Method for producing antibacterial fabric finished by bamboo vinegar liquor

A production method, antibacterial fabric technology, applied in the field of antibacterial fabric production, to achieve the effect of abundant resources, convenient use, and remarkable antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

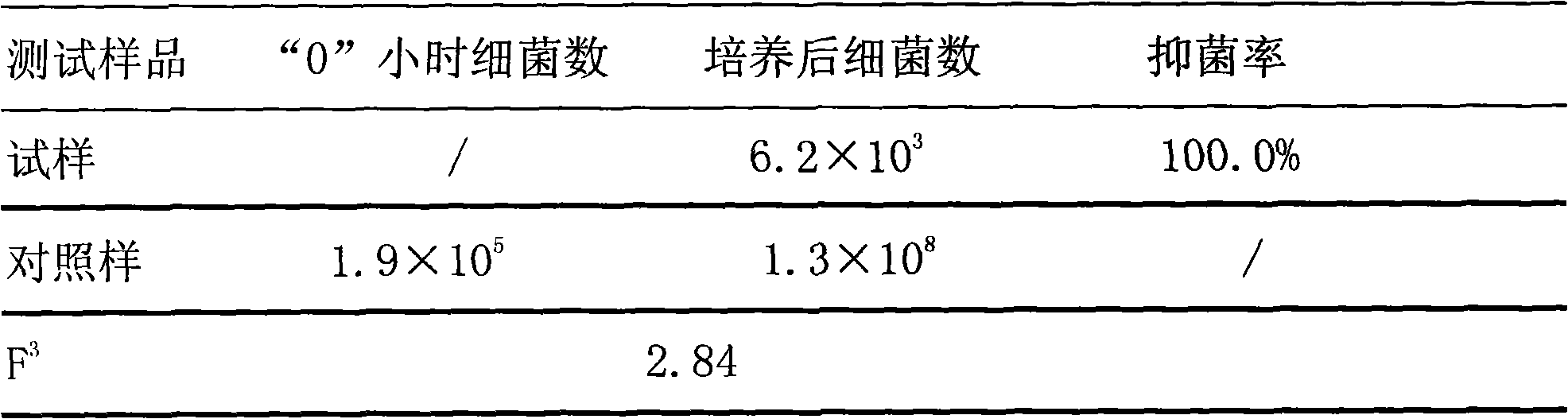

[0018] Embodiment 1, to the antibacterial finishing of silk fabric

[0019] a, firstly dry the silk fabric after cleaning;

[0020] B, be configured into 36 ℃ finishing liquid with clear water, wherein the added bamboo vinegar liquid and auxiliary agent concentration are by weight: bamboo vinegar liquid 2.2%, penetrating agent 0.3%, the rest is clear water, the finishing liquid is stirred evenly;

[0021] c. Put the finishing solution configured in step b into the bath of the drying equipment, and slowly pass the silk fabric through step a through the bath so that it is fully infiltrated by the finishing agent;

[0022] D, through the effect of roll through the silk fabric of c step, make the fabric rolling liquid rate be controlled at 72%;

[0023] e, the silk fabric through step d is pre-dried in a dryer, the temperature is 80°C, and the speed is 10m / min;

[0024] f. The silk fabric after step e is baked in a dryer at a temperature of 150° C. and a speed of 22 m / min.

