Application of fuzzy proportion integration differentiation (PID) algorithm in fuel cell radiating system

A fuel cell and heat dissipation system technology, applied in the direction of fuel cell additives, etc., can solve the problems of steady-state error, time-varying, and strong coupling of system output and control variables, uncertain battery operating parameters, and PID control that is difficult to achieve ideal results and other problems, to achieve the effect of strong adaptability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

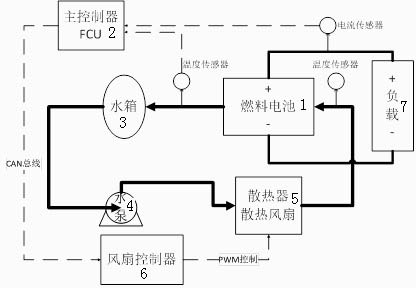

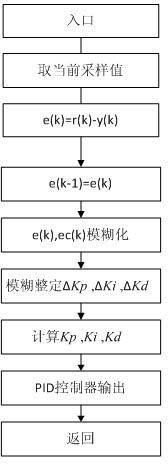

[0027] like figure 1 As shown, the fuel cell heat dissipation system includes a water tank 3 connected to the fuel cell 1, the water tank 3 is connected to the radiator and the cooling fan 5 through a circulating water pump 4 and corresponding pipelines, and a main controller (FCU) 2 passes through a temperature sensor and The current sensor collects the temperature and current data signals of the fuel cell and transmits them to the fan controller 6. The fan controller 6 controls the speed of the cooling fan, that is, controls the heat dissipation. figure 1 The medium load 7 is the fuel cell power supply object, the arrow indicates the flow direction of the cooling water in the heat dissipation system, the water pump 4 is responsible for executing the water cycle, the water tank 3 is responsible for storing the cooling water, and the corresponding speed of the heat dissipation fan is obtained through the fuzzy PID control algorithm to achieve the corresponding heat dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com