Temperature control device for full-automatic injecting blowing plastic hollow molding machine and temperature control method thereof

A technology of temperature control device and temperature control method, which is applied in the direction of temperature control using electric mode, program control in sequence/logic controller, electric controller, etc., which can solve the problems of high system price, automatic adjustment of temperature control, and input cost major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

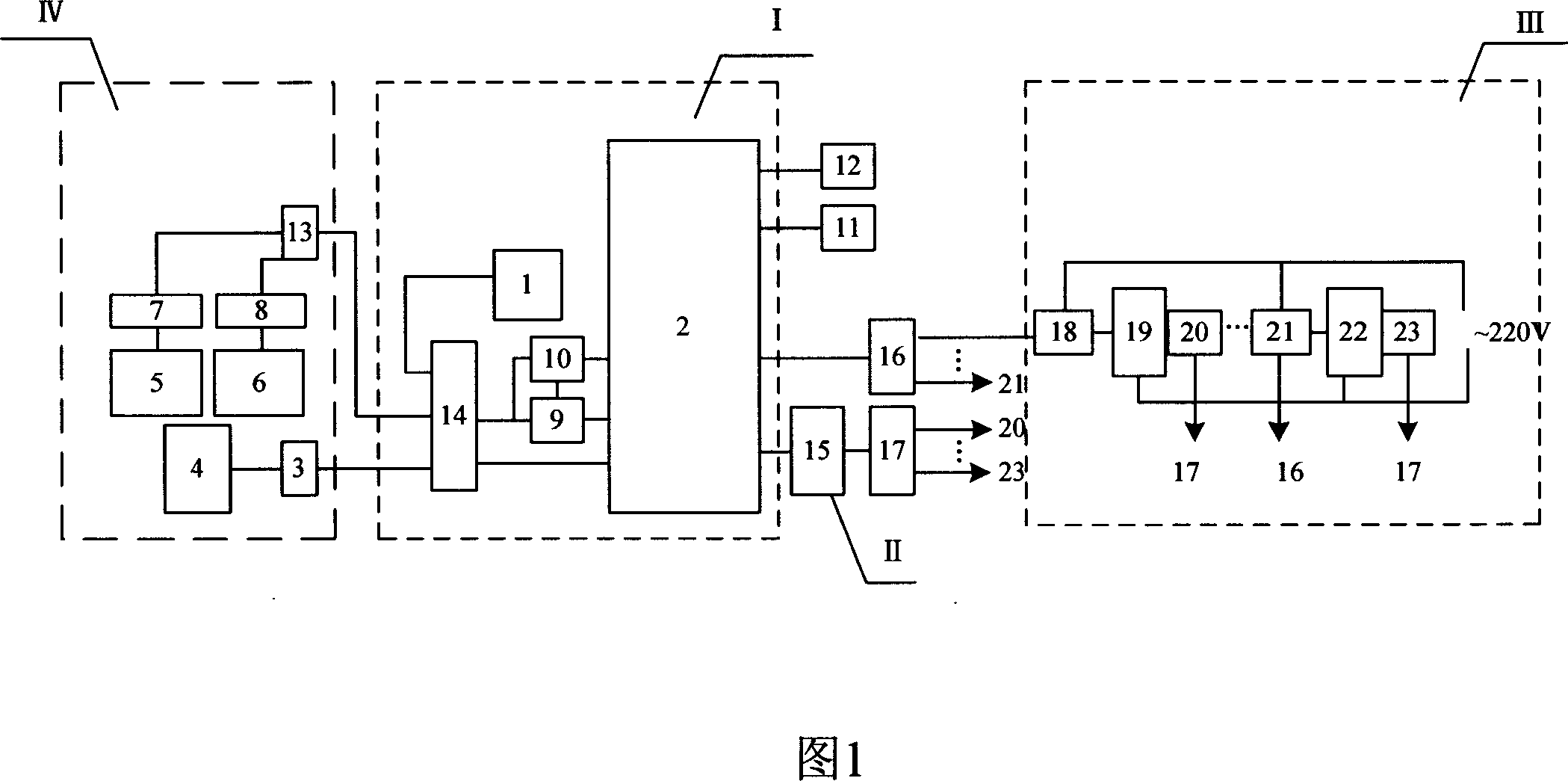

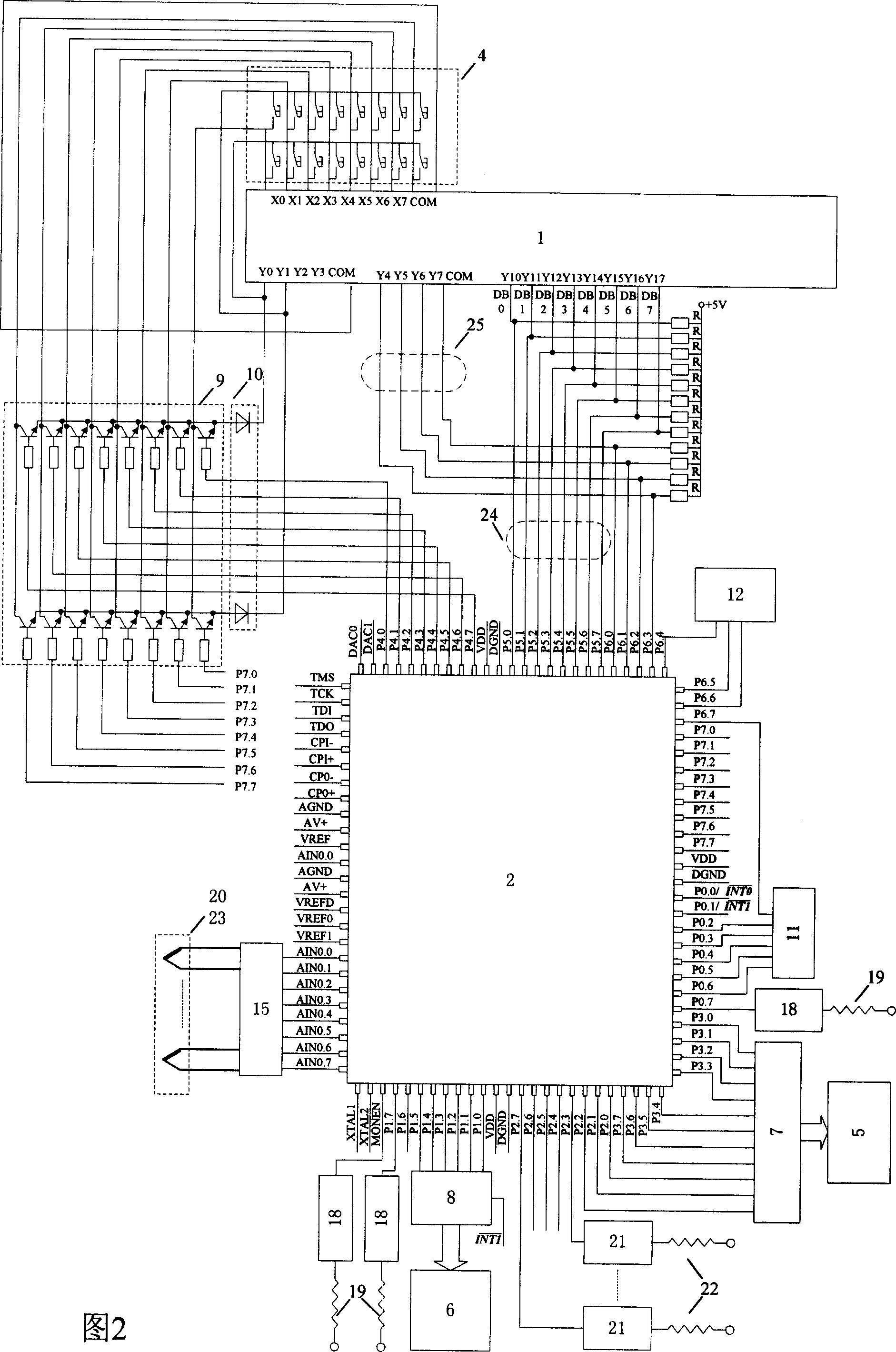

[0042] A full-automatic injection-blow plastic hollow molding machine temperature control device, composed of PLC-high-speed single-chip computer system I, temperature sensor signal amplification circuit II, heating device drive circuit III and operation panel IV;

[0043] As shown in Fig. 1 and Fig. 2: PLC-high-speed single-chip microcomputer system 1 is made up of PLC1, high-speed single-chip microcomputer 2, level conversion circuit 9, level direction control circuit 10 and PLC-high-speed single-chip microcomputer system circuit board 44, high-speed single-chip microcomputer 2, electric Level conversion circuit 9 and level conversion circuit 10 are installed on the PLC-high-speed single-chip microcomputer system circuit board 44;

