Dual-thermocouple test apparatus for crystallization property of continuous casting mould casting powder

A continuous casting crystallizer and crystallization performance technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of low reliability of the production process, and achieve the effect of intuitive and reliable measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

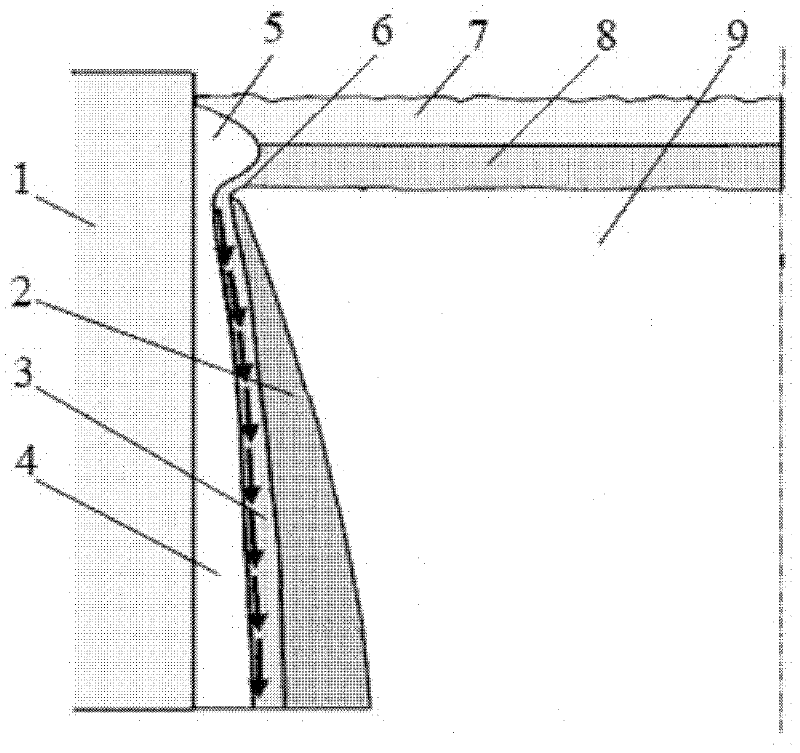

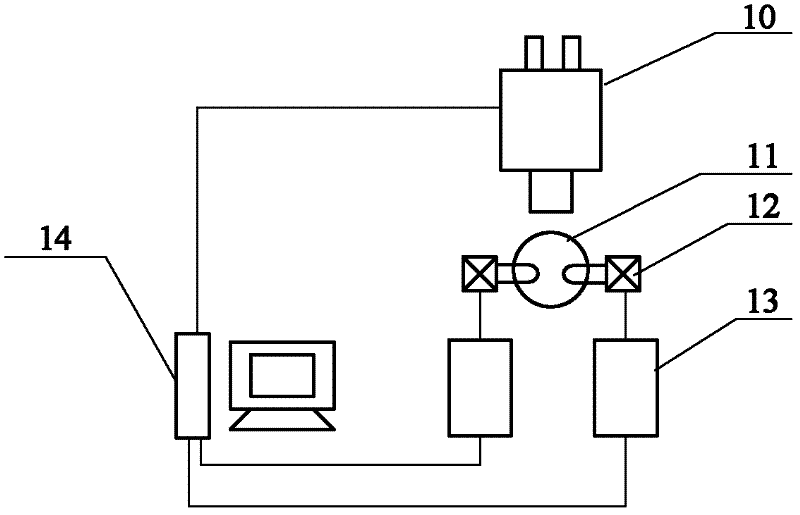

[0041] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

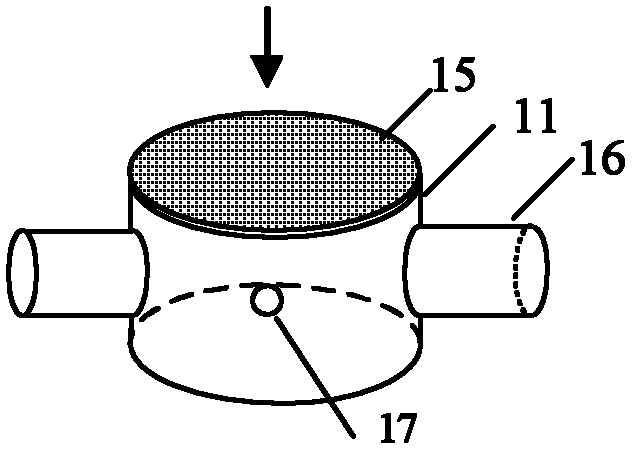

[0042] See attached figure 2 , 3 , 4, 5, the double thermocouple test device for the crystallization performance of continuous casting mold slag of the present invention includes an imaging device 10, a reaction chamber 11, a heating temperature measuring element 12, and a central processing unit 14, and the central processing unit 14 includes data acquisition device and image recording device; the reaction chamber 11 is a cavity made of transparent quartz glass, and two conduits 17 are symmetrically arranged on both sides; the imaging device 10 is arranged above the reaction chamber 11 and is connected with the central processing The image recording device in the device 14 is electrically connected; the heating temperature measuring element 12 is composed of two thermocouples, which are respectively inserted in the two conduit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com