Embodiment 2

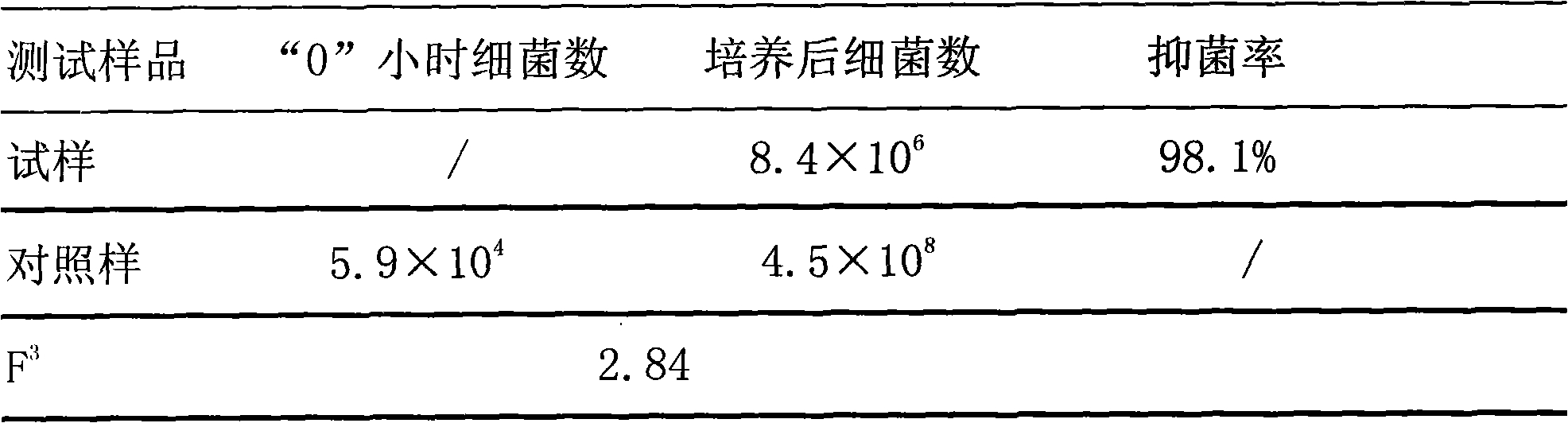

[0025] Example 2 Antibacterial finishing of yarn-dyed cotton

[0026] a. First, wash the yarn-dyed cotton cloth and then dry it;

[0027] b. Use clear water to configure a 45°C finishing solution, wherein the added bamboo vinegar and additive concentrations are by weight: bamboo vinegar 2.0%, penetrating agent 0.5%, softener 0.3%, and the rest is clear water, and the finishing solution is stirred Uniform;

[0028] c. Put the finishing solution configured in step b into the bath of the drying equipment, and slowly pass the yarn-dyed cotton cloth through step a through the bath to make it fully soaked by the finishing agent;

[0029] d, the yarn-dyed cotton cloth through step c passes through the effect of rolls, so that the fabric squeeze rate is controlled at 75%;

[0030] e. The yarn-dyed cotton cloth after step d is pre-dried in a dryer at a temperature of 85°C and a speed of 12m / min;

[0031] f. The yarn-dyed cotton cloth after step e is baked in a dryer at a temperature...

Embodiment 3

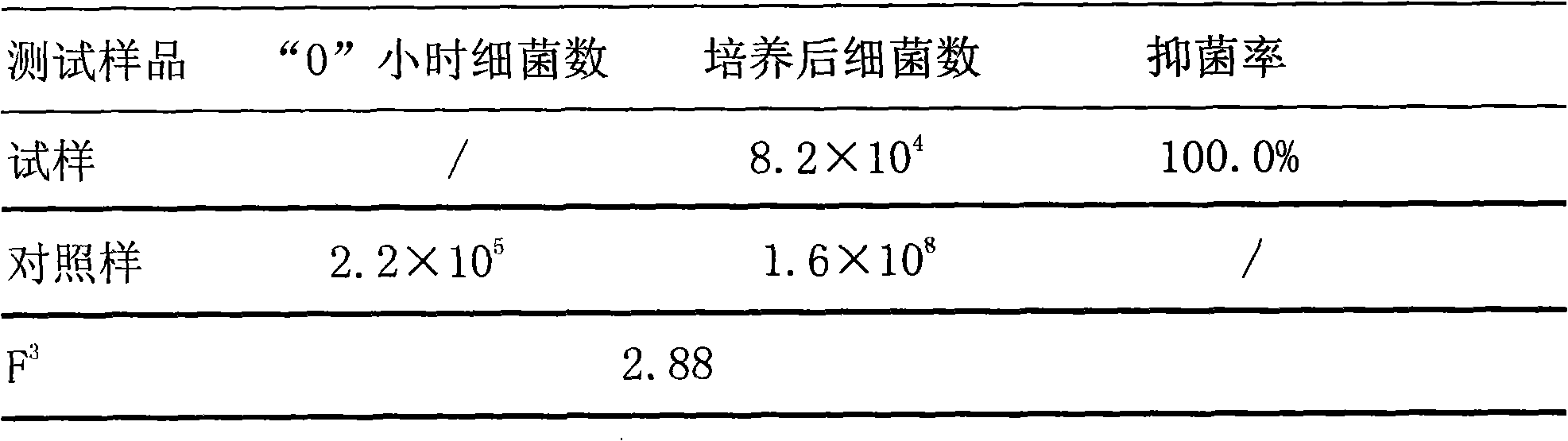

[0032] Embodiment 3, to the antibacterial finishing of bamboo charcoal polyester fiber / pearl fiber blended interweaving fabric

[0033] a. First, wash and dry the bamboo charcoal polyester fiber / pearl fiber blended fabric;

[0034] B, be configured into 40 ℃ finishing liquid with clear water, wherein the added bamboo vinegar liquid and auxiliary agent concentration are by weight: bamboo vinegar liquid 2.5%, softening agent 0.2%, the rest is clear water, the finishing liquid is stirred evenly;

[0035] c. Put the finishing solution configured in step b into the bath of the drying equipment, and slowly pass the fabric after step a through the bath to make it fully soaked by the finishing agent;

[0036] d, through the action of rolls on the fabric after step c, the liquid rolling rate of the fabric is controlled at 72%;

[0037] e. The fabric after step d is pre-dried in the dryer at a temperature of 85°C and a speed of 11m / min;

[0038] f. The fabric after step e is baked in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com