour, crush it and sieve it Recycling positive electrode aluminum flakes; Obtain 100kg of lithium ferrous phosphate waste, lithium content 3.53%.

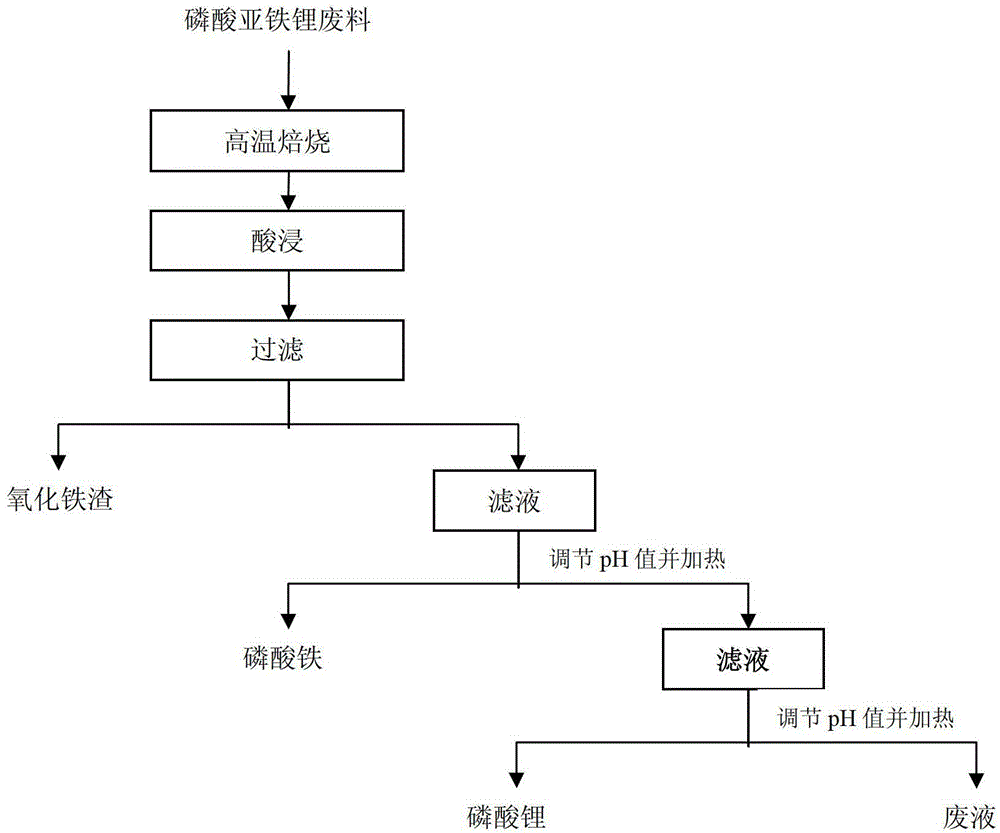

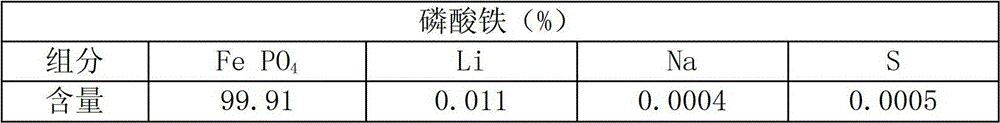

[0054] Roast lithium iron phosphate waste at 800°C for 1 hour, then add water to adjust the slurry, add 98% concentrated sulfuric acid to adjust the pH value to 0.5, filter to obtain a mixed solution of ferric phosphate, lithium phosphate, and ferric sulfate; heat the mixed solution to 80°C, add Alkali adjusted the pH value to 2.0, reacted for 4 hours, filtered...

Embodiment 2

[0060] Embodiment 2 adopts the method of the present invention to comprehensively recycle and utilize lithium iron phosphate cathode material

[0061] Get 100kg of lithium ferrous phosphate waste produced in the battery production process, with a lithium content of 3.51%. Roast lithium iron phosphate waste at 600°C for 2 hours, then add water to adjust the slurry, add 98% concentrated sulfuric acid to adjust the pH value to 0.8, filter to obtain a mixed solution of ferric phosphate, lithium phosphate, and ferric sulfate; heat the mixed solution to 90°C, add Alkali adjusted the pH value to 2.3, reacted for 2 hours, filtered to obtain crude iron phosphate, then washed with water at 60°C, and dried to obtain iron phosphate; the filtrate was adjusted to a pH value of 5, and then filtered to remove impurities; after removal of impurities, the filtrate was adjusted to a pH value of 11, React for 1 hour, filter to obtain crude lithium phosphate, wash with water at 60°C, and dry to ob...

Embodiment 3

[0067] Embodiment 3 adopts the method of the present invention to comprehensively recycle and utilize lithium ferrous phosphate cathode material

[0068] Get 100kg of lithium iron phosphate waste produced in the production process of lithium iron phosphate, and the lithium content is 4.39%. Roast lithium iron phosphate waste at 500°C for 4 hours, then add water to adjust the slurry, add 98% concentrated sulfuric acid to adjust the pH value to 1, filter to obtain a mixed solution of ferric phosphate, lithium phosphate, and ferric sulfate; heat the mixed solution to 100°C, add Alkali adjusted the pH value to 2.5, reacted for 1 hour, filtered to obtain crude iron phosphate, then washed with water at 80°C, and dried to obtain iron phosphate; the filtrate was adjusted to a pH value of 7, and then filtered to remove impurities; after removal of impurities, the filtrate was adjusted to a pH value of 10, React for 2 hours, filter to obtain crude lithium phosphate, wash with water at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com