Non-linear process industrial fault prediction and identification method based on compressed sensing and DROS-ELM

A compressed sensing and fault prediction technology, applied in neural learning methods, instruments, biological neural network models, etc., can solve problems such as loss of life and property, and achieve the effect of improving production efficiency, increasing economic benefits, and having fewer adjustable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

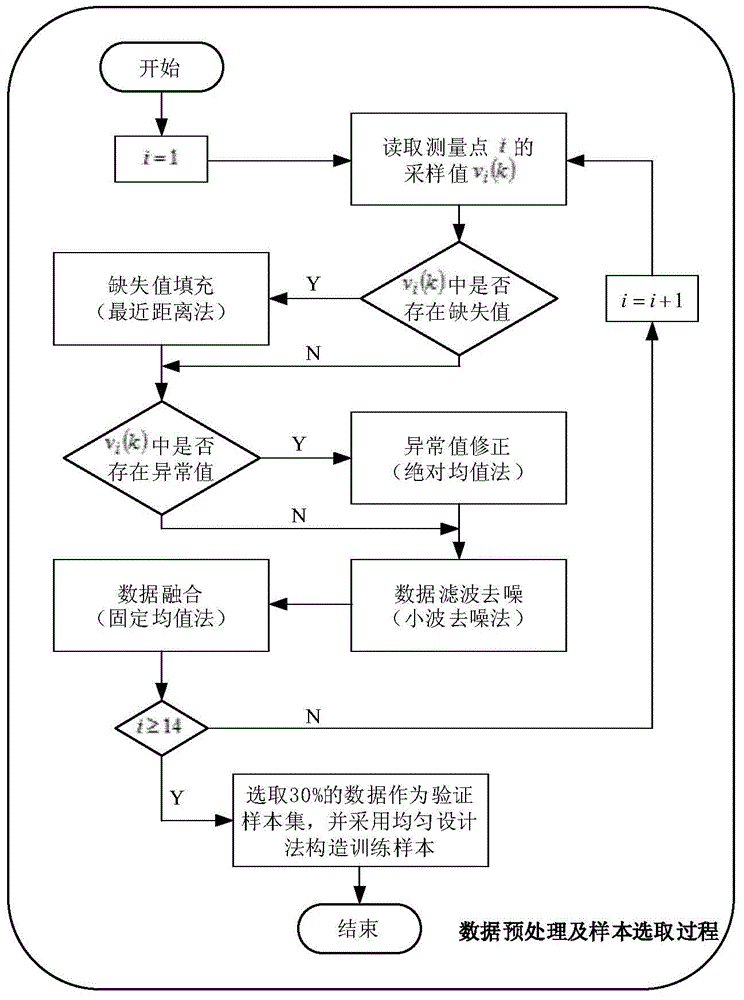

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

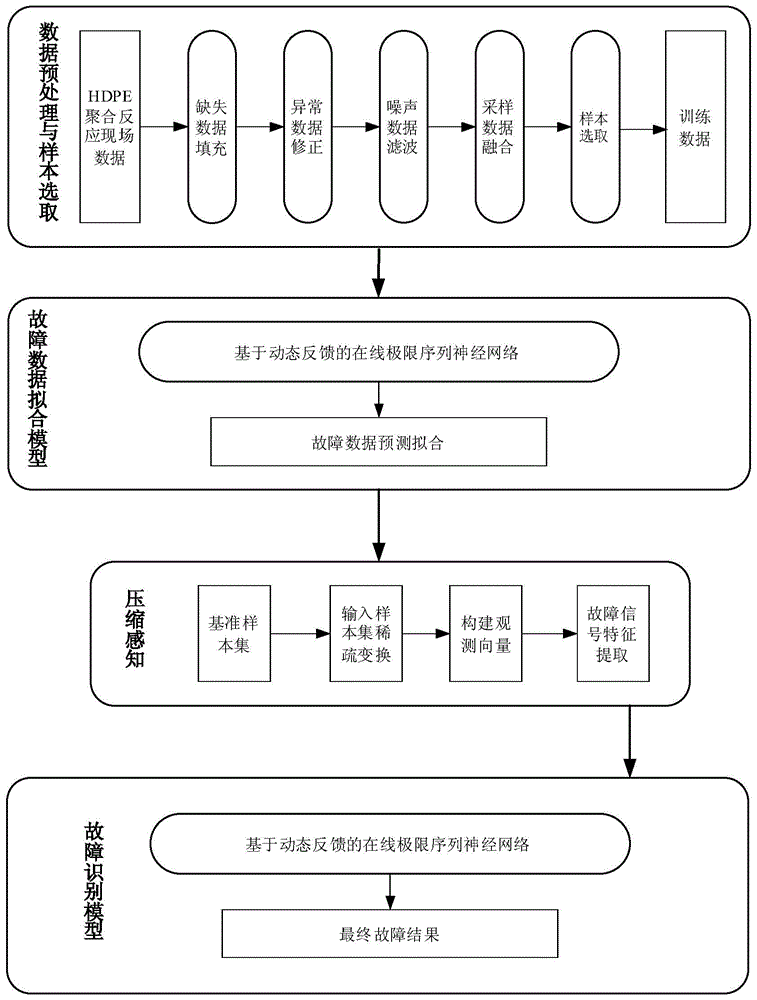

