Decentralized process monitoring method

A process monitoring, decentralized technology, applied in the direction of electrical testing/monitoring, which can solve problems such as difficult fault diagnosis, unsuitable faults, and weakened interpretability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

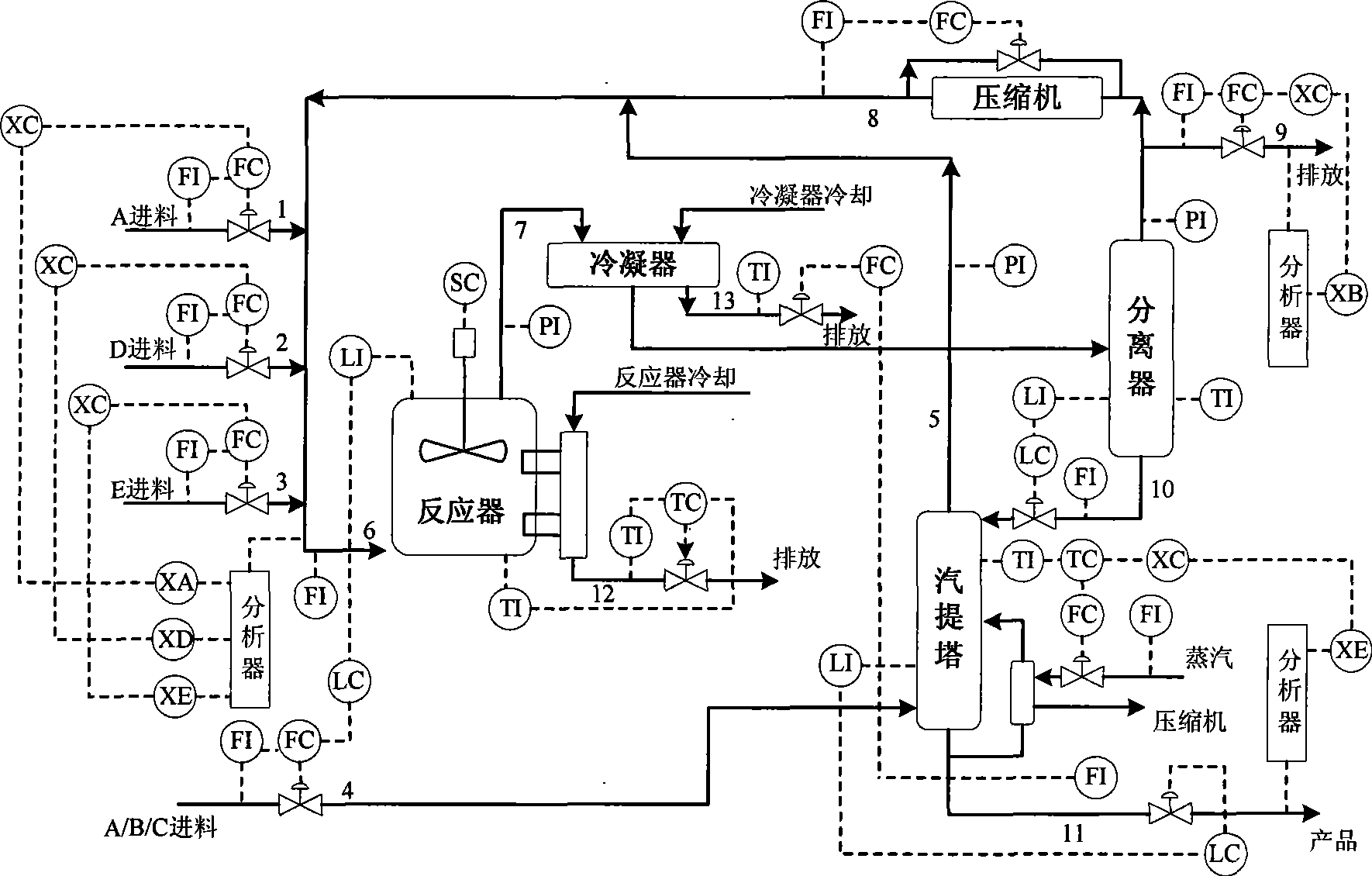

[0064] The method proposed by the present invention is applied to Tennessee-Eastman process simulation data. The Tennessee-Eastman process is a complex nonlinear process that was created by Eastman Chemical Company to provide a real industrial process for evaluating process control and monitoring methods. Control structures such as figure 1 shown. The process consists of five main units: reactor, condenser, compressor, separator, and stripper; moreover, it contains eight components: A, B, C, D, E, F, G, and H. The four reactants A, C, D and E are fed into the reactor together with the inert B to form the products G and H, as well as the by-product F. The Tennessee-Eastman process includes 21 preset failures, as shown in Table 1. Includes 22 continuous process measurements, 12 control variables, and 19 component measurements. As shown in table 2. A total of 52 observed variables were used in this study, except for the agitation speed of the reactor's stirrer (since it was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com