Method and apparatus for measuring protection slag thickness in continuous casting crystallizer in

A continuous casting mold and thickness measurement technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of large differences in readings between different people, inability to use mold flux to measure, and it is difficult to accurately grasp the thickness of mold flux, and achieve accurate data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

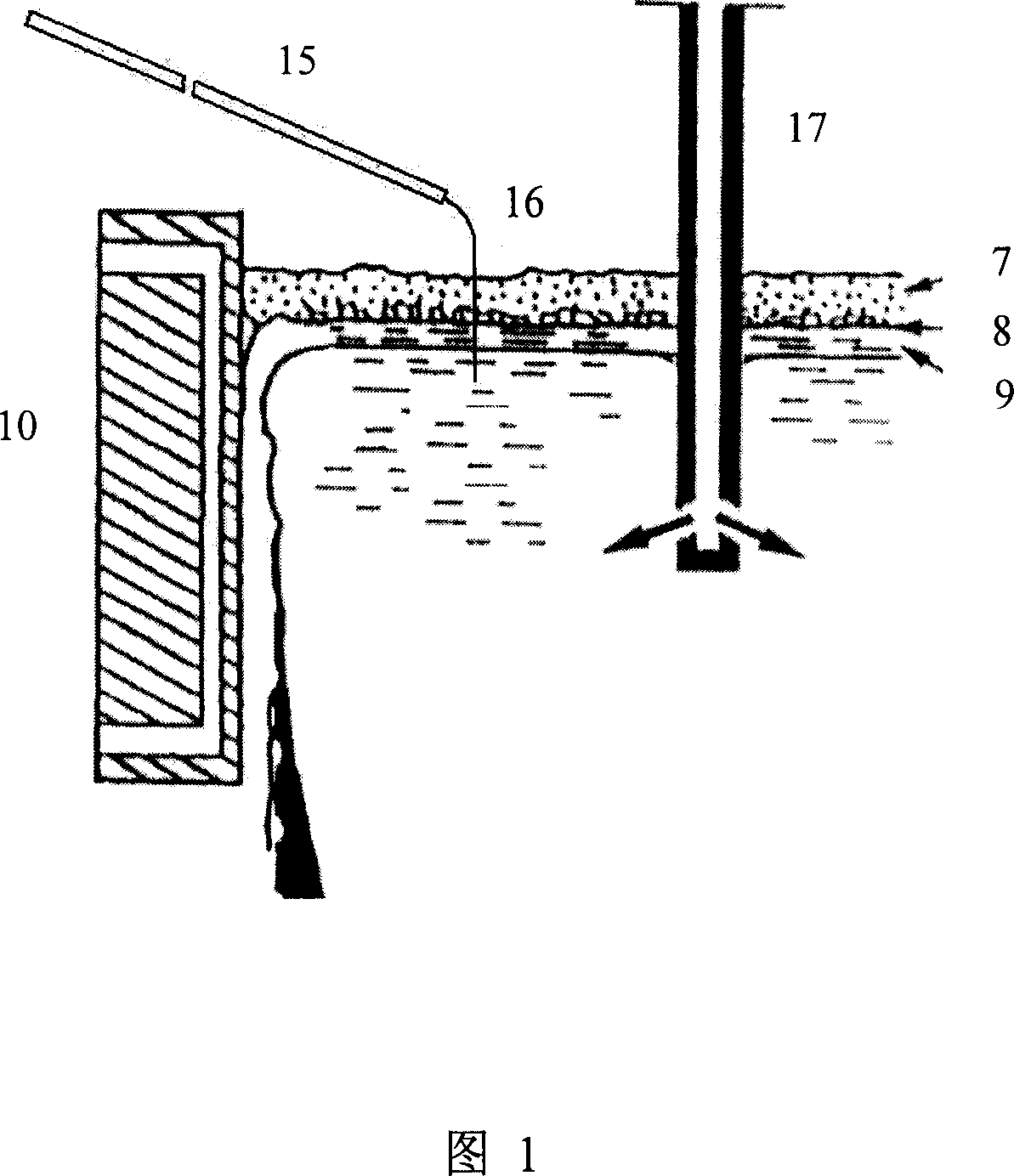

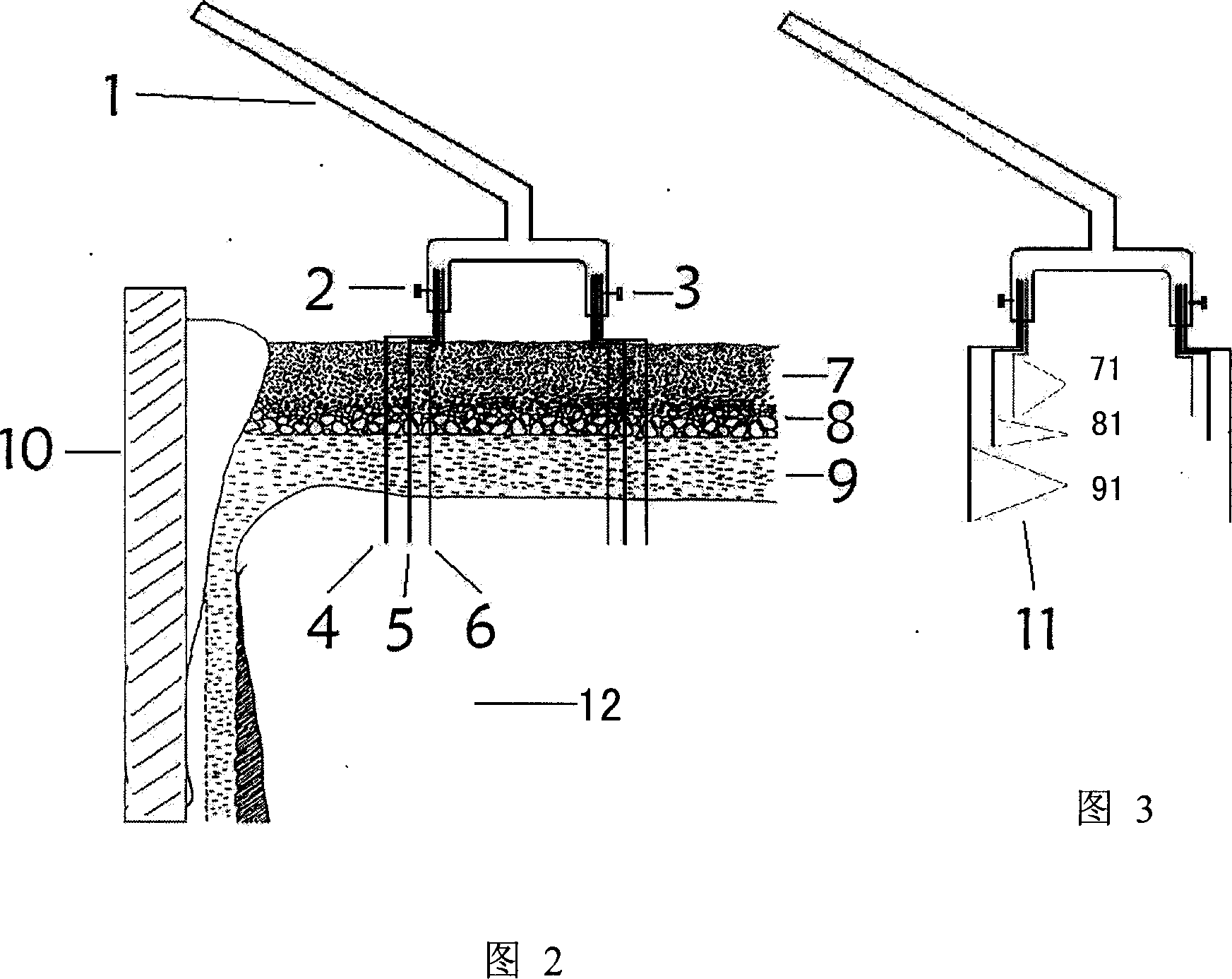

[0017] During the continuous casting production process, the mold slag in the crystallizer 10 will form three structures, namely the powder slag layer 7, the sintered layer 8, and the molten slag layer 9. Usually less than 600°C, the temperature of the sintered layer 8 is usually 700-1000°C, the temperature of the slag layer 9 is usually 1100-1500°C, and the temperature of the molten steel 12 cast from the tundish into the crystallizer 10 is usually above 1530°C. The temperature of the three-layer structure of slag is different, so metal wires with different melting points can be used to measure the thickness of each slag layer.

[0018] Referring to Fig. 2, the method for measuring the thickness of mold slag in the continuous casting mold of the present invention, its steps are:

[0019] Step 1, a set of three metal wires are respectively fixed on the two ends of the head of a Y-shaped frame 1 via bolts 2 and 3, and the two ends of the head of the Y-shaped frame 1 can be bent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com