Self-adaptive prediction function control method for nonlinear production process

An adaptive prediction and production process technology, applied in adaptive control, general control system, control/adjustment system, etc., can solve problems such as difficult algorithm implementation, difficult control of nonlinear process, irregular parameter adjustment, etc., to achieve system The effect of parameter adaptive optimization

Inactive Publication Date: 2010-08-25

CHINA PETROLEUM & CHEM CORP +1

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is that the nonlinear process existing in the prior art is difficult to control, modeling is difficult, algorithm implementation is difficult, parameter adjustment is irregular, etc., and an adaptive predictive function control method for nonlinear production process is provided

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

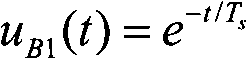

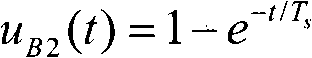

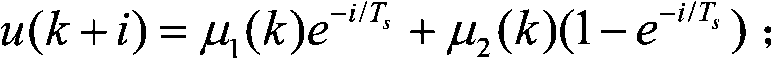

The invention relates to a self-adaptive prediction function control method for a nonlinear production process, which mainly solves the problems that the non-linear process is difficult to control and model and is complicate to calculate on line in the prior art. In the invention, an on-line self-adaptive algorithm is set by using on-lined acquired production data, constructing control input with two degrees of freedom and using an aggregation concept in economics without pre-building a predication model of an object to be controlled and comprises the following steps of: (1) building control input with two degrees of freedom: selecting control input of a future system, formed by weighting two primary functions; (2) building an expected performance index of the future system; (3) deducting future prediction output; (4) self-adaptively optimizing system parameters on line; and (5) stably analyzing a control system and then stably analyzing a novel control method according to the aggregation concept, a zooming theory and a prediction control theory, thereby obtaining a technical scheme for a parameter adjusting method of the control system and better solving the problems. The invention can be used for nonlinear industrial devices for oil refining, chemical industry, pharmacy, machinery, aviation and the like.

Description

technical field The invention relates to an adaptive predictive function control method of a nonlinear production process. Background technique Although most of the objects encountered in the actual industrial process are nonlinear, a large number of applications of predictive control algorithms so far are still based on linear model design, the most common ones are based on the application of step response models and impulse response models. These phenomena are mainly because the linear model can be directly identified from the input and output data, and the current application of predictive control is mainly concentrated in the petrochemical industry, and its control goal is to maintain the process in a desired steady state (regulation problem), rather than Rapid changes from one state to another (servo problem). And if the output measurement can be sufficiently accurate, a predictive model built around the operating point is sufficient to guarantee the stability and desi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05B13/02

Inventor 张彬杨为民吴智勇钱锋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com