Fuzzy-PID compound control system for sintering-machine ignition furnaces

A composite control and furnace technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of weak anti-interference ability, poor precision, unsatisfactory accuracy, etc., to improve the sintering machine speed , reduce fuel consumption, and reduce sintering negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific embodiment of the utility model is described below in conjunction with accompanying drawing.

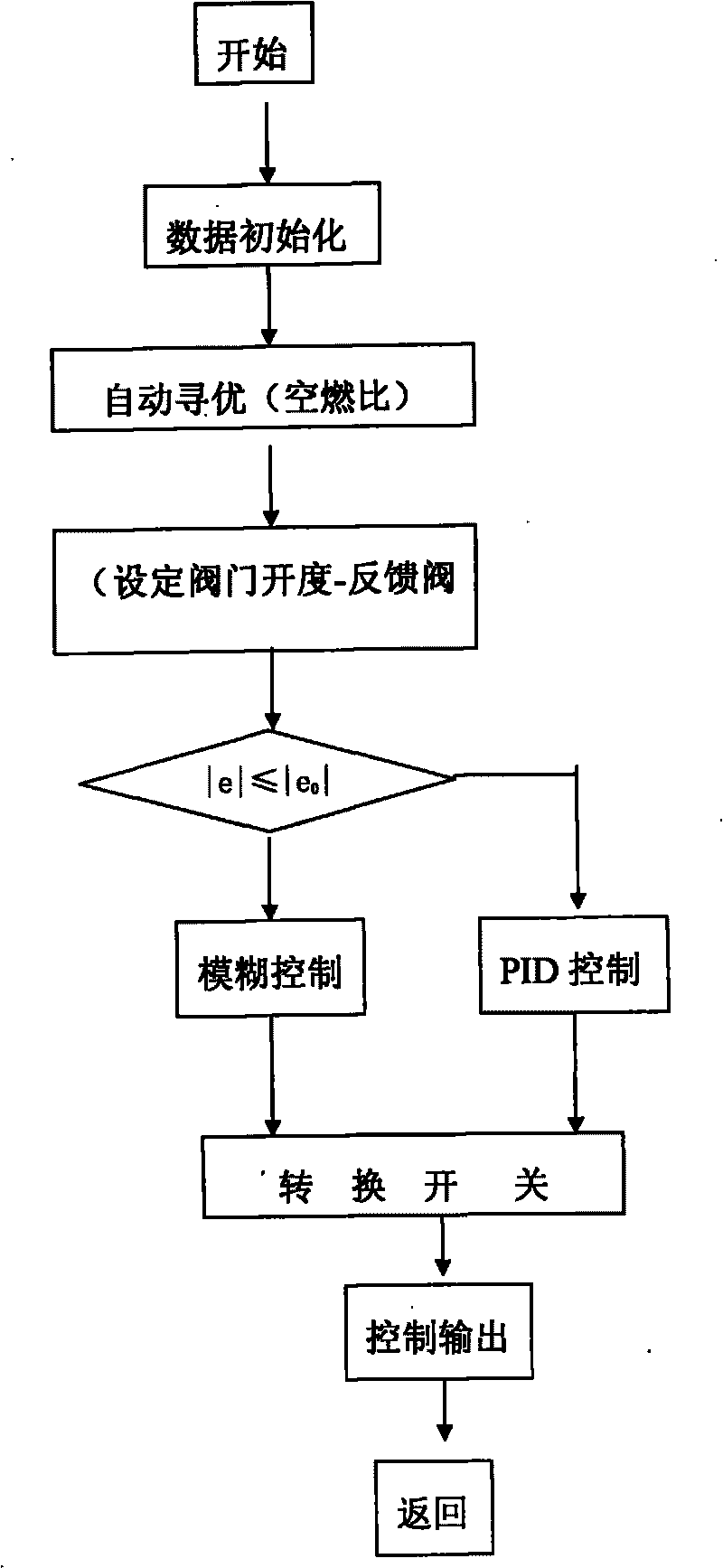

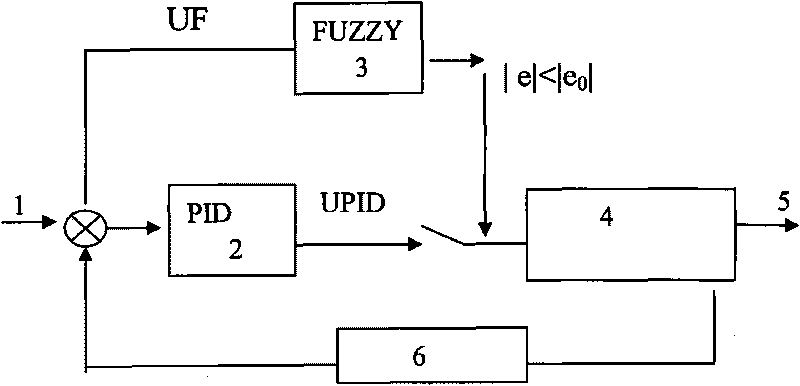

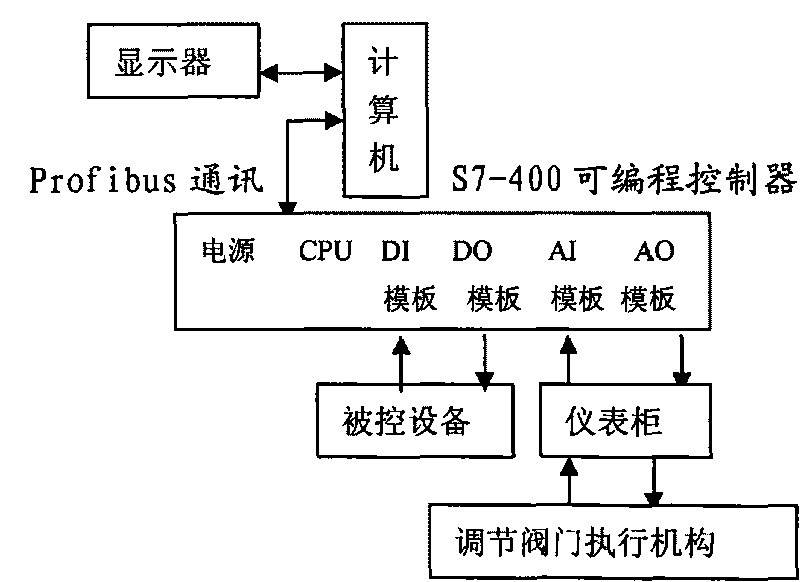

[0067] Such as figure 1 , 2 As shown, the Fuzzy-PID composite control system of the sintering machine ignition furnace of the present invention includes a PID control strategy, a detection instrument, and a control device, and is characterized in that the control flow of the Fuzzy-PID composite control program is:

[0068] 1) System data initialization,

[0069] 2) Automatically find a suitable air-fuel ratio,

[0070] 3) Set the difference between the combustion temperature and the feedback combustion temperature, and adjust the opening of the valve as the deviation value |e|,

[0071] 4) Determine whether |e|=|e 0 |, |e| is the deviation signal, |e 0 |When switching between Fuzzy and PID control, the given deviation,

[0072] 5) When |e|0 When |, adopt PID control strategy,

[0073] 6) When |e|>|e 0 When |, the fuzzy control strategy is adopted,

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com