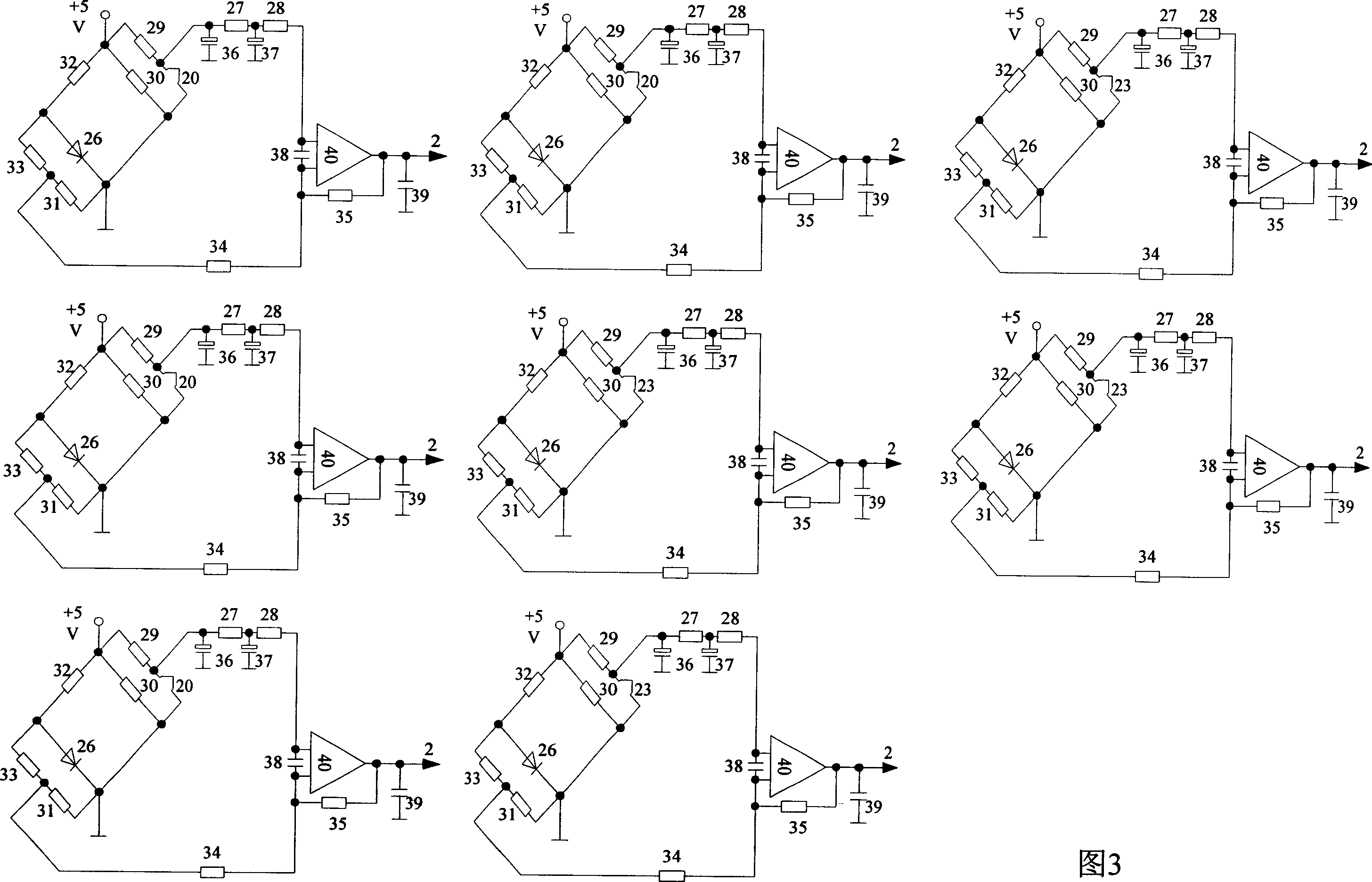

[0044] The temperature sensor signal amplification circuit II has 8 circuits, and each temperature sensor signal amplification circuit is composed of a bridge detection circuit, a low-pass filter, and an operational amplifier;

[0045] The heatin...

Embodiment 2

[0060] A method for controlling the temperature of the injection and blowing process of a fully automatic injection blowing plastic hollow molding machine, the method is to use the closed-loop fuzzy PID composed of PLC-high-speed single-chip microcomputer system, temperature sensor signal amplification circuit, heating device drive circuit and operation panel of the present invention The temperature control device realizes real-time temperature monitoring and regulation of the injection blowing process of the automatic injection blow plastic hollow molding machine; the temperature control setting value and temperature control parameters of the automatic injection blow plastic hollow molding machine are input from the buttons on the operation panel or the touch screen The high-speed single-chip microcomputer obtains various working status information of the automatic injection-blow plastic hollow molding machine from the 8-bit data bus and 4-bit address bus composed of PLC I / O po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com