[0027] The invention provides a high-performance nonlinear process industrial fault prediction and identification method, which overcomes the difficulty of online fault prediction and identification in the nonlinear production process of complex industrial systems, applies compressed sensing and artificial neural networks to the industrial field, and constructs The fault prediction and recognition model based on compressed sensing feature extraction and dynamic feedback OS-ELM neural network (DROS-ELM) technology provides technical support for enterprises to ensure safe production, improve production efficiency and save production costs.

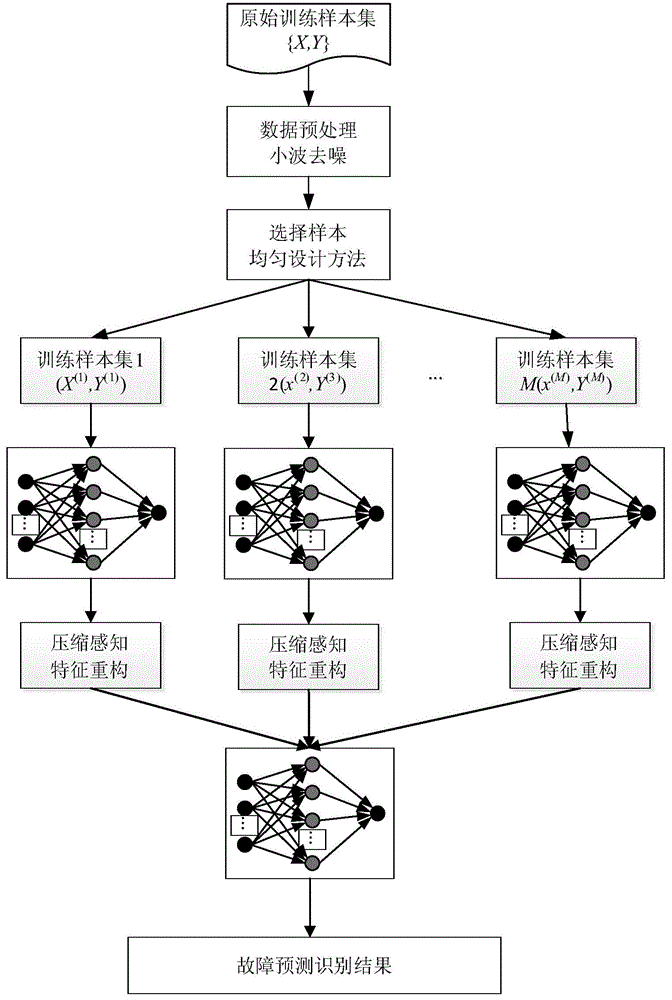

[0028] like figure 1 Shown is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com