Internal slag heat current inspector and inspection for continuously-casting crystallizer

A continuous casting crystallizer and heat flow detection technology, applied in the direction of material heat development, material thermal conductivity, etc., can solve the problems of unreliability and error, and achieve the effect of convenient operation, low equipment investment and maintenance costs, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

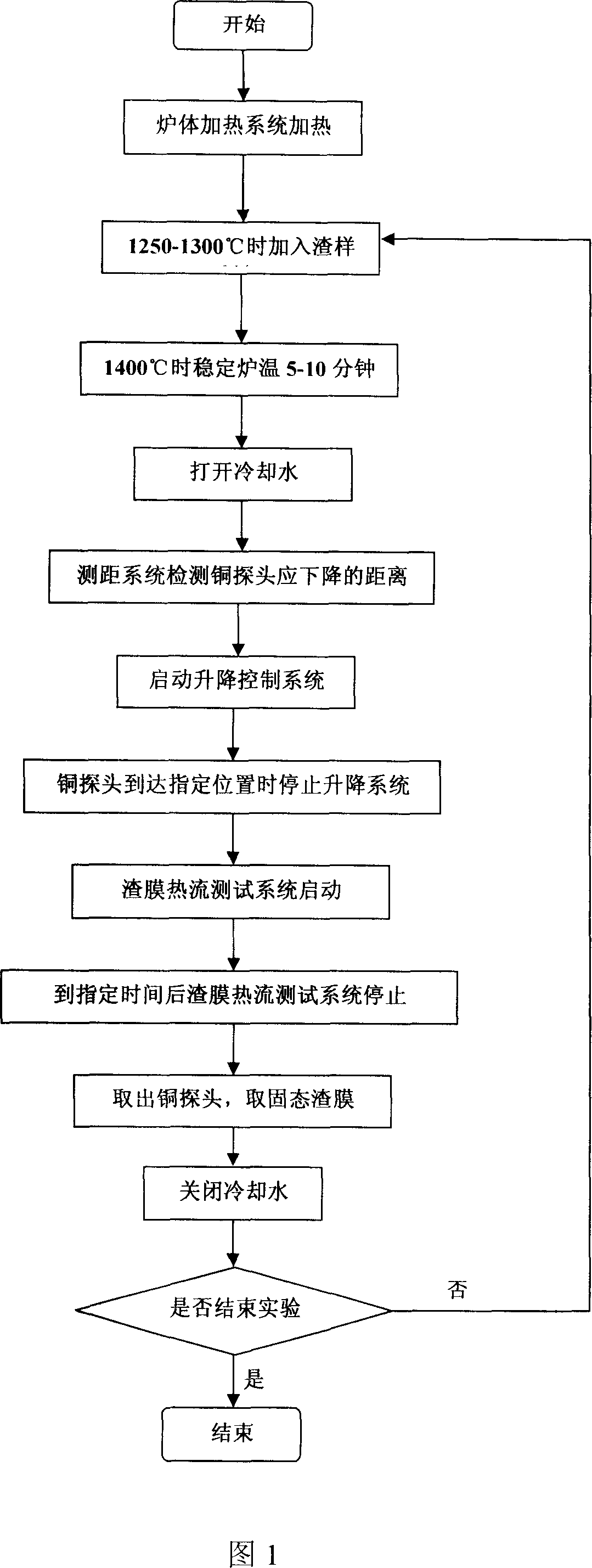

[0026] As in Fig. 1, the operating steps of the testing method of the present invention are:

[0027] 1. Mold flux sample preparation: Mold flux samples are prepared or prepared. The mold flux samples of the present invention can be formulas in the prior art, and there are certain differences in performance between mold flux samples of different formulas;

[0028] 2. Start the furnace body heating system to heat the furnace body and hearth;

[0029] 3. Add a molded slag sample with a set weight into the furnace body through a graphite crucible; usually put the slag sample when the furnace temperature reaches 1250°C-1350°C, and the weight added to the test device of the present invention is 250g-500g, usually 300g; for furnaces with different volumes, the weight of mold slag samples added is different, and the amount to be added is mainly determined according to its volume;

[0030] 4. When the furnace temperature reaches the set temperature, keep it warm for a period of time